Courtesy: Caterpillar

The challenge was to take a facility that was far off the grid, and move it forward as an energy self-sufficient complex while also turning an idea into a commercially viable product. That was the impetus behind Caterpillar’s microgrid technology at the company’s Tucson Proving Ground testing facility in Arizona. The integrated solar and generator set system has been honored with POWERmagazine’s inaugural Commercial and Industrial Generation Award.

Finding a solution to a problem is often at the heart of innovation. The old adage, “There has to be a better way,” can be the driving force for a process that results not only in a short-term fix but also in a longer-term way to satisfy an existing market need.

That’s how it is with Caterpillar. The company may be best-known for manufacturing large equipment to aid construction projects, but it also has brought forth several technological innovations to help businesses in a variety of industries worldwide. When it was time to build a solution to solve a problem at one of the company’s own facilities, Caterpillar simply looked to its own team to find answers.

The project involved Caterpillar’s Tucson Proving Ground (TPG). The site, covering some 6,400 acres about 30 miles southwest of Tucson, Ariz., in an area known as Green Valley and adjacent to the Freeport-McMoRan Sierrita Copper Mine, is used for testing and validation along with product demonstration and training work for Caterpillar’s largest machines, such as those used by the mining industry. It is one of three such facilities Caterpillar operates worldwide.

The TPG, operated by Caterpillar’s Surface Mining and Technology (SM&T) division, opened in June 1990. (Caterpillar previously operated its Arizona Proving Ground in Litchfield Park, west of Phoenix, from 1945 to 1989.) The site is ideal for field trials of Caterpillar’s large equipment, but it is too remote to easily connect to a power grid, with the nearest service about eight miles away.

The site had received its electricity from three Cat C15 diesel generator sets (gensets), running 24 hours a day, seven days a week, 365 days a year, and using about 250,000 gallons of diesel fuel each year to power the TPG facilities. Caterpillar executives knew that to put sustainability—which the company today considers a core value—into practice, a new and certainly better generation system was needed.

“We need an extremely reliable supply of power to keep our facility running without interruption, so the system had to seamlessly blend solar and generator set power,” Darrin Johnston, customer solutions manager for new ventures in Caterpillar’s Global Power Solutions division, told POWER. The power system would not only need to work for the TPG, it also would make business sense for it to be a technology Caterpillar could tout as having commercial applications for power generation in other areas and for other industries.

So two Caterpillar divisions got together, along with other partners, vendors, an Arizona Caterpillar dealer, and several company staff members to develop a strategy for powering the TPG while also building a product other companies could use as a source of renewable energy. Enter the microgrid, a smaller, scaled-down version of a centralized power system, designed not only to generate electricity but also to distribute it and regulate its flow.

Microgrid Technology Takes Shape

“Caterpillar had explored hybrid power system technologies and demonstrated these technologies for several years,” Tony Cazzato, TPG facility manager and a member of Caterpillar’s SM&T division, told POWER. “In parallel, employees had suggested that TPG ought to look at solar power for the facility due to favorable weather conditions at the site. We have almost 320 days of sun [annually] in Green Valley!”

Cazzato said Caterpillar had adopted sustainability as a core value in 2012. “We also run a continuous improvement program where employees can submit ideas to management with suggestions to improve safety, quality, efficiency, and cost. Over the years we had multiple suggestions for reducing cost and improving sustainability by using renewables,” he said. “In recent years, reductions in the cost of solar power made the project more affordable and viable.”

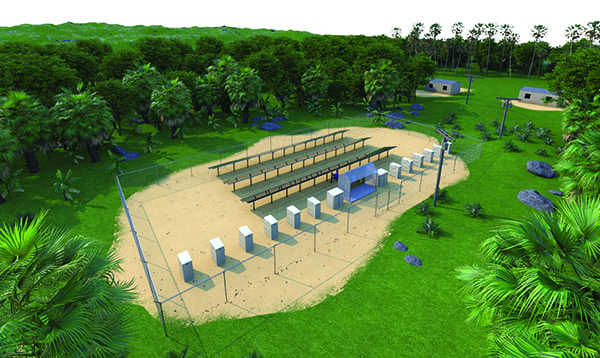

Caterpillar in 2016 installed 528 kWp DC (500 kWp AC) of photovoltaic (PV) solar panels (Figure 1) and 500 kW of short-term energy storage lithium-ion batteries and ultracapacitors to supplement the power from the gensets. The gensets are rated at 410 kW at 60 Hz. As Cazzato noted, the solar potential was obvious, with the site located in the Arizona desert.

The desert landscape would present some of its own challenges. “From a construction perspective, the property is quite hilly so we had to design a site and move some earth around to create a good location for the solar panels,” said Cazzato. “Fortunately, we are pretty good at moving dirt at Caterpillar.”

The site uses tracking solar panels, which follow the sun as it moves throughout the day, along with a fixed array, covering about two acres of the desert location. The Cat-branded solar panels were manufactured through a joint venture between Caterpillar and First Solar, a Tempe, Ariz.-based company that develops, engineers, builds, finances, and operates solar plants worldwide. The panels were installed by Empire Cat, a locally owned Caterpillar dealership.

“With our new solar array and energy storage system, we now get approximately 45% to 50% of our energy from renewables overall, and we are often able to shut down our diesel generator sets during daylight hours,” said Cazzato. “The project was something we wanted to do, but it took the right timing and circumstances for the project to take flight.”

Rick Rathe, the general manager of new ventures for Caterpillar’s Electric Power business, told POWER the company took into account “the declining cost of renewable energy sources and rapid advances in energy storage technology” when deciding to pursue the microgrid strategy. He noted it is a “financially viable way to incorporate sustainable sources of energy into our existing portfolio of traditional power generation offerings.”

Technical Specifications

Caterpillar’s experience with technological innovation and engineering across a range of industries proved invaluable for the project, which involved team members from across the company. When it was commissioned in May 2016, Dave Damerell, the global director of product validation, noted “The microgrid project has moved from concept to commercialization at an incredibly rapid pace, helping to bring sustainability to life here at TPG. It just goes to show you the power of collaboration and innovation. We can do big things when we work together.”

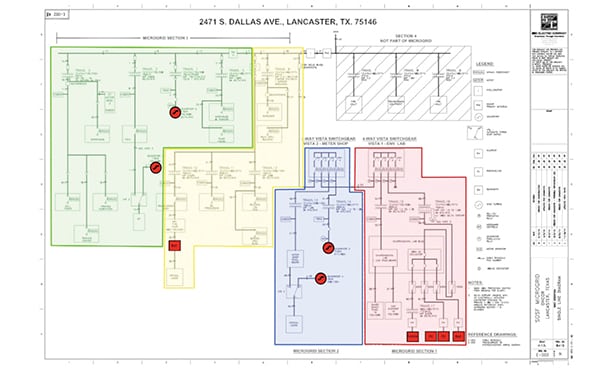

The innovation is obvious as the project uses a variety of Caterpillar-manufactured products (Figure 2).

|

| 2. Several parts working together. Caterpillar’s microgrid system has several elements, including solar, gensets, controls, remote monitoring, and energy storage. Courtesy: Caterpillar |

“We use Cat brand thin-film PV panels, a Cat Energy Storage System, Cat generator sets, and a Cat Microgrid Master Controller,” Johnston said. “Our solar array is made up of 4,800 panels of thin-film PV cells. At the time the microgrid was constructed, each panel was rated at 110 W of power for a total peak power capability of 528 kW DC.

“We connected these PV panels using 20 x 25 kW AC string inverters for a total output of 500 kW AC from the entire PV plant,” Johnston said. “Half of the panels are mounted on single-axis trackers that follow the motion of the sun. The other half are mounted as a fixed-tilt array.”

Because the sun is not always shining on the site, the microgrid uses bidirectional inverters and its energy storage system to balance the load, and the diesel gensets remain available as a redundant power source to ensure a reliable supply of electricity. As Johnston explained: “The system includes a Cat Energy Storage System (ESS) comprised of Cat Bi-Directional Power inverters, which connect ultracapacitors and lithium-ion batteries in parallel with the PV panels and the generator sets. This provides the system with unprecedented stability during transient power variation, improved power factor, as well as 12 minutes of supplementary power.”

The technology has proven itself as a viable source of power generation, and it also has proven efficient in terms of energy usage at the TPG, a major goal of Caterpillar’s sustainability initiatives. Johnston noted that the system includes integrated switchgear and is managed by a Cat Microgrid Master Controller (MMC) module (Figure 3). The microgrid technology allows for generator shutoff as needed, and visualization of the microgrid’s performance is provided by Cat Connect, the company’s web-enabled data and reporting service.

Cat Connect allows power plant operators, managers, and others to see the current and past operating states of the microgrid, and provides real-time awareness of any issues. It also documents whether the technology is saving the expected amount of fuel, and helps identify ways that the power system could be improved in its design and operation at the site.

“From an equipment perspective, the Cat Microgrid Master Controller and Cat Bi-Directional Power converter technologies accomplish [an integration of solar and genset power] while enabling roughly twice the fuel saving versus third-party controllers,” Johnston said. “These Cat products enable shutdown of all diesel generators to run on solar photovoltaic (PV) and energy storage alone during daylight hours when solar PV meets the site load. We also wanted to be able to track our usage and visualize the power management data to know that we are maximizing the savings from our renewable energy source, and our Cat Connect solution provides this visibility.”

Energy Savings

Providing energy to the TPG facility was the major goal of the microgrid project, but saving on energy usage at the site was also an important consideration for those working on the system.

“Before the microgrid, our generator sets used about 250,000 gallons of diesel fuel each year. With our remote location, [the fuel was] delivered by truck from Tucson. This is expensive and requires due diligence on the part of our logistics team to keep the fuel tanks full,” Cazzato said. “With the microgrid, we’ve been able to reduce our reliance on diesel, as well as lower engine maintenance and exhaust emissions. Using less diesel means fewer deliveries and increased energy security in case of a fuel supply interruption. The price of diesel fluctuates, of course, but the typical annual savings are expected to exceed $200,000, not including intangible benefits.”

Johnston said the installation of the solar panels, along with the energy storage system, has resulted in a substantial decrease in energy use at the TPG. “Generator set hour reduction is at least 25%,” he said. “The solar grid is providing 45% to 50% of the energy used at the site in an average month. During midday on a typical sunny day, and there are many in Arizona, 100% of the power is solar and the generators are off. On an annual basis, this translates into savings of roughly 100,000 gallons of diesel fuel. That results in a reduction of approximately 1,000 tons of CO2 emissions per year.”

Future Applications

Caterpillar’s microgrid strategy is led by the Global Power Solutions division’s New Ventures team. Caterpillar’s SM&T division has used the TPG as an example for potential customers, enabling them to see how the company’s microgrid technology works, with an eye toward installing it at other mine, industrial, and commercial sites worldwide.

The company has said it is focused not only on the technology as a renewable energy source for the developed world, but also considers it a way for undeveloped areas far off the grid to have access to a reliable, self-sustaining source of power (Figure 4). Caterpillar says the technology could serve rural communities, remote villages and islands, industrial sites, and other properties, bringing an efficient energy source to unserved or underserved areas. The company says it can design-to-order systems or do turnkey installations of units ranging from 10 kW to 100 MW.

“The Tucson Proving Ground is a proof point for similar microgrids that are now being installed for Caterpillar customers worldwide,” Rathe said. “These facilities include mining sites, remote villages, agricultural operations, manufacturing, commercial industrial, and more. For off-the-grid facilities like TPG that rely on diesel-powered generators for prime power, solar power offers some great financial benefits. It also offers sustainability benefits and it is a significant contributor to reducing exhaust emissions.

“Caterpillar utilizes sophisticated project modeling software to design power solutions for customers on and off the grid. This software, coupled with the power of the partnership between Caterpillar and the Cat dealers, makes the development of custom, often complex, projects easy and quick to install even in challenging environments.”

Caterpillar is supporting the development of its microgrid technology with investments in Fluidic Energy for energy storage, an agreement with First Solar for an integrated PV solar solution, and an equity investment in Powerhive, which provides energy solutions for emerging markets. ■

—Darrell Proctor is a POWER associate editor.