Fogging systems have been successfully used in the material-handling industry for more than 30 years to control explosive dust at transfer points. Today, fogging systems are an EPA Best Demonstrated Technology for subbituminous coal preparation plants.

The importance of properly managing fugitive dust emissions to ensure employee safety and equipment protection can’t be overstated. If you are a plant owner or operator who handles coal, then you are responsible for improving plant housekeeping, providing adequate employee training, and ensuring that the proper safety equipment is available and functional in the case of an emergency. I hear people say that safety is paramount at the plants I visit, yet many plants continue to ignore all the red flags when it comes to aggressively controlling fugitive dust, especially those plants that handle Powder River Basin (PRB) coal. There’s no longer any excuse for failing to have the best dust-management systems and practices.

A Brief History of Recent Coal Dust Standards

The hazards of combustible coal dust were the subject of an Investigation Report released by the U.S. Chemical Safety and Hazard Investigation Board (CSB) in November 2006. In this landmark report, the CSB reported on its investigation of dust explosions in general industry between 1980 and 2005. The CSB found that 281 combustible dust incidents killed 119 and injured 718 workers and “extensively damaged industrial facilities” in 44 states. The report concluded: “These findings illustrate the seriousness of the combustible dust hazard in U.S. workplaces, yet no comprehensive federal Occupational Safety and Health Administration (OSHA) standard exists to control the risk of dust explosions in general industry.”

OSHA responded by initiating a Combustible Dust National Emphasis Program (NEP), defining new standards to eliminate flash fires, explosions, and implosions caused by the ignition of accumulations of fugitive coal dust. (See “A Burning Concern: Combustible Dust,” POWER, May 2010.) The first release of the new NEP was on October 18, 2007, but a subsequent catastrophic explosion at a sugar refinery pressed OSHA to take more direct action against fugitive dust. It updated the NEP on March 11, 2008, noting that “OSHA is reissuing the directive (CPL03-00-008) on the Combustible Dust National Emphasis Program to increase its enforcement activities and to focus on specific industry groups that have experienced either frequent combustible dust incidents or combustible dust incidents with catastrophic consequences.”

Dry Fogging Is Now a Best Technology

One of the most cost-effective and direct means of controlling fugitive dust is using a dry fog system. The technology isn’t new. A 1981 article published in Coal Industry News discussed the use of dry fog for explosive dust control at Westvaco (paper mills) and Dayton Power & Light. In that article, Sonic, the developer of the dry fog dust suppression technology, predicted that “this new technology is going to have a major impact on coal handling in the years ahead.”

With recognition long over due, “fogging systems” were recently declared a best demonstrated technology (BDT) for coal-handing equipment used with subbituminous and lignite coals by the U.S. Environmental Protection Agency (EPA) in 40 CFR Part 60 “Standards of Performance for Coal Preparation and Processing Plants; Final Rule,” published October 8, 2009. BDT, as defined by the EPA, is the most effective commercially available means of treating specific wastes, in this case, fugitive dust emissions. Public testimony given to the EPA on fogging systems has confirmed that 29-year-old prediction: Dry fog can be the most cost effective dust control system available.

The BDT designation was due in part to the supportive testimony by representatives from PRB coal mines, PRB coal-fired plants, mining associations, Air Utility Group, and various state air regulators. Representatives from PRB coal mines and power plants testified that fogging systems have dramatically reduced capital and operating cost while simultaneously increasing dust control efficiency.

One PRB coal mine presented a detailed cost analysis of competing dust control technologies. Its study concluded that the total ownership cost of dust scrubbers was 50% more and replacement baghouses were 400% more expensive than using atomizing fog for dust control over a 30-year life cycle. Chemical systems are not BDT for subbituminous and lignite coals and therefore were not considered in this analysis.

The PRB mine analysis also estimated that baghouses use 2.5 times more energy than dry foggers.

Fogging Proved Better Than Baghouses

Why did it take regulators so long to recognize the importance of properly managing fugitive dust in general and the benefits of fogging systems in particular? According to David Gilroy of Dust Solutions Inc., “When the demand for PRB exploded in the early 1990s, PRB mines were very busy building new facilities and were required to install baghouse collection systems as BDT. Since this rush to build baghouses, there have been many baghouse fires and some violent explosions caused by the inherent properties of PRB coal. Power plants burning PRB coal were also having the same experiences.”

The CSB Investigation Report also found that 18% of all incidents and fatalities involved dust collectors such as baghouses.

The risk of fires, explosions, and noncompliance has prompted nearly every PRB coal mine and more than 100 coal-fired power plants to phase out mechanical dust collection in favor of a fogging system. With dry fog, there is no explosive exhaust stream.

One of the first PRB coal mines to make the switch to dry foggers was Triton Coal (now Black Thunder). The transition was difficult because regulators required the mine to keep the mechanical dust collection systems in service until they could demonstrate that the foggers worked at least as well as the mechanical systems. The foggers proved their value, and, as they say, the rest is history. Wyoming, the home of PRB coal, eventually permitted fogging systems as best available control technology (BACT) for PRB coal conveyor transfer points, giving fog systems a Zero Visible Emission Rating. Today, nearly every PRB mine has a fog system as part of its dust control strategy.

Word of the success of this “new” technology at the PRB coal mines trickled into the power generation industry, especially at plants that were converting to burn PRB coal. PRB coal mines are concerned about handling the coal from the mine to the freight cars. Coal-fired plants are concerned about unloading the coal, but they’re even more concerned about storing, handling, and pulverizing a coal with extremely friable outer layers that dry quickly, which makes more fines that increase the potential for baghouse fires and dust explosions. They soon became interested in the potential of fogging.

Fog System Application Guidelines

Like any technology, fog systems must be properly applied to achieve the desired results. With fog systems, a fuel-handling transfer point is a “scrubbing chamber.” Gilroy says that each chamber must be designed so that airflow is properly managed, such as by having adequately sized conveyor skirt covers at the conveyor load point. This is an important consideration for foggers because air movement must be slow so that the fog droplets injected into the transfer point will have sufficient retention time to attach to the airborne dust particles and settle them out on the belt. The design must have enough cover height for the air to expand and enough length for agglomeration to occur (Figures 1–4).

|

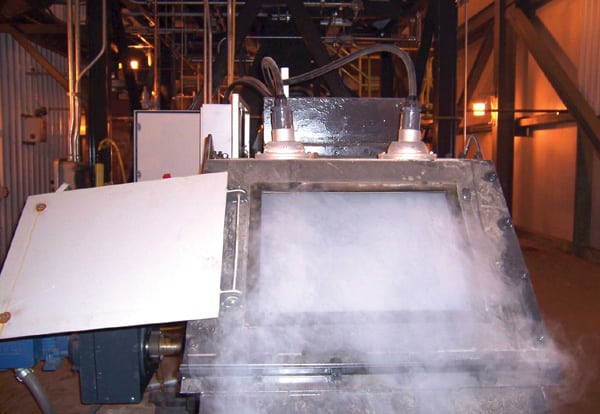

| 1. Gravity works. The Dust Solutions Inc. (DSI) dry fogging system agglomerates the airborne dust particles to micron-sized water droplets so that when the particles become heavy enough, they are returned to the product stream by the force of gravity. With conveyor transfer points, there must be sufficient room for the fog to fully develop, particularly in the receiving belt area. In addition, the conveyor skirt boards must be tight, and the inspection and conveyor covers must be in place so air leakage does not affect the efficiency of the system. Courtesy: Dust Solutions Inc. |

|

| 2. Blanket of fog. The system design is based on a unique nozzle design that can produce a very dense fog of 1- to10-micron-size water droplets that literally blanket the dust source and keep the dust particles from becoming airborne in this rail car unloading system. The DSI nozzle requires a maximum of 15 psi water pressure. Courtesy: Dust Solutions Inc. |

|

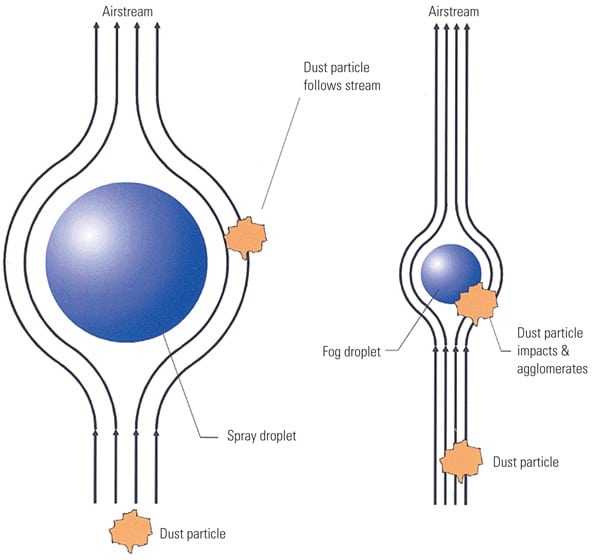

| 3. Droplet size matters. For agglomeration of the dust particles to occur at the dust source point, two conditions must occur: Enough water droplets of the same size as the dust particles must be present, and both dust and water droplets must be constrained to the same volume so that agglomeration can occur. If the water droplet’s size is too large, the dust particle will follow the air streamline and miss the water droplet. Source: Dust Solutions Inc. |

|

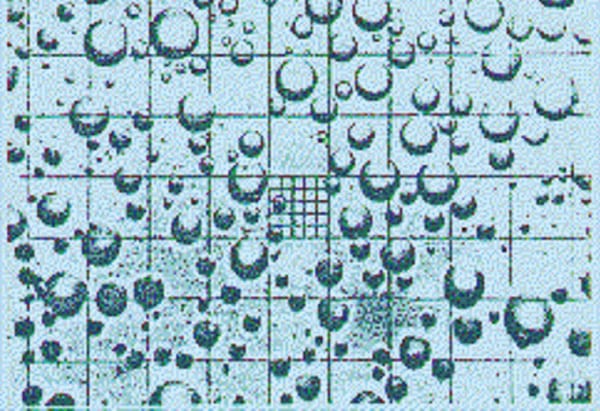

| 4. Micron-scale water particles. An actual high-speed photograph of droplets generated by a DSI fogger designed to produce water droplets less than 10 microns in diameter. The droplets were captured on a greased microscope slide in a chamber that was at 100% relative humidity to eliminate evaporation of the droplets. The small squares are 2 microns across. Any fugitive dust particles encapsulated by such densely packed fog droplets have little or no chance of escaping. Courtesy: Dust Solutions Inc. |

In the past few years, controlled-flow chutes have taken these principles one step further by shaping the material flow and reducing material impact within the chute. Gilroy notes that although some manufacturers claim to have a “dustless” transfer chute design, his customers say that controlled flow transfer points have helped reduce dust generation; however, in many cases, that is not enough, and a fog system must be added to achieve the desired results.

Gilroy pointed out an interesting recent project where dry foggers were added to an existing PRB coal-handling system. Dry Fork Mine (part of Basin Electric Power Cooperative) is a PRB coal mine that installed a passive control chute under a primary crusher to achieve the specified amount of dust control. The staff at Dry Fork Mine has long experience with fog systems, having previously replaced their mechanical dust collectors at the silo fill and conveyor transfer points. When the conveying system was designed for supplying coal from the mine to the Dry Fork Power Station now under construction, Basin Electric specified dry fog combined with passive control chutes for optimum control.

Basin Electric is also installing fogging systems at its new 400-MW Dry Fork Station in Gillette, Wyo. Each transfer point will use both a controlled flow chute and a fog system to achieve the highest degree of dust control efficiency.

—Dr. Robert Peltier, PE is editor-in-chief of POWER