Regardless of how much prevention is employed to mitigate combustible dust in coal-fired power plants, fugitive coal dust is pervasive and can be dangerous. In coal-fired power plants, mechanical transfer points are leading sources for airborne fugitive dust. However, because coal dust travels quickly over large areas with minimal airflow, fugitive combustible dust settles in many areas.

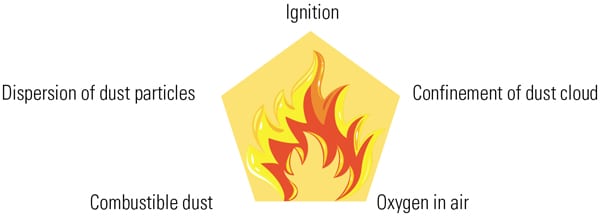

Primary dust explosions occur when combustible dust is present, forms a dust cloud (in sufficient amounts) in an enclosed environment with an ignition source and oxygen (Figure 3). If one were to put a flame to a layer of combustible dust on a desk, the dust would burn, but not explode. Fanning the dust with a piece of paper to make the dust particles airborne, however, would create a dust cloud that could blow up.

|

| 3. Explosive situation. Primary dust explosions occur when combustible dust such as coal dust is present, forms a dust cloud (in sufficient amounts) in an enclosed environment with an ignition source and oxygen. If any one of these elements is missing, there can be no explosion. Source: National Fire Protection Association |

Catastrophic secondary explosions occur when the force from the primary explosion dislodges fugitive dust that has been allowed to accumulate on walls, floors, and other horizontal surfaces such as equipment ledges, above suspended ceilings, and on other concealed surfaces, producing more dust clouds and creating a domino effect that causes further explosions.

Preventing Explosions by Using Appropriate Vacuum Cleaners

Bill Bobbitt of Bobbitt Associates Environmental Systems, who’s been working in the safety field for more than 25 years, said, “I always tell my clients, it not a matter of if, but when. Conditions have to be perfect and that ‘when’ can be 30 years from now, or it could be next week. But if you eliminate the fugitive dust, it cannot create a secondary dust explosion.”

The National Electrical Code (NEC) defines hazardous locations as those areas “where fire or explosion hazards may exist due to flammable gases or vapors, flammable liquids, combustible dust, or ignitable fibers or flyings.” Hazardous locations are classified in three ways by the NEC: type, condition, and nature. Class II locations are those areas made hazardous by the presence of combustible dust. Finely pulverized material, suspended in the atmosphere, can cause powerful explosions.

The NEC also specifies that hazardous material may exist in several different kinds of conditions, which, for simplicity, can be described as normal conditions (Division 1) and abnormal conditions (Division 2). In the normal condition, the hazard would be expected to be present in everyday production operations or during frequent repair and maintenance activity. When the hazardous material is expected to be confined within closed containers or closed systems and will be present only through accidental rupture, breakage, or unusual faulty operation, the situation would be called abnormal.

As the first line of defense in housekeeping routines to prevent catastrophic explosions caused by combustible dust and comply with regulatory agencies, plant personnel need to employ industrial vacuum cleaners that are built from the bottom up to be used in a variety of Class II, Division 2 areas (Figure 4). Redundantly grounded industrial vacuum cleaners are designed to shield workers and property from catastrophic secondary coal dust explosions.

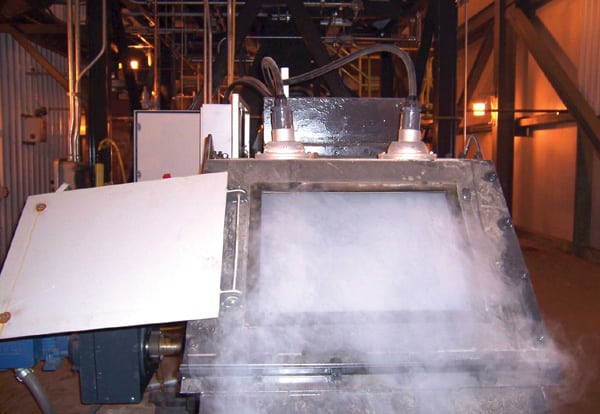

|

| 4. Housekeeping helper. Cleaning up the abundant dust around the boot seals in this cement plant is more effective with the VAC-U-MAX air-operated industrial vacuum cleaner than with shovels and wheel barrows. Courtesy: VAC-U-MAX |

Perils of Standard Shop-Type Vacuums

Any time there is powder flowing in one direction through a plastic vacuum-cleaning hose, it can create a significant static electric charge. In addition, there may be static electricity buildup on individual dust particles. If a charged, ungrounded hose used to vacuum combustible dust were to contact an object that was grounded, the static electricity could then arc and trigger a violent explosion. This is why the U.S. Occupational Safety and Health Administration (OSHA) has issued numerous citations for plant personnel using standard vacuum cleaners where Class II, Division 2 equipment is required under the law.

Bobbitt sees a number of standard shop-type vacuums in plants. “There are so many problems with them. They themselves are hazards in an industrial environment,” he said. First and foremost, they are not grounded or classified for Class II, Division 2 areas. In addition, they can shock workers and they clog easily. Not surprisingly, the workers don’t want to use them, and if workers don’t use them, fugitive dust continues to accumulate in the plant.

Recently, Bobbitt discussed challenges with using Class II, Division 2 electric vacuums at a meeting of the Kansas City Power & Light (KCP&L) Coal Handling Group, where safety professionals from each of the KCP&L power stations came together to discuss proactive solutions to safety challenges. He described a recent incident in which he was shown five different expensive Class II, Division 2 electric vacuums sitting in a warehouse at a power plant not being used. Plant personnel told him that they did not want to utilize the equipment because after 20 minutes of use, the filters would bind. In addition, they were reluctant to use them because they continually had to lift the head from the vacuum cleaners and tap the cake off before they could achieve the appropriate suction levels.

This same power plant, and its five sister facilities, “now use a Class II, Division 2 air-powered VAC-U-MAX model with a pulse-cleaning system on the filters, that with the push of a button releases the dust from the filter and allows the user to resume cleaning,” Bobbitt said.

The VAC-U-MAX company developed the first air-operated industrial vacuum in 1954 and has been the pioneer in solving vacuum-related challenges in a wide range of manufacturing and industrial settings (Figures 5 and 6).

|

| 5. Intrinsically safe systems. The VAC-U-MAX compressed air–powered vacuums meet regulatory requirements for grounding and bonding. Employing this type of industrial vacuum cleaner that is redundantly grounded eliminates the possibility of any kind of explosion from the vacuum. Courtesy: VAC-U-MAX |

|

| 6. Modularity maximizes usage. Like the VAC-U-MAX central vacuum system shown in Figure 5 that has an explosion vent, most vacuums are modular in nature. Standard equipment with additional capabilities can be added to the vacuums for specific applications. Courtesy: VAC-U-MAX |

Advantages of Redundantly Grounded Industrial Vacuum Cleaners

Employing an industrial vacuum cleaner that is redundantly grounded in five different ways “eliminates the possibility of any kind of explosion from the vacuum,” Bobbitt explained. Although VAC-U-MAX does produce electric vacuums designed for Class II, Division 2 environments, the most economical solution for cleaning combustible fugitive coal dust is the company’s air-operated vacuums. This type of vacuum is safer in terms of grounding, and it also works more efficiently in the industrial environment.

Beyond the fact that VAC-U-MAX air-operated vacuums use no electricity and have no moving parts, the first of the five ways that these vacuums are grounded begins with the air line that supplies compressed air to the units. Because most plants have compressed air lines made from iron that conduct electricity, the company’s air-operated vacuums use static conductive high-pressure compressed air lines. In addition to the static conductive air lines, static conductive hoses, filters, and casters are employed to further reduce risk. Furthermore, a grounding lug and strap that travels from the vacuum head down to the 55-gallon drum is used to eliminate the potential for arcing.

Bobbitt added that when you are dealing with explosive dust, you may need a Class II, Division 2 vacuum cleaner in a non-Class II, Division 2 area. “You might have small quantities of explosive dust, and it might take a very hot and prolonged source of ignition, but with OSHA’s Combustible Dust National Emphasis Program (NEP), facilities need to be very careful that they comply because there are a lot of questions as to what compliance means,” he said.

Housekeeping violations ranked second in citations under the NEP “with respect to combustible dust related hazards,” according to recent OSHA statistics. In addition, the agency issued citations for “General Duty Clause” violations involving the practice of blowing dust with an air compressor and not using electrical equipment that was designed for hazardous (classified) locations. In fact, in the Electric Services Industry Group from October 2010 through September 2011, the General Duty Clause violation category was one of the top 10 violation categories most frequently cited by OSHA.

“Although the regulations for combustible dust aren’t real clear, I find that a lot of companies are trying to get better at general housecleaning,” Bobbitt said.

—Contributed by Doan Pendleton (info@vac-u-max.com), vice president of marketing and sales at VAC-U-MAX.