The Great Plains Power Station in Saskatchewan supports SaskPower’s effort to add generation capacity in support of the province’s rapidly growing industrial sector.

Canadian power company SaskPower is in the midst of executing a long-term strategy to modernize and expand its provincial electrical system. The plan includes upgrading and replacing historical generation, while supporting ambitious growth plans for an expanding Saskatchewan market with agriculture, mining, and data integration at the forefront of power generation needs. The company in the last year alone invested $1.5 billion in capital projects, adding power generation capacity through the construction of new power plants along with upgrading existing facilities.

The Great Plains Power Station is a linchpin project for the company’s future supply plan. Great Plains is a 370-MW combined cycle gas turbine facility located at the Moose Jaw Industrial Park south of Moose Jaw, Saskatchewan. Burns & McDonnell, which led the engineering, procurement, and construction (EPC) for the project, said Great Plains supports SaskPower’s commitment to provide reliable and affordable power to the province of Saskatchewan as it supports local and regional growth.

Construction of Great Plains began in March 2021. The plant entered commercial operation in December 2024. The project contributes to SaskPower’s goal of achieving a net-zero greenhouse gas emissions power system by 2050, as well as servicing necessary load within SaskPower’s strategic plans.

Scott Strawn, senior vice president and general manager of the Power Global Practice at Burns & McDonnell, told POWER the power station has already provided a model for future natural gas-fired power projects. “Unlike the large-scale 1,200-plus-MW plants routinely designed and constructed in the U.S., the Saskatchewan grid system and power needs do not support such high-capacity single-source loads. Instead, this project demonstrates a more strategic generation distribution approach with plant sizes in the range of 300 to 370 MW, which are point loads that align with the capacity limits and distribution needs of the regional grid,” he said.

“This configuration has proven to be effective and we believe it is now considered the model for future development,” said Darcy Wagner, managing director for Canada with Burns & McDonnell. “Moreover, the plant’s design and capacity are intended to integrate seamlessly with other forms of power generation, including simple cycles, renewables, reciprocating engines, and baseload nuclear power, allowing for a more balanced and resilient energy mix.”

Great Plains’ role in helping meet SaskPower’s goals, and its importance to the whole of Saskatchewan, is among the reasons the facility is receiving a POWER Top Plant Award for natural gas–fired generation.

Local Workforce

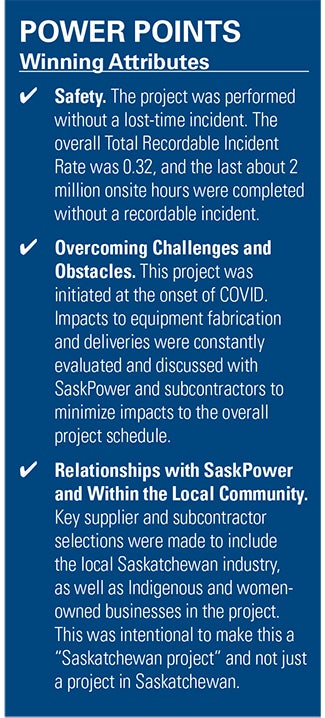

The principals on the Great Plains project worked with more than 300 Saskatchewan-based companies, including fabricated steel, piping, tanks, and general construction material suppliers. Those companies also included civil, mechanical and electrical subcontractors, and various construction service and rental companies. The project recognized contract awards that far exceeded the targets established at the onset of the project for local and Indigenous-based companies ($334 million to local companies, $52 million to Indigenous companies).

Burns & McDonnell said there were more than 600 workers onsite during peak construction, including many from Saskatchewan businesses and skilled tradespeople, both unionized and non-unionized. Most of the construction crew consisted of workers from local Saskatchewan businesses, and local tradespeople. The site permanently employs 25 workers.

Numbers tell much of the project’s story. The combined total labor of all workers for the project was 2.9 million hours, many of those hours worked directly within a global pandemic.

“The construction of the project faced numerous challenges, many of which were linked to the timing of the project being contracted just before the COVID-19 pandemic. As the pandemic evolved, it introduced economic, labor, and delivery schedule challenges,” said Jerry Gander, EPC project manager for Burns & McDonnell. “Impacts of COVID-19 in foreign countries, where many of the project’s specialized parts and pieces of equipment were sourced, challenged schedules. Additionally, strict adherence to continuously updated COVID-19 protocols restricted activity on the construction site, creating logistical complications.”

Said Gander, “Even as restrictions were lifted, the labor market never fully rebounded, with estimates upwards of 10% for permanent departures in the workforce in Saskatchewan. This created challenges in labor attraction, requiring the team to maintain a high level of transparency with SaskPower and work closely with them to develop appropriate action plans. Despite these obstacles, the team was able to draw on its familiarity with subcontractors and prior experience working in Saskatchewan to help manage and mitigate many of the challenges.”

Concrete and Steel

Construction at Great Plains included about 11,200 cubic meters of concrete, the equivalent of 4.5 Olympic-sized swimming pools—and also equivalent to filling the entire stadium that is home to the Saskatchewan Roughriders of the Canadian Football League with 1.5 meters of concrete. Burns & McDonnell said it’s enough concrete to fill about 1,400 standard-size concrete mixing trucks.

The project also includes 3,400 metric tons of steel, about 1.2 times the amount of structural steel used for the Roughriders stadium, and comparable to the steel used in 28 Boeing 737 airplanes. The power plant also has more than 20,000 meters of pipe (about 2.25 times the height of Mount Everest). Laid end-to-end, the piping would stretch roughly one-third of the way from the town of Regina, Saskatchewan, to Moose Jaw.

|

|

1. A Siemens Energy F-class gas turbine arrives at the Great Plains Power Station. The turbine was among many pieces of equipment that were built elsewhere and transported to the power plant. Courtesy: Stacia Marie Portraits |

Several companies had meaningful responsibilities in the project. Siemens Energy provided the gas turbine generator (Figure 1) and steam turbine generator, while Nooter/Eriksen supplied the heat recovery steam generator. Hyundai provided large transformers. Evapco Dry Cooling supplied the air-cooled condenser. Allan Construction handled civil construction, with PCL Energy providing mechanical construction and Graham Electric handling electrical construction. The plant sources its natural gas from SaskEnergy and TransGas.

Overcoming Challenges

The project also provided lessons in strategic engineering solutions. Gander told POWER: “Weather was another challenge, particularly due to the cold weather construction conditions common in Canada. To mitigate this, one of the first steps in construction was building a weather-tight structure to create a controlled environment for indoor work. The project team carefully scheduled and sequenced the concrete work to be completed before the onset of winter.”

The project also provided lessons in strategic engineering solutions. Gander told POWER: “Weather was another challenge, particularly due to the cold weather construction conditions common in Canada. To mitigate this, one of the first steps in construction was building a weather-tight structure to create a controlled environment for indoor work. The project team carefully scheduled and sequenced the concrete work to be completed before the onset of winter.”

Gander noted, though, that “some weather-dependent tasks still had to be completed during the colder months under temporary cover with heating in place to maintain suitable conditions. Transport and equipment deliveries were also impacted by spring thaw restrictions, necessitating coordination with the government to find workable solutions.”

“The engineering and design concept for Great Plains Power Station was to leverage continuous improvement opportunities that were realized through the design, construction, startup, and operation of Chinook Power Station,” said Weldon Stubbs, EPC project manager with Burns & McDonnell. “Working collaboratively with SaskPower, Burns & McDonnell, to the extent possible, replicated the technology [gas and steam turbines plus key balance of plant, or BOP, equipment] from Chinook. This streamlined the layout and engineering efforts and provided consistent equipment, allowing SaskPower to aggregate spare parts and staff training.”

Stubbs told POWER, “SaskPower and Burns & McDonnell worked as an integrated team in the design approval process through regular design meetings throughout the project. During the engineering and design phase, multiple 3D model review meetings were conducted with the SaskPower project team’s maintenance and operations representatives to review equipment access and maintenance requirements as the design and procurement of the equipment were finalized. During the construction phase of the project, a specific maintenance and access meeting was conducted periodically as equipment was installed so that any outstanding issues could be addressed. Additionally, working 3D models were delivered to SaskPower monthly to support review of operability and maintenance concerns.”

The plant used some pre-fabricated equipment, which was delivered to the work site from areas across Canada, the U.S., and Europe. Stubbs said items prefabricated and transported to site include the gas turbine generator, which was assembled in North Carolina and then transported by train. The steam turbine and steam turbine generator were manufactured in Germany, and delivered via ship and then train.

The heat recovery steam generator stair tower was prefabricated by Saskarc in Oxbow, Saskatchewan. The 52-meter-tall exhaust stack was prefabricated into two sections by JNE Welding in Saskatoon, Saskatchewan. Miscellaneous pump skids, instrument racks, and critical piping were prefabricated by AZCO Inc. in Appleton, Wisconsin. General service piping and inline components were prefabricated and spooled by Canadian Plains Energy Services in Emerald Park, Saskatchewan. Two power control modules, or PCMs, were prefabricated by ABB Inc. in Tea, South Dakota.

Wagner said, “This plant was pivotal in expanding Burns & McDonnell’s EPC footprint in Canada and deepening our longstanding partnership with SaskPower. It served as a blueprint for integrating local, Indigenous, and women-owned firms into our subcontracts. By collaborating directly with SaskPower and Saskatchewan-based contractors, we were able to harness the construction and other professionals that were local to the area. The project underlined our commitment to transparency, local engagement, and inclusive procurement, setting the standard for future success in the region.”

—Darrell Proctor is a senior editor with POWER.