Hydrogen Pilot Validates Fuel-Blending Projects

The successful test of blending hydrogen with natural gas at a power plant in Michigan can be a model for the power generation industry.

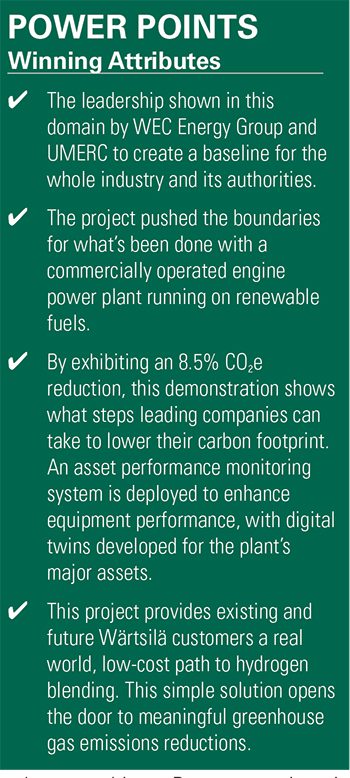

The use of hydrogen to fuel power generation is on the rise, with several manufacturers building turbines and engines capable of burning hydrogen to produce electricity. The U.S. Environmental Protection Agency’s recent move to adopt new standards on carbon emissions is expected to advance hydrogen’s use in the power sector. Some groups already are involved in hydrogen research, including Wärtsilä. The technology company, in collaboration with WEC Energy Group, WEC subsidiary utility Upper Michigan Energy Resources Corp. (UMERC), the Electric Power Research Institute (EPRI), and Burns & McDonnell, carried out a hydrogen fuel testing project at UMERC’s A.J. Mihm Power Plant in Pelkie, Michigan.

The testing at the Mihm facility, completed in October 2022, was important as a measure of how the use of hydrogen could reduce the carbon footprint of an existing natural gas–fueled power plant. It is likely to be a model for how utilities and power generators pursue the use of hydrogen as part of a decarbonization strategy. It also is the recipient of POWER’s 2023 Hydrogen Award.

“The most efficient way to develop and validate new engine concepts is in our engine test laboratories where we have the freedom to really test the limits of our engines. But to credibly prove our products and solutions in actual conditions, field tests together with customers are essential,” said Jon Rodriguez, Energy business director—Engine Power Plants for Wärtsilä Energy. “Especially for new sustainable fuels, like hydrogen, ammonia, and methanol, it’s not only about demonstrating the capabilities of the engines, but to also provide first-hand experience and knowledge to the customer for how the setup works and how it will impact the plant operation.”

Reducing Emissions

The Mihm project aligned with WEC’s goal to reduce CO2 emissions from its electric power generation fleet by 60% by the end of 2025. The utility also wants to reduce carbon emissions by 80% by the end of 2030, compared to 2005 levels. WEC officials have said they want their operations to be net carbon-neutral by 2050.

“WEC Energy Group and UMERC deserve recognition for their initiative to take real action and establish proof for how balancer power plants can play a key role in the future decarbonized U.S. energy industry,” said Fredrik Ostman, product manager, Fuel Conversions and Decarbonization, at Wärtsilä Energy. “EPRI’s role in this project was to increase the value of the testing effort by warranting the integrity of the actual tests and to ensure unbiased reporting of the test results.”

“EPRI is accelerating deployment of a full portfolio of clean energy technologies to support a net-zero future,” said Neva Espinoza, EPRI vice president of Energy Supply and Low-Carbon Resources. “This demonstration project with Wärtsilä and WEC Energy Group is significant in showing the potential of hydrogen blending in natural gas–fired engines. The learnings from this project will be shared with the energy industry to further progress toward deep decarbonization targets.”

The 55-MW Mihm plant, operated by UMERC, entered commercial operation in late March 2019. It is one of two natural gas–fired facilities UMERC opened at that time in Michigan’s Upper Peninsula as part of the utility’s move away from coal-fired power generation. Burns & McDonnell served as the engineering, procurement, and construction contractor for both the Mihm facility and the F.D. Kuester Generating Station, located near Marquette.

The hydrogen fuel tests conducted at A.J. Mihm utilized an unmodified 18-MW Wärtsilä 50SG gas-fired reciprocating engine. Fuel blends of up to 25% hydrogen by volume were mixed with natural gas. The Wärtsilä 50SG engine continued to supply power to the grid during testing, and Wärtsilä said the 50SG served as the largest internal combustion engine ever to operate continuously on a hydrogen fuel blend—what the company called “a world-first achievement.”

Rodriguez told POWER, “This project is proof positive for Wärtsilä customers that our unmodified engines can perform as specified under real-world field conditions on hydrogen fuels. Adapting seamlessly to a new fuel that is as volatile as hydrogen is a testament to our engineering team’s design forethought, equipment robustness, construction quality, and controls versatility. These unique attributes assure customers know that they are continuing to make the best, most pragmatic purchase decisions in an ever-evolving energy world.”

Collaboration, Communication Keys to Success

Ostman told POWER that communication among the groups involved in the Mihm project was key to a successful outcome. “I came personally to very much appreciate the open and very honest conversations during the development of the project with WEC Energy Group and EPRI as well as the other key partners in the project, Burns & McDonnell Engineering and Certarus,” said Ostman.

Burns & McDonnell has participated in several utility-scale projects utilizing reciprocating engines, experience that helped during construction of the Mihm and Kuester plants in Michigan a few years ago. “The three-engine A.J. Mihm Generating Station was built in parallel with the seven-engine F.D. Kuester Generating Station in the Upper Peninsula of Michigan,” said Megan Reusser, the Hydrogen Technology manager for Burns & McDonnell, referencing the other aforementioned UMERC power plant. “In addition to the complicated logistics associated with designing, building, and commissioning these plants together, the Mihm site team had to work through heavy annual snowfall amounts in nearby areas of over 25 feet.”

Reusser said the company’s scope of work at Mihm for the hydrogen project “included the design interface with the existing plant and blending systems, coordination with the hydrogen supplier Certarus and engine manufacturer Wärtsilä, test plan development, and on-site assistance during the test burn data collection period.” Reusser, like Ostman, noted the “great collaboration” among many companies involved in the hydrogen test, including Lectrodryer—the hydrogen safety consultant—and Mostardi Platt, the emissions testing provider.

“EPRI facilitated project meetings and supported safety, design engineering, and test planning activities,” said Reusser. “EPRI also participated in the testing and led the assessment of the engine performance data analysis. A full test plan was developed and enacted, and measurements taken were used to assess the engine’s performance over a range of operating conditions when using a hydrogen-natural gas blend. Key parameters measured included electrical output, efficiency, and emissions.”

EPRI released a report earlier this year that said the group’s analysis confirmed the feasibility of blending hydrogen with natural gas for use in an existing Wärtsilä engine. The group wrote that demonstration results from the Mihm plant showed hydrogen can be safely and reliably handled and utilized in engine technology.

Compiling the Data

Wärtsilä officials told POWER that “performance of the 50SG engine was measured for the set of investigated test points, such as output power and heat rate.” In addition to this, key emissions like NOx, CO, and total hydrocarbon (THC) emissions were measured along with measurements of the gas composition of the natural gas and the concentration of hydrogen in the fuel mix (Figure 1). “As long as the engine could be tuned without limitations, the energy efficiency improved with higher hydrogen-blending ratios,” the officials said.

|

|

1. This worker is using a testing wand to collect measurements and other data as part of the hydrogen blending project at the A.J. Mihm facility. Courtesy: WEC Energy Group |

Ostman said that during the testing, “with some engine-control parameter tuning, all emissions were at par or lower when co-firing hydrogen compared to natural gas. Throughout the test, the engine was compliant with the air permit for the installation.”

Reusser said of the Mihm test: “The 18-MW reciprocating internal combustion engine unit was continually monitored to measure performance, output, and emissions data. During the testing, the capability of the Wärtsilä engine to co-fire hydrogen blends was successfully demonstrated, showing clear improvements in carbon emissions, while staying compliant with nitrogen oxide emissions. A 95% engine load was achieved with the 25% by volume hydrogen blend.”

Reusser noted that the project “was the first hydrogen power test of a utility-scale, grid-connected reciprocating engine generator in the world. Engine efficiency was not significantly impacted by hydrogen fuel blending, allowing this class of engine to maintain its higher levels of efficiency compared to simple-cycle gas turbines. Because engines in general have higher efficiencies, their relative CO2 output compared to gas turbines will also be lower, as was the case in this study.”

Ostman emphasized, “There are lessons learned when conducting testing campaigns together with customers, but I would say that the main thing was the confirmation of how uneventful these demonstrations can be with proper planning and good project partners.” Ostman added that Wärtsilä is “currently in several active customer discussions related to similar and even more long-term demonstrations.”

Ostman told POWER, “It’s good to keep in mind that the [Mihm project] presents the results from that particular engine and installation. For other power plants out there in the world, the results can be different depending on the prevailing ambient conditions as well as the condition of the plant.” Ostman noted that the Mihm test “demonstrates the viability of a first step towards lower carbon emissions, but further steps are of course later needed if we want to decarbonize the industry.”

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).