Power systems today operate in an environment where reliability and safety must be maintained despite rising loads, expanding interconnections, and increasing dependence on distributed energy resources. One of the most important technologies that supports this stability is the digital overcurrent relay. Although relays have existed for generations, the modern digital version has reshaped how engineers detect abnormal current conditions and protect equipment across both transmission and distribution networks. These relays apply complex logic, communicate with other intelligent devices, and respond with the precision necessary to isolate faults before they escalate into wider system disturbances.

A digital overcurrent relay constantly measures current and compares it with its programmed pickup values. When current reaches or exceeds a threshold, the relay determines the fault severity and decides whether to issue a trip signal to the circuit breaker. Behind this simple concept lies a layered system of protection principles that distinguishes normal variations from dangerous conditions. Instantaneous overcurrent protection responds immediately to very high fault currents, clearing severe faults before they inflict mechanical or thermal stress on equipment. Time-overcurrent protection, on the other hand, operates with a calculated delay so that devices closest to the fault can act first. This ensures selectivity within the system, allowing only the protective device nearest to the fault to interrupt the circuit while upstream devices remain in service.

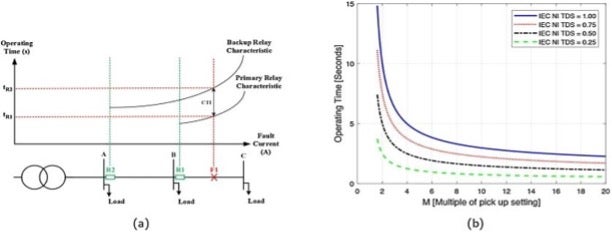

Inverse-time characteristics such as IDMT curves contribute significantly to the effectiveness of modern relays. These curves reduce the relay operating time as the fault current increases, while still maintaining a minimum time limit for stability. This relationship creates a natural coordination structure where downstream relays act quickly for local faults, and upstream relays operate only if the fault is not cleared. Protection engineers devote extensive attention to selecting curve types, setting pickup values, adjusting time dials, and calculating coordination margins. Even small variations in fault current calculations, impedance values, breaker operating times, or CT performance can influence the final settings. Developing proper coordination requires engineers to build and analyze time-current characteristic plots that visually confirm the selectivity and grading across feeders and substations.

The engineering work behind these protection schemes begins long before the relay is placed into service. Engineers model the system using specialized software and conduct short-circuit studies to determine fault levels for different fault scenarios. These studies provide the foundation for defining pickup thresholds and choosing time characteristics. Once relay settings are proposed, engineers evaluate them under normal and contingency conditions and anticipate how equipment loading, network configuration, and system growth may affect performance. After settings are programmed into the digital relay, comprehensive testing follows. This includes secondary injection to verify element pickups, end-to-end testing using communication links, and simulated fault scenarios. Digital relays generate oscillography files, event logs, and sequence of events records, which help engineers verify that each setting and logic element behaves as expected.

Communication and Automation

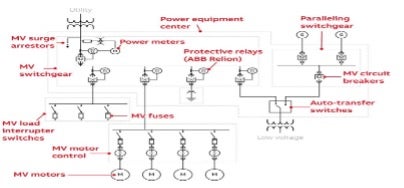

Digital overcurrent relays also strengthen communication and automation within substations. Integrated SCADA connectivity allows operators to view relay status, analyze loading conditions, review trip histories, and modify settings from a central location. Relays equipped with IEC 61850 capability can exchange information with other devices through high-speed GOOSE messaging. This supports protection interlocking, fast tripping logic, and automated control sequences without the need for extensive wiring. Such communication-enabled intelligence improves situational awareness and enables rapid, coordinated responses when faults occur.

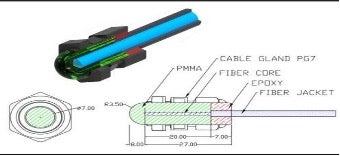

Safety is another area where digital relays provide essential benefits. Arc flash incidents present extreme hazards in electrical systems, and reducing fault clearing times is a primary method of limiting incident energy. Modern relays include arc flash detection inputs that work with optical or fiber-optic sensors to recognize light from an arc and trigger immediate tripping. This approach results in significantly faster clearing times than current-based detection alone. Zone selective interlocking also enhances safety by allowing upstream relays to restrain tripping when a downstream device identifies a fault, preserving selectivity while reducing overall arc flash energy. Digital relays further contribute to safer systems through sensitive earth-fault detection, which identifies ground faults at early stages and prevents overheating, insulation failure, and fire risk.

These modern technologies gain their true value through practical engineering application. One example is the work of the author, Sree Lakshmi Vineetha Bitragunta, a power system protection engineer. Her experience includes system modeling, relay coordination, short-circuit analysis, relay programming, and detailed testing. She has implemented digital overcurrent protection schemes that integrate inverse-time curves, instantaneous trip elements, arc flash mitigation features, and sensitive ground-fault protection. Through careful coordination across feeders and transformer protection zones, she has contributed to reducing fault clearing times and preventing outages that would otherwise disrupt customers and industrial processes.

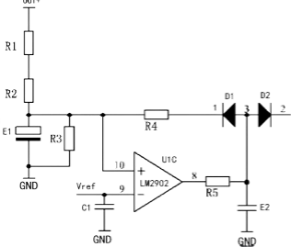

Voltage comparator circuit using LM2902. Source: Sree Lakshmi Vineetha Bitragunta

Her work also includes verifying relay behavior through testing methods such as secondary injection and end-to-end validation. By ensuring that each relay responds precisely during simulated events, she helps guarantee dependable operation once the system is energized. Her focus on integrating advanced arc flash detection and communication-based protection functions has contributed to improved reliability and safer working environments across the facilities she supports. The improvements achieved in clearing times, selectivity, and overall protection depend on the combination of accurate modeling, precise settings, and meticulous field verification carried out by engineers in roles like hers.

Responding to System Disturbances

Digital overcurrent relays have also transformed how operators and engineers respond to system disturbances. During a fault, these relays capture detailed event data, including waveform snapshots and relay element operation times. Engineers review these files to confirm whether coordination was maintained and whether the correct relay operated.

This continuous cycle of analysis and refinement improves system performance over time and aligns protection behavior with evolving system conditions. Older electromechanical devices lacked the ability to record such detailed information, making digital relays indispensable for modern diagnostic practices.

As power systems continue to evolve with higher levels of renewable generation, more complex feeder configurations, and increased automation, digital overcurrent relays will remain central to grid stability. Their programmable nature allows engineers to adapt settings without replacing hardware, and their communication capabilities support integration into increasingly intelligent substations. Their speed, accuracy, and flexibility help utilities prevent damage, maintain service continuity, and operate safely under dynamic conditions.

Through thoughtful engineering, careful coordination, and ongoing analysis, digital overcurrent relays help ensure that electrical networks remain resilient, stable, and capable of meeting the growing demands of modern society. They represent not only an improvement in protective technology but also a critical foundation for the reliability of the power system as a whole.

—Sree Lakshmi Vineetha Bitragunta is a power system protection engineer specializing in digital protection relays, arc-flash mitigation, and grid reliability. She has authored 24 research papers with 50+ citations (h-index 5). She serves as a peer reviewer for multiple international engineering journals and conferences, including the Texas Power and Energy Conference (TPEC) organized by Texas A&M University in College Station, Texas.