Power plants are engineered with precision down to the smallest detail, yet one critical variable is often considered too late in the process: water chemistry. When it’s considered early in design rather than during commissioning, facilities gain reliability, regulatory certainty, and decades of operational advantage.

Designing a modern power plant requires the precise alignment of equipment, operational strategy, environmental compliance, and long-term reliability. Yet, one factor consistently drives challenges later in the project: water chemistry. When chemistry considerations are deferred to late-stage engineering or commissioning, plants can face avoidable performance issues such as corrosion, scaling, metallurgy mismatches, permitting delays, and costly redesigns.

Integrating water chemistry early in the design process solves these challenges before they materialize (Figure 1). It enables better-informed engineering decisions, reduces operational risk, and supports long-term asset performance at a time when power plants must be more flexible, resilient, and efficient than ever.

Below are four reasons why early chemistry planning should be a foundational step in every new build or major upgrade.

Build a Smarter Water Strategy

Water chemistry directly influences nearly every engineered component of a power facility, from surface condensers and the steam cycle to cooling water infrastructure and auxiliary heat exchangers. When chemistry is evaluated alongside overall process design, heat transfer requirements, and source-water characteristics, the plant benefits from a unified, optimized strategy.

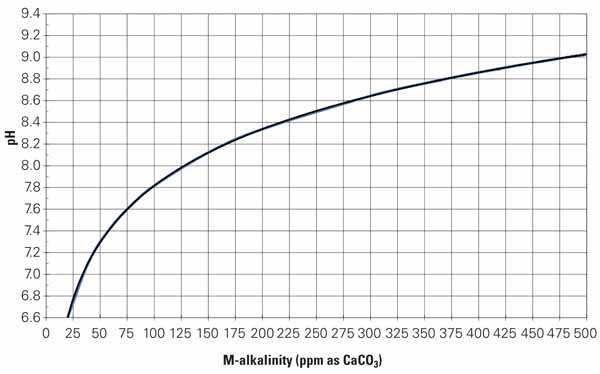

A holistic early approach helps correctly match materials of construction with expected operating envelopes. This alignment reduces corrosion and scaling risks, prolongs equipment life, and minimizes forced outages. By understanding chemical stressors upfront—such as chloride, sulfate, manganese, copper, silica, and hardness—engineers can identify limitations before they become bottlenecks.

For example, high-chloride influent may require upgraded surface-condenser metallurgy or adjusted cooling-tower cycles. Untreated copper or manganese can deposit in condenser tubing, accelerating galvanic corrosion. Ammonia in tertiary or recycle water can attack yellow metals. Even the cooling-tower basin and concrete structures can be affected: high sulfate levels may degrade certain concrete types and limit achievable cycles.

Early chemistry integration also supports strategic decision-making around cooling design (air-cooled vs. water-cooled), pretreatment configuration, and long-term operating expense (OPEX) and capital expenditure (CAPEX) tradeoffs, including whether to deploy permanent systems or long-term rental assets. With a clear understanding of water stresses, design teams can more confidently set operating envelopes, choose appropriate pre-treatment, and ensure lifecycle compatibility between water chemistry, metallurgy, and treatment programs.

To embed a holistic design into your plant from the start, consider partnering with a full-service provider that manages water from front-end engineering design (FEED) through feedstock (Figure 2). This approach ensures seamless integration of equipment design, operation, and chemistry management—enabling synergy rather than in friction between critical systems.

Design for Data and Digital Readiness

Modern power facilities increasingly depend on data-driven decision-making. Predictive analytics, condition monitoring, and artificial intelligence (AI)-enabled optimization all rely on accurate, well-structured chemistry data. Designing with chemistry in mind ensures the plant is digitally ready from day one.

Early chemical assessment informs the placement and specification of sensors necessary for long-term monitoring, particularly in areas experiencing high chemical stress or variability. Embedding data and communication infrastructure gives the plant the foundation to integrate with a digital control system (DCS) or plant information (PI) systems, enabling real-time chemical control, fleet benchmarking, and predictive maintenance.

When water-related data streams are designed into the architecture from the start, plants can automate key treatment processes, adjust programs based on scaling/corrosion indices, and respond proactively to influent variability or load changes. This readiness reduces risk, improves operational consistency, and enhances the plant’s ability to support advanced analytics over the full asset lifecycle.

Simplify Permitting

Permitting is often one of the most time-intensive aspects of launching a power project. Early consideration of water chemistry significantly improves accuracy in environmental filings, resulting in more predictable approvals and fewer last-minute redesigns.

By defining treatment chemistry, mass balances, and anticipated discharge quality early, project teams can streamline submittals for National Pollutant Discharge Elimination System (NPDES), zero liquid discharge (ZLD), or other regional permits. This upfront clarity helps avoid rework and reduces the likelihood of delays in commercial operation dates.

Chemistry planning also supports compliance with environmental, health, and safety (EH&S) requirements. Chemical storage, handling, containment, and material safety data sheet (MSDS) evaluations can be integrated directly into site design rather than added reactively. When regulators see that a project has incorporated responsible chemical management from the outset, approval processes typically proceed more smoothly.

Speed Up Commissioning

Start-up is one of the most chemistry-intensive phases of any power project. Without early planning, commissioning teams can encounter unexpected water-quality challenges, improper feed points, oversized or undersized chemical equipment, and delays in making systems water-ready.

Integrating chemistry in the design phase ensures that injection points, feed systems, and containment facilities are considered alongside process piping (Figure 3). Automation and control loops can be designed early, allowing seamless integration with the plant DCS and reducing the risk of rework.

A well-prepared commissioning plan includes expected chemical needs for flushing, passivation, cleaning, biocide treatments, and steam-cycle preparation. These steps often require higher-than-normal chemical dosing and can produce abnormal wastewater profiles—issues far easier to manage when identified early.

Early chemistry planning also supports flexible operation, an increasingly critical requirement for today’s power generators. Plants built with appropriate chemical redundancy and predefined layup procedures can better accommodate cycling, rapid ramping, and seasonal operating variability without compromising asset health or water system stability.

Chemistry Is a Design Decision, Not a Retrofit

As the power industry evolves, driven by flexible generation requirements, water scarcity, and increasingly stringent environmental expectations, water chemistry can no longer be treated as a late-stage consideration. Early integration provides a structured path for optimized design, digital readiness, predictable permitting, and reliable commissioning.

Projects that embed chemistry early gain long-term operational advantages: lower lifecycle costs, fewer unplanned outages, better asset longevity, and stronger environmental performance. In a sector where margins and megawatts matter, the most reliable facilities are those built on a complete understanding of the water they depend on—starting at day zero.

—Aquatech contributed this article.