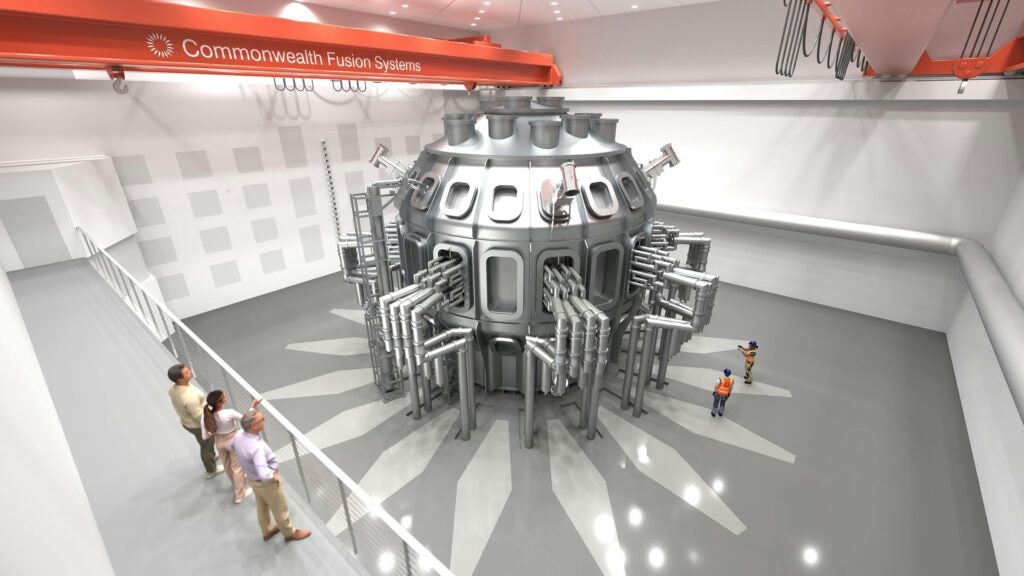

Nuclear energy company Commonwealth Fusion Systems (CFS) said it would collaborate with chipmaker NVIDIA and energy technology group Siemens to develop a digital twin of its SPARC fusion machine. The companies on January 6, in an announcement during a keynote address at the CES technology show in Las Vegas, Nevada, said their work will apply artificial intelligence (AI) and data and project management tools to accelerate commercial fusion.

The groups on Tuesday said the digital twin will leverage data from the Siemens Xcelerator portfolio of industrial software, which includes the Designcenter NX for advanced product engineering, along with Teamcenter product lifecycle management (PLM) tools. CFS uses those tools to create, catalog, and process machine designs and assemblies. The designs and assemblies can then be used in CFS’s modeling and simulation workflows, including the layering of AI-enabled tools, according to the companies.

Bob Mumgaard, CEO of CFS, talked about his company’s work during an appearance alongside Roland Busch, CEO of Siemens, and NVIDIA CEO Jensen Huang at CES. Mumgaard said CFS will use NVIDIA Omniverse libraries and OpenUSD to integrate data with classical and AI-powered physics models to create the digital twin of SPARC. The virtual replica of SPARC will provide CFS with a way to run simulations, test hypotheses, and more quickly compare the experimental results from the machine to the simulations. Officials said having the ability to rapidly analyze data and refine and improve functions will speed CFS’s efforts to commercialize fusion energy.

Technology giant Google already has agreed to buy power from the CFS power plant being planned in Virginia. CFS, founded in 2018 and spun out of the Massachusetts Institute of Technology (MIT), has raised nearly $3 billion in funding. The company raised $863 million in its latest funding round, with support from NVentures, NVIDIA’s venture capital arm.

Fusion energy has been gaining backers, including technology companies who see fusion as a way to supply power for energy-intensive data centers. Google also has supported California-based TAE Technologies, which last month merged with the Trump Media & Technology Group in a $6-billion deal.

Compress Years Into Weeks

“CFS will be able to compress years of manual experimentation into weeks of virtual optimization using the digital infrastructure developed by NVIDIA and Siemens,” said Mumgaard, who co-founded Massachusetts-based CFS. “Through this collaboration, we’re demonstrating how AI and integrated digital engineering can accelerate progress from design to grid power. This will allow us to transform how we build and operate fusion machines in the race to commercial fusion.”

Rev Lebaredian, vice president of Omniverse and Simulation Technology at NVIDIA, said, “Delivering commercial fusion demands that we simulate and solve incredibly complex physics problems. By using Siemens NX software and NVIDIA Omniverse libraries to create a high-fidelity digital twin of SPARC, CFS will be able to accelerate its engineering and shorten the timeline to clean power.”

CFS is also using Siemens’ digital tools to improve the efficiency of its manufacturing processes and operations at the company’s magnet factory in Devens, Massachusetts. Del Costy, president and managing director, Americas, for Siemens Digital Industries Software, said, “By connecting Siemens Xcelerator with NVIDIA AI visualization libraries, we’re demonstrating that end-to-end digital workflows aren’t just efficient, they’re transformative. Fusion is complex, but data doesn’t lie. When you aggregate real manufacturing intelligence, apply AI, and run thousands of scenarios, you remove guesswork and accelerate innovation. This is the future of industrial engineering.”

Manufacturing Milestone

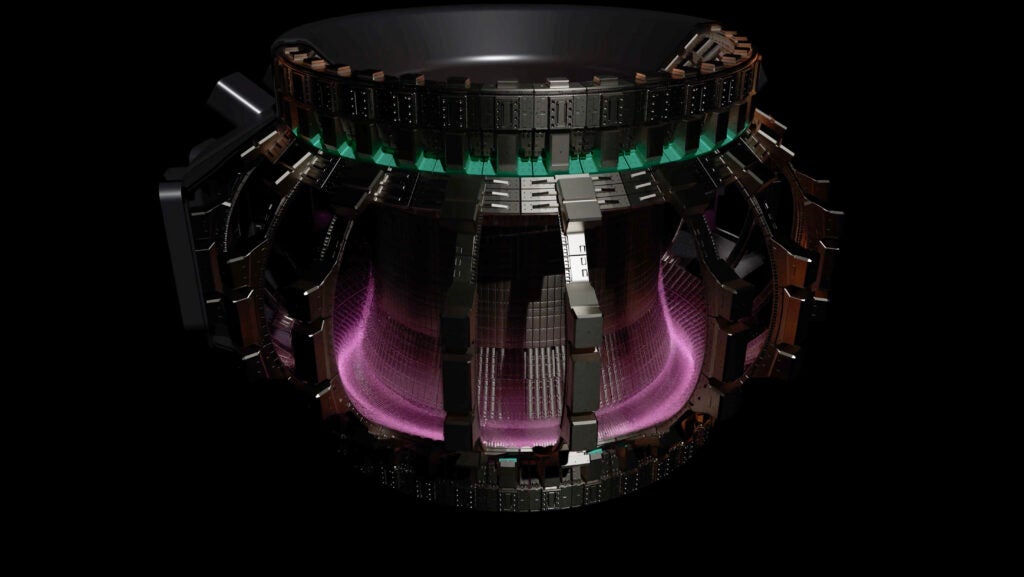

CFS in an email to POWER said that the company also Tuesday made a surprise reveal of a significant manufacturing and construction milestone, noting that the first magnet has now been installed in SPARC. The company said this is the first of 18 D-shaped toroidal field, or TF, magnets needed for the machine. CFS said that for context, the company’s breakthrough high-temperature superconducting (HTS) magnet technology “can carry high electrical currents with no losses and can better withstand the strong magnetic fields inside the tokamak.” It added, “Crucially, HTS is what lets the company create smaller, stronger magnets than was possible with last-generation superconductors. And making tokamaks more compact means fusion power becomes more commercially viable and affordable.”

The company said installation of the first magnet “is a big deal because it shows the maturity not just of this key technology but also of CFS the company,” noting the progression from ideas to prototypes, and then to initial manufacturing and full production. Mumgaard said CFS expects to install all 18 magnets needed by the end of the summer. “It’ll go bang, bang, bang throughout the first half of this year as we put together this revolutionary technology,” said Mumgaard.

—Darrell Proctor is a senior editor for POWER.

- Generation IV reactors

- advanced nuclear

- Thorium fuel cycle

- Fuel conversion

- molten salt reactor

- Experimental reactors

- Shanghai Institute of Applied Physics (SINAP)

- Idaho National Laboratory

- Chinese Academy of Sciences (CAS)

- nuclear innovation

- Clean Core Thorium Energy

- Thorizon

- ThorCon International

- Copenhagen Atomics

- nuclear research