O&M

-

O&M

Understanding Coal Power Plant Heat Rate and Efficiency

Proposed U.S. standards for reducing carbon emissions from existing coal-fired power plants rely heavily upon generation-side efficiency improvements. Fuel, operations, and plant design all affect the overall efficiency of a plant, as well as its carbon emissions. This review of the fundamentals of coal plant efficiency, frequent problems that reduce efficiency, and some solutions for […]

-

O&M

Robotic Inspections of Nuclear Power Plant Storage Tanks

Nuclear power station water storage tanks, located above ground or underground, are constructed of aluminum, stainless steel, or carbon steel. All have naturally occurring electro-chemical processes that can eventually deteriorate the metal, resulting in leaks. Defects that develop on the underside of tank floors are particularly difficult to detect and measure. The Nuclear Energy Institute […]

-

Legal & Regulatory

Best Practices for Aligning Safety Metrics, Incentives, and Performance

The Occupational Safety and Health Administration requires certain incidents to be recorded and reported, which generates a set of statistics that many companies use to gauge safety performance. However, other metrics may be better predictors. The Occupational Safety and Health Administration (OSHA) requires all employers with more than 10 employees, and whose establishments are not […]

-

O&M

Global Water Outlook for Power Generation

Water and energy are intimately linked. Water is necessary for the production, distribution, and use of energy. Energy is needed for the withdrawal and delivery of water. The two are inseparable. Several

-

Legal & Regulatory

How U.S. Power Generators Are Preparing for 2015

In mid-November, members of the POWER Generating Company Advisory Team responded via email to the following set of questions. Their comments have been edited for style. POWER: What changes in your fleet’s

-

O&M

Primer on Fuel Quality Analysis

Back in the “good old days” of the power industry, fuel was cheap, fuel supplies were fairly constant, air emissions regulations were loose, and power plant coffee was as dark as sin and worse for you

-

O&M

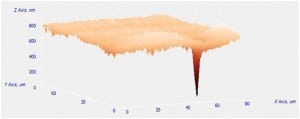

Inspecting Aberrant P91 Components for Integrity

Many utilities around the world have been discovering abnormal or aberrant P91 base and weld metal microstructures in their plants, leading to, or with a potential to lead to, early cracking and failure in

-

O&M

Wind Turbine Generator Maintenance: What to Expect and Why

Over the past few years, wind generation projects have become prominent features of the North American landscape and of the utility infrastructure. In spite of their variable production load onto the grid

-

O&M

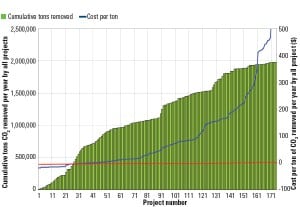

Coal-Fired Power Plant Heat Rate Improvement Options, Part 2

In recent years several EPRI projects have explored different aspects of heat rate improvements. This article, following Part 1 in the November 2014 issue of POWER , reviews results of implementing heat rate

-

O&M

Assessing and Prioritizing Structural Repairs to Material-Handling Systems

Material-handling systems at coal-fired power plants operate nearly continuously in harsh conditions for decades. Temperatures, moisture, overload conditions, and collisions from equipment can take a toll on

-

O&M

Point Level Capacitance Switch for Fly Ash Hopper Measurement

If you’re the person tasked with controlling the level of fly ash in collection hoppers, you know how difficult the application can be. What at first looks like a simple measurement quickly proves to be much more demanding in actual execution. The first problem is the environment inside the collection hoppers, which is extremely challenging […]

-

O&M

Boosting Efficiency with a Sootblowing Optimization System

Too-frequent sootblowing can damage boiler components and place a big load on plant efficiency, but not enough of it can be just as big a problem. A sootblowing optimization system can help you find the “sweet spot.” With the increasing demands placed on today’s coal-fired power plants worldwide, operators are continuously looking for the best […]

-

O&M

Coal-Fired Power Plant Heat Rate Improvement Options, Part 1

Even without regulatory considerations, there are good reasons for virtually every coal-fired power plant to improve its heat rate. The Electric Power Research Institute (EPRI) has looked at dozens of methods for improving heat rates and evaluated their applicability and costs. Part 1 of this two-part series explains the basics of heat rate improvements and […]

-

O&M

Portable Oil Analysis Tools Reduce Routine Maintenance Costs

What do a power plant, a hospital, a police station, and a remote mine have in common? They all have essential assets requiring uninterruptible power, commonly powered by an engine generator as primary or backup power. Engine generators, often termed “gensets,” combine an electrical generator and an engine. They supply electrical power where normal utility […]

-

O&M

Gaining Control with Electraulic Actuators

Plant engineers at Eskom’s Majuba Power Station in South Africa have been continuously looking for ways to improve efficiency and reliability. The six-unit, 4,000-MW, supercritical coal-fired plant was experiencing an efficiency decrease of 5% to 7%, which plant engineers determined was caused by poor performance of the actuators on their condensate level control valves (CLCVs). […]

-

O&M

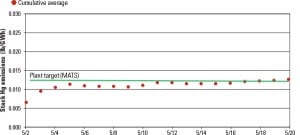

Non-Carbon Reagent Injection for MATS Compliance

The upcoming implementation of the Environmental Protection Agency’s (EPA’s) Mercury and Air Toxics Standards (MATS) is putting pressure on coal-fired power plants to develop and implement compliance

-

O&M

Proper Lubrication Practices Improve Plant Operations

Although industrial lubricants typically account for only 1% of plant operational costs (Figure 1), the lack of proper lubrication products, techniques, or applications can have a much more severe effect on

-

O&M

Prepare Your Coal Plant for Cold Weather Operations

Cold temperatures are nothing new, but extreme winter weather has been in the headlines more and more in recent years. Many of us had never heard the term “polar vortex” before last winter, but earlier

-

O&M

Prepare Your Gas Plant for Cold Weather Operations

A sustained Arctic blast composed of freezing rain, record snowfalls, and high winds hit 22 states, from Mexico to New England in early February 2011. The extreme weather severely affected the power generation

-

O&M

Prepare Your Nuclear Plant for Cold Weather Operations

During the Jan. 3–12, 2014, polar vortex that brought record-setting cold temperatures and severe winter weather to much of the U.S., nuclear plants not only survived, but thrived. According to the Nuclear

-

O&M

Quickly Boost Your Combustion Turbine Response

Twice this year, PJM flirted with blackouts when brutal winter storms (dubbed a polar vortex) struck the Eastern U.S. in January. The cold weather set a new winter peak demand record of 141,500 MW on Jan. 7

-

O&M

Two Units at Coal Power Plant Back Online Following Spring Fire

With Units 6 and 7 back in operation, Colorado Springs Utilities (CSU) has restored 80% of the generation capacity at its Martin Drake Power Plant located in downtown Colorado Springs. The plant was taken offline after sustaining significant damage during a May 5 fire. Most of the damage occurred in the area surrounding Unit 5, […]

-

O&M

Boiler Chemical Cleaning: Doing It Correctly

Like some of those tests your doctor is always after you to get, boiler chemical cleaning is something that most of us would rather not think about but that we all agree is necessary. Adding to our general discomfort with the process are new Environmental Protection Agency regulations, which make the disposal of chemical cleaning […]

-

O&M

New Disaster Preparedness Approaches for Nuclear Plants

To ensure that its nuclear plants do not meet the same fate as those damaged and destroyed by the March 2011 events at the Fukushima Daiichi plant—should they be hit by similarly severe natural disasters—Tennessee Valley Authority (TVA) is using multiple new approaches to enhance safety. First Installation of New Spent Fuel Pool Instrumentation Spent […]

-

O&M

Digital Writing Solution Allows Timely Updates to Drawings and Field Reports

Skilled maintenance and service teams inspect critical infrastructure, perform preventive maintenance, and quickly respond to issues to keep service levels high. It is critical that such teams work with as-built drawings that reflect original plans along with the cumulative changes. Armed with the current drawings, service teams can avoid surprises. The challenge is that drawings […]

-

O&M

More Strategies for Inspecting HRSGs in Two-Shift and Low-Load Service

This supplement to “Strategies for Inspecting HRSGs in Two-Shift and Low- Load Service” in the August issue includes additional discussion of the heat recovery steam generator (HRSG) Inspectors Toolkit and HRSG Inspection Guide sections of the main article plus additional photos of damage caused by rapid startups and two-shifting of units over time. More Tools […]

-

O&M

Rapid Cycling: The Human Factor

A combination of falling natural gas prices, greater integration of renewable generation, and advancing technology has meant changing roles for many plants, particularly gas turbine combined cycle plants. (See “Managing the Changing Profile of a Combined Cycle Plant” in the June 2014 issue.) The added wear and tear on plant equipment, and the changing maintenance […]

-

O&M

Strategies for Inspecting HRSGs in Two-Shift and Low-Load Service

Aheat-recovery steam generator (HRSG) is much like other power generation equipment—run it at design conditions and chances are it will run with high availability and require only routine maintenance for

-

O&M

Trackers Optimize Yield of Utility-Scale Solar Plants

The utility-scale solar market is rapidly growing in North America, representing a large area of opportunity for project and product developers alike. The market more than doubled in size between 2012 and 2013

-

O&M

Intelligent Monitoring of Distribution and Emergency Power Systems Improves Availability

Problematic power plant systems diminish availability and directly affect plant productivity and efficiency. In order to maintain availability, electrical testing and maintenance services are imperative. Two