Dominion Energy plans to build eight new natural gas-fired power plants and speed the pace of its renewable energy efforts, according to the utility’s integrated resource plan (IRP) filed with Virginia…

Coverage of every aspect of gas-fired power plant design, construction, and O&M, including combined cycles, HRSGs, cogeneration, and LNG.

Dominion Energy plans to build eight new natural gas-fired power plants and speed the pace of its renewable energy efforts, according to the utility’s integrated resource plan (IRP) filed with Virginia…

For 20 years, the technology group Wärtsilä has supported the economic development of Bangladesh through the provision of electricity generating capacity. This support is continued with the latest contract for…

The operator of the nation’s largest electrical grid on April 30 reiterated its system will remain reliable even with the retirements of substantial generation resources. But PJM Interconnection, whose system…

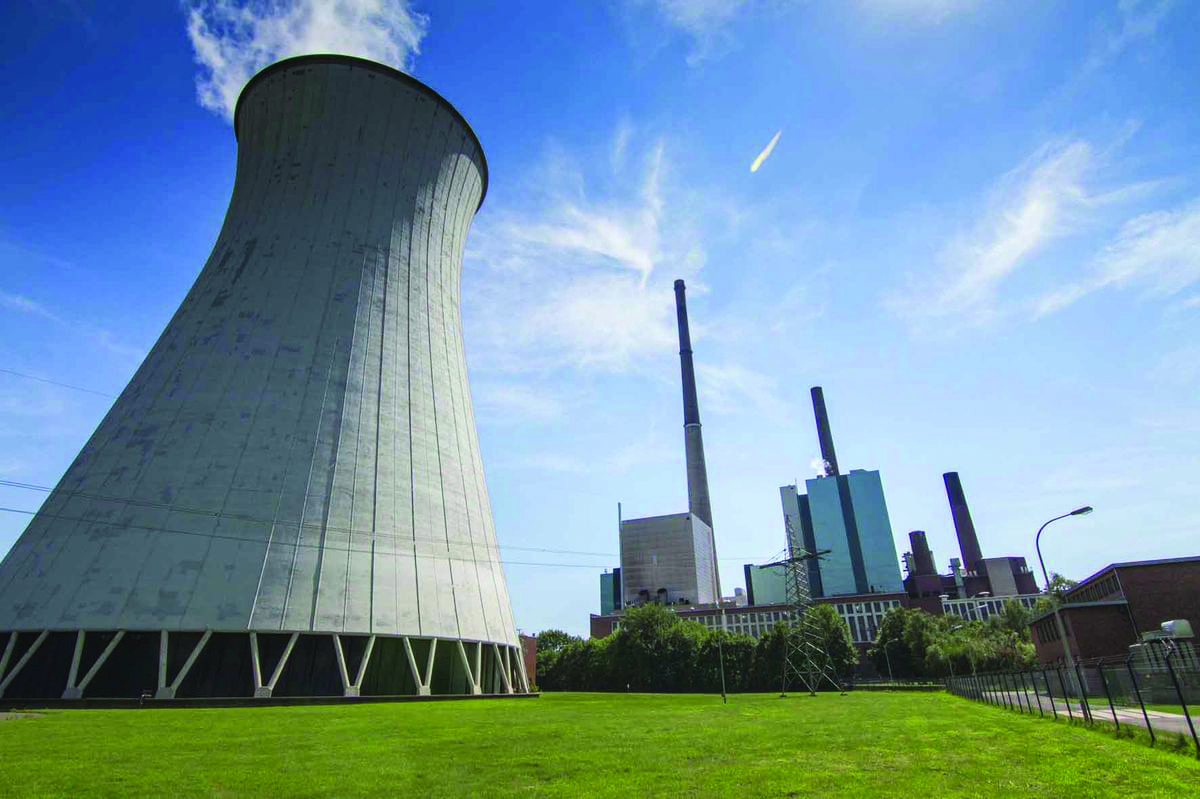

Germany’s electricity sector faced a renewed, violent shakeup in March as two of its biggest utilities, E.ON and RWE, announced a complex asset exchange that experts said points to the…

Mitsubishi Hitachi Power Systems (MHPS) in March said it would work with the Netherlands Carbon-Free Gas Power project to support the conversion of the country’s 1.32-GW Magnum gas-fired power plant…

Regulatory uncertainty, changing resources, and an industrywide drive to cut costs and boost flexibility and efficiency are among a growing list of challenges that are prompting new approaches to treat…

As water demand soars in every corner of the world amid widespread drought and water scarcity concerns, recovery and recycling of wastewater is increasingly becoming a valuable solution to alleviate…

It’s not a secret that the North American power mix is changing. Renewable energy and natural gas are picking up market share while coal-fired generation shrinks and nuclear power remains…

The traditional electricity grid is being transformed, as more businesses look to control their costs by producing their own power. A need for reliable backup power, the push for more…

A continuous emissions monitoring system (CEMS) is required in the U.S. under Environmental Protection Agency (EPA) regulations to continuously collect, record, and report emissions data. CEMS are used to monitor…