Coal

-

Coal

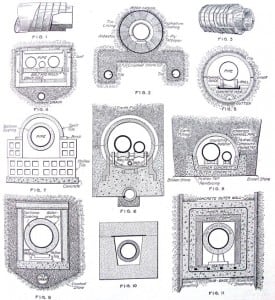

Managing air to improve combustion efficiency

The average pulverized coal–fired coal plant is more than 30 years old and has a heat rate in the neighborhood of 10,300 Btu/kWh operating with an "off-design" coal. Add a high load factor (or increased cycling service), squeezed maintenance budgets, reduced plant staff, and increased time between overhauls to meet the plant’s pro forma, and you’ve got major stress. Fortunately, there is a way to come in under your NOx budget and lower the stress. Breathe deeply and read carefully.

-

Coal

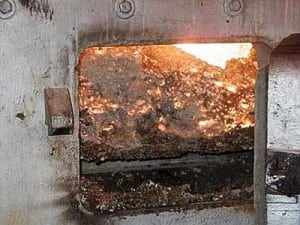

Harness detonation waves to clean boiler tubes

Air and steam sootblowers have been the power industry’s solution to the slagging and fouling of boiler convective passes caused by flyash and combustion products. Manual cleaning systems have been superseded by computers and neural nets, but the basic cleaning apparatus remained unchanged—until now. Say hello to detonation waves. They can knock those deposits loose while markedly improving boiler heat transfer efficiency.

-

Coal

Global Monitor (September 2007)

Constellation files partial COL / IAEA scrutinizes shaken Japanese nuke / Wave energy of the future? / New GE plant reigns in Spain / Solar house competition heats up / Oxygen-blown IGCC, at micro-scale / Turning corncobs into ethanol / Court blocks gas attack on coal project / New advanced energy initiatives / POWER digest

-

Coal

Speaking of Coal Power: BACT to the Future

This August, Peabody Energy’s 1,600-MW Prairie State Energy Campus project in Illinois won a major federal appeals court decision, removing the last obstacle to groundbreaking. The six-year regulatory review process ended with an unsuccessful Sierra Club challenge to the $2.9 billion project’s air permit. The decision is sure to reverberate across the nation, and I […]

-

O&M

The Coal Patrol: Mine Safety Deserves More Than Lip Service

Every step forward in underground U.S. mine safety in the 20th and 21st centuries has been on the backs of mangled and dead coal miners. That grisly observation is unassailable. Following the August tragedy at the Crandall Canyon mine in Utah that killed six miners and three would-be rescuers, the federal Mine Safety and Health […]

-

Coal

PRB Tech Notes: AmerenUE Teams with Charah and Home Depot to Market Ash for Concrete Mix

Burning Powder River Basin (PRB) coal can be a curse or a blessing, depending on your attention to the details of plant design and operations. One disadvantage of PRB coal combustion is the abundance of bottom ash and flyash generated as a by-product. Handling and properly disposing of the ash can be challenging and costly. […]

-

Coal

Coal Plant O&M: How Switching to PRB Lowered O&M Costs

Lansing Board of Water & Light (LBW&L), which has generated electricity since 1892 and steam since 1919 in mid-Michigan, primarily serves the city of Lansing’s business district and all state government buildings in the downtown area. But one of the municipal utility’s plants, Moores Park, has an additional and very important steam customer: General Motors’ […]

-

Coal

Coal Plant O&M: SmartAsh Proves Its Worth

Every day, while driving to his job at PacifiCorp Energy’s Dave Johnston plant near Glenrock, Wyoming, Cole Harris used to wonder as he neared the station how opaque Unit 3’s stack emissions would look. Until a few years ago, Unit 3 (Figure 3) had trouble staying at or below opacity limits set by the state. […]

-

O&M

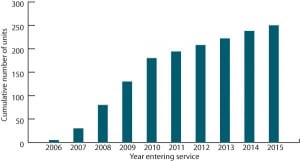

Plant Economics: The Impact of Shortages on FGD Prices

Since ratification of the Clean Air Act (CAA) in 1970, U.S. utilities have made steady efforts to install pollution control equipment to curb power plant stack emissions. The CAA Amendments of 1990 raised concerns at the time about the industry’s ability to install a large number of flue gas desulfurization (FGD) systems, or scrubbers, in […]

-

O&M

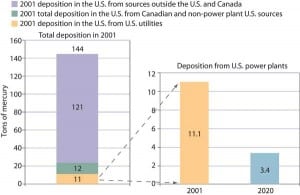

Mercury Control: Capturing Mercury in Wet Scrubbers: Part II

In Part I of this two-part report ( COAL POWER, July/August 2007, p. 22), we introduced the integrated R&D effort by the U.S. Department of Energy’s National Energy Technology Laboratory (DOE/NETL) to improve understanding of the mechanisms of mercury (Hg) capture and retention in flue gas desulfurization (FGD) systems and the fate of Hg in […]

-

Coal

The Coal Pile: Steam Blast Rocks Big Apple

This July, an underground steam pipe near Manhattan’s Grand Central Terminal ruptured and spewed a scalding brown geyser of steam and debris higher than the nearby 77-story Chrysler Building. The blast, which injured 30 people, created a 40-foot crater at street level that swallowed a tow truck. A similar explosion in 1989 killed three people. […]

-

O&M

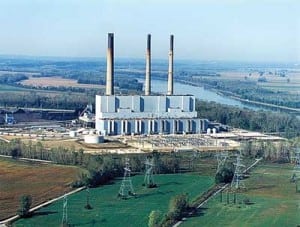

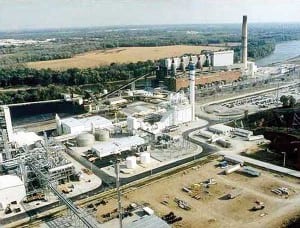

MidAmerican’s Walter Scott, Jr. Energy Center Unit 4 earns POWER’s highest honor

MidAmerican Energy Co. and its project partners are convinced that supercritical coal-firing technology’s inherently higher efficiency and lower CO2 emissions no longer come with a price: reduced reliability. Their Walter Scott, Jr. Energy Center Unit 4, the first major new supercritical plant in the U.S. in more than 15 years, is POWER’s 2007 Plant of the Year.

-

Coal

PSNH’s Northern Wood Power Project repowers coal-fired plant with new fluidized-bed combustor

The Northern Wood Power Project permanently replaced a 50-MW coal-burning boiler at Public Service of New Hampshire’s Schiller Station with a state-of-the-art fluidized-bed wood-burning boiler of the same capacity. The project, completed in December 2006, reduced emissions and expanded the local market for low-grade wood. For planning and executing the multiyear, $75 million project at no cost to its ratepayers, PSNH wins POWER’s 2007 Marmaduke Award for excellence in O&M. The award is named for Marmaduke Surfaceblow, the fictional marine engineer/plant troubleshooter par excellence.

-

Coal

Westar’s Lawrence Energy Center wins for not blinking on safety

It took Westar Energy eight years to upgrade the Lawrence Energy Center to burn Powder River Basin coal. Its zero lost-time accident record during the million-man-hour project is a testament to Westar’s commitment to workplace safety. Here’s your backstage pass to meet the PRB Coal Users’ Group 2006 Plant of the Year.

-

Coal

Navigating a carbon-constrained world

Scientific debate on the validity of global warming science continues, but the issue has yet had little impact on individuals. That impact is being negotiated in Washington, where a regulatory framework that would mandate reductions of greenhouse gases (GHGs) is taking shape. Legislative options under consideration would redefine what power plants must do-and not do-to […]

-

Coal

Dynamic classifiers improve pulverizer performance and more

Keeping coal-fired steam plants running efficiently and cleanly is a daily struggle. An article in the February 2007 issue of POWER explained that one way to improve the combustion and emissions performance of a plant is to optimize the performance of its coal pulverizers. By adding a dynamic classifier to the pulverizers, you can better control coal particle sizing and fineness—and increase pulverizer capacity to boot.

-

Coal

What’s that scrubber going to cost?

The latest benchmarking study by the EUCG examines the technology and costs of 49 flue gas desulfurization systems currently under design or construction by 12 of the nation’s largest utilities. Although the study’s detailed results are proprietary to EUCG members that participated in it, POWER was given access to the top-level findings. To get details at the plant/unit level, you’ll have to join the EUCG and participate in the study, which is ongoing.

-

Coal

The Coal Patrol: Coal to Synfuels: Deal or No Deal?

Synfuels’ political bubble has burst in Washington, but the market may step in where Congress fears to tread. When coal industry interests, in the form of the CTL Coalition, got a bill with strong federal support for coal-to-liquids technology before the Senate this spring, it appeared that the political skids were greased for some kind […]

-

O&M

Lignite Drying: New Coal-Drying Technology Promises Higher Efficiency Plus Lower Costs and Emissions

The U.S. Department of Energy (DOE) and Great River Energy are testing a new coal-drying technology that could dramatically reduce the emissions of lignite-burning power plants. The project was selected for funding during Round I of the DOE’s Clean Coal Power Initiative (CCPI), a series of competitions to demonstrate a range of promising clean-coal technologies. […]

-

Coal

Mercury Control: Capturing Mercury in Wet Scrubbers: Part I

Are you using your flue gas desulfurization (FGD) system to its highest potential? You might not be if you’re not making it do double duty. It seems that million-dollar wet scrubber you installed to rid your flue gases of sulfur dioxide also can do a decent job of capturing mercury — under the right conditions. […]

-

Coal

Speaking of Coal Power: IGCC Sticker Shock

Former Illinois Senator Everett Dirksen once observed, "A billion here and a billion there, and pretty soon you’re talking real money." The same can be said about skyrocketing estimated costs of integrated gasification combined-cycle (IGCC) plants as their designs are fleshed out. The higher price tags shouldn’t be a surprise — the more you learn […]

-

O&M

Coal Plant O&M: Smart Sootblower Tailors Cleaning to Need for It / Blending’s Impact on Coal Quality

The 1990 amendments to the Clean Air Act require coal-fired power plants to reduce their emissions of the pollutant SO2. To do so, many have switched to, or are considering switching to, Powder River Basin (PRB) coal. Unfortunately, PRB coal has a tendency to leave excessive and tenacious deposits on boiler heat-exchange surfaces. Complicating the problem, the distribution of the deposits is far from uniform.

-

O&M

PRB Tech Notes: Lawrence Energy Center Showcases Winning Plant

Lawrence Energy Center (LEC) proudly hosted about 60 representatives of the Powder River Basin Coal Users’ Group (PRBCUG) at its July 24th open house, luncheon, and plant tour. LEC was named the PRBCUG’s 2007 Plant of the Year at this year’s ELECTRIC POWER Conference and Exhibition in Chicago, May 1 – 3. Traditionally, the winning […]

-

Coal

Kimberlina: A zero-emissions demonstration plant

FutureGen may be getting the headlines, but it’s not the only superclean demonstration plant in town. In fact, you could argue that other technologies are further down the evolutionary timeline. Case in point: Clean Energy Systems’ adaptation of rocket engine technology to radically change the way fuel is burned. The result is a true zero-emissions power plant.

-

Coal

Global warming, rising costs complicate capacity additions

If little else is clear about the future of the U.S. power industry, this much is: Electricity rates are going up across the country, and will continue to. None of the esteemed panelists at the CEO session of the ELECTRIC POWER 2007 Conference & Exhibition in Chicago last month actually said those words. But much […]

-

Coal

PRB Coal Users’ Group grapples with supply chain challenges

Consumption of Powder River Basin coal continues to grow, from 28 million tons annually in the mid-1970s to what is now 400 million tons per year. Existing plants as far east as Nova Scotia burn the low-sulfur coal to comply with increasingly stringent limits on SO2 emissions, and PRB coal has become the fuel of […]

-

Coal

Climate change concerns drive projects to curb CO2

In a carbon-constrained world, CO2 capture and storage (CCS), although considered the most radical of the carbon abatement technologies (CATs), seems to be favored over combustion and steam cycle improvements alone. However, CCS is the least commercially developed of the CAT options; at present, there are only field prototypes for its various forms. Nonetheless, most […]

-

Coal

Global Monitor (June 2007)

Siemens, E.ON to test world’s largest GTG / Midwest to add 76-MW peaker in Kansas / Tapping the sun near Phoenix / Georgia Tech developing 3-D PV nanocells / Wind farms with hydrogen backup? / BNSF , union come to terms / IPL to buy 200-MW wind project / India to improve environmental monitoring / POWER digest

-

Coal

Global Monitor (May 2007)

World’s largest PV plant now in Portugal; latan 2 construction may resume; Allegheny to scrub Fort Martin plant; TVA will clean up big Dutch CC plant; Connecticut blesses six fuel cell projects; DOE approves IGCC plant in Florida; FERC relicenses Osage hydro plant; A nanotech perpetual motion machine?; POWER digest