Siemens, E.ON to test world’s largest GTG

Siemens Power Generation (SPG) last month loaded the world’s largest, most powerful gas turbine-generator (GTG) onto a barge on the European inland waterway system for shipment to a test facility in Bavaria.

Shipment by barge, and then on a low-rise loader, was scheduled to take 20 days. The factory-assembled generating package—Siemens’ 340-MW SGT5-8000H (Figure 1)—is 40 feet long and 15 feet high and weighs over 440 metric tons.

1. Big Bubba to Bavaria. Last month, this giant 340-MW gas turbine-generator took a ride, by water and land, from Berlin to an E.ON testing facility in Bavaria. In combined-cycle operation, it is expected to generate a whopping 530 MW. Courtesy: Siemens Power Generation

Siemens (www.pg.siemens.com) and the German utility E.ON are still building the test facility in Bavaria. According to Siemens, the new gas turbine will "set benchmarks in terms of output, efficiency, life-cycle costs, emissions, and operational flexibility." The company says the unit has the horsepower of a fleet of 1,100 Porsche 911 sports cars or 13 jumbo-jet engines. Following testing in simple-cycle operation, it will be tested in combined-cycle mode, in concert with heat-recovery steam generators.

Siemens says it expects the unit’s capacity and thermal efficiency ratings in combined-cycle mode to be 530 MW and 60%, respectively. The latter would beat the previous record by 2%, sufficient to lower the turbine’s annual CO2 emissions by 40,000 metric tons.

Wolf-Dietrich Kreuger, head of SPG’s gas turbine operations, said, "The output of this turbine is sufficient to provide electricity for the entire population of a city the size of Hamburg." Siemens said it is investing $740 million in the new unit, whose first firing is set for November, with commercial operation planned in 2011.

Siemens notes that a machine such as this involves a classic case of "heavy mechanical engineering and ultramodern manufacturing technology. Miniscule parts and parts weighing several tons—more than 7,000 individual parts in all—are assembled using the most advanced methods as precise as a watchmaker’s."

SPG also reports it has received an order from South Korea for major components for a 550-MW combined-cycle plant in Inchon, near Seoul. The state-owned Korea Midland Power Co. is buying two SGT6-4000F gas turbines, one SST6-5000 steam turbine, and three generators, together worth about $180 million. The Inchon plant is scheduled to go commercial in the summer of 2009.

In a related development, Siemens says it also will supply a $13.5 million combined heat and power (CHP) plant to Belarus. The contract calls for two SGT-300 steam turbines, two heat-recovery boilers, and associated balance-of-plant items.

SPG calls the SGT-300 cogeneration unit "a new concept. It is a modularized small [CHP] plant which delivers 7.5 MW of electrical power and 19 tons/hr of process steam." According to the company, "The overall efficiency of the SSC-300 plant to be delivered is 90.3%, significantly higher than current levels."

Midwest to add 76-MW peaker in Kansas

Finland’s Wärtsilä Corp. will deliver 76 MW of gas-fired, internal combustion generating capacity to Midwest Energy Inc. for its Goodman Energy Center in Hays, Kansas.

The Goodman peaking facility (Figure 2), consisting of nine 8.4-MW Wärtsilä 20V34SG gas-fired engines, will add capacity, ancillary services, and black-start capability to the generation and transmission co-op’s system, which has a demand of about 325 MW. Earlier, Midwest chose Burns & McDonnell as the engineering, procurement, and construction (EPC) contractor of the $30 million project.

2. Peaking power plus. An artist’s rendering of the lineup of the nine 8.4-MW Wärtsilä gas-fired engines that will provide Midwest Energy, a generation and transmission cooperative in Kansas, with quick-start peaking capacity. Courtesy: Midwest Energy

In a press release, Wärtsilä (www.wartsila.com) said it expects the plant to begin producing power in time for the summer 2008 peaking season, with full commercial operation planned for that September. Selective catalytic reduction systems will be added to the engines to reduce their NOx emissions.

Wärtsilä calls its gas-fired diesel engines "a competitive alternative to gas turbines," in part because they can "operate efficiently at low loads. This feature increases the number of megawatts of ‘spinning reserve’ available to the customer, thereby increasing the value of the plant." Another plus is the engines’ ability to be ramped to 25% of full output in two minutes, and to full load in less than 10 minutes; such speed provides fast response to varying grid conditions. Finally, says Wärtsilä, the units use closed-loop cooling, eliminating the need for a process water supply and wastewater treatment.

According to Burns & McDonnell (www .burnsmcd.com), a 2006 request for proposals for the new generation garnered 14 offers of baseload, intermediate, and peaking capacity from nine different vendors. Wärtsilä’s bid, said the EPC, represented "the lowest-cost option for peaking capacity."

Earnie Lehman, Midwest’s general manager, said in a press release that the Goodman Energy Center "provides a clean, cost-effective way to meet the peak energy demands of our customers, and will improve service reliability. The [peaker addition] will provide an efficient resource with extremely low emissions and negligible water consumption." Named for Jack Goodman—Lehman’s predecessor from 1951 to 1992—the plant, on the western edge of the Great Plains, sits at an elevation of 2,150 feet, so it experiences both bitterly cold and brutally hot temperatures.

Frank Donnelly, Wärtsilä’s VP for North America, said, "this power plant will be our largest in the U.S. east of Colorado, and represents our fourth big American order in the past nine months."

Tapping the sun near Phoenix

An Arizona land developer is promoting the idea of a standard photovoltaic (PV) component for a series of high-tech townhouses it hopes to build.

Salt River Project (SRP), the federally owned and Phoenix-based public power district, is partnering with Modus Development LLC to build PV-enabled homes in a Scottsdale subdivision. Each of the nine residences in an "array development" (Figure 3) will feature a grid-connected, 2-kV system.

3. Desert yuppies go green, with help. These garden apartments planned for upscale Scottsdale, Ariz., would use rooftop photovoltaic panels to meet 2 kV of their electricity demand. The PV installations are eligible for state and federal tax credits and a Salt River Project subsidy of 40% of their cost. Courtesy: Salt River Project

Modus (www.modusdev.com), whose specialties are green buildings and infill projects, has hired American Solar Electric (www.americanpv.com), a power systems engineering and contracting firm, to provide the systems. The townhouses will be eligible for a big 40% subsidy on system capital and installation costs under SRP’s "Earth Wise Solar Energy" incentive program. The home buyers can also apply for state and federal tax credits for PV installations.

According to SRP, the nine home systems in an array development should together generate 28,800 kWh of electricity annually. Generating that power by conventional combustion would release 15 tons of CO2 into the atmosphere. Lori Singleton, SRP’s environmental initiatives manager, said, "As more homebuyers realize the benefits of ‘going green’ in this way under our program, we expect to see more of them insisting on harnessing the power of the Arizona sun."

The townhouses will meet the standards of the Leadership in Energy and Environmental Design (LEED) managed by the U.S. Green Building Council. SRP explains that LEED is the "nationally accepted benchmark for the design, construction, and operation of high-performance green buildings." The Modus project will be the first residential LEED-certified project in the Valley of the Sun.

Ed Gorman, president of Modus Development, said, "LEED certification is the first step in reducing the impact on the environment and lowering energy consumption. By adding solar panels to the rooftops of every home, we create homes that are both architecturally unique and cost very little to operate."

According to SRP, the development will be complete and the panels installed within 12 months.

Georgia Tech developing 3-D PV nanocells

Researchers at Georgia Institute of Technology in Atlanta are working on unique, three-dimensional photovoltaic cells, based on carbon nanotubes, that are said to be able to capture nearly all of the light that strikes them. The work could lead to higher-efficiency PV systems that are also smaller, lighter, and less complex.

The experimental solar cells capture photons in arrays of tiny tower structures that look like high-rise buildings on a city block. The researchers described the design in the March issue of the journal JOM, published by the Minerals, Metals, and Materials Society.

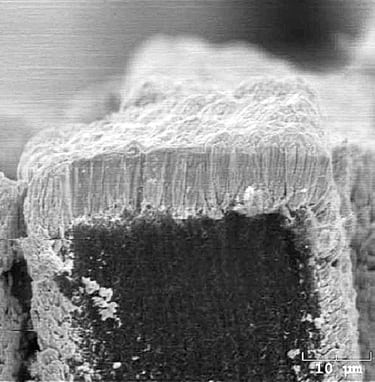

Light is trapped between the tower structures, which are about 100 microns tall, 40 x 40 microns square, and 10 microns apart (Figure 4). The structures contain millions of vertically aligned carbon nanotubes. Georgia Tech, in a news release, notes that conventional flat solar cells "reflect a significant portion of the light that strikes them, reducing the amount of energy they absorb.

4. Tiny towers of power. Georgia Tech researchers say carbon nanotube photovoltaic arrays could revolutionize methods of converting sunlight into electricity. In particular, much higher conversion efficiencies could be in the cards. Courtesy: Georgia Institute of Technology

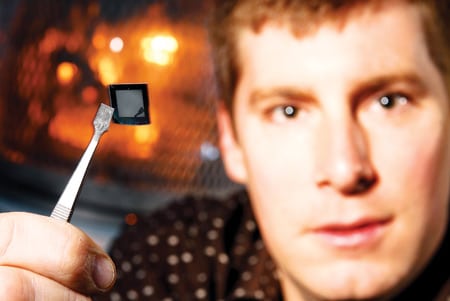

Because the nanotube structures trap light entering them at many different angles, they remain efficient even when the sun isn’t directly overhead. That property would be a boon to solar-powered spacecraft because it would obviate the need for heavy and complex mechanical aiming systems to maintain orthogonality with the sun. According to Jud Ready (Figure 5), a senior research engineer in Georgia Tech’s Electro-Optical System Laboratory, "The efficiency of our cells actually increases as the sun moves away from the perpendicular."

5. Funny glasses not required. Senior research engineer Jud Ready holds an experimental photovoltaic cell based on 3-D carbon nanotube structures. A big plus of its internal, 3-D structure: Current is produced by light entering from all directions, not just perpendicular to the cell. Courtesy: Georgia Institute of Technology

Georgia Tech also notes that conventional flat PV cells need a coating thick enough to capture photons, which then liberate electrons from the PV materials, generating a current. But that approach causes a problem: Each mobile electron leaves behind a "hole" in the atomic matrix of the coating, said the university. "The longer it takes electrons to exit the PV material, the more likely it is that they will recombine with a hole—reducing the current level."

Because the 3-D cells absorb more of the photons, they can have thinner coatings, allowing electrons to exit faster. This boosts the "quantum efficiency," the rate at which absorbed photons are converted to electrons. "Our goal is to harvest every last photon that is available to our cells," said Ready. "By capturing more of the light in our 3-D structures, we can use much smaller photovoltaic arrays."

According to Georgia Tech, fabrication of the cells begins with a silicon wafer that also serves as the solar cell’s bottom junction. The researchers first use photolithography to create a pattern on the wafer. The patterned wafer then gets cooked in a furnace at more than 1,400F. In the next-to-last step of the process, hydrocarbon gases are pushed into the furnace, where carbon and hydrogen are separated. Finally, using chemical vapor deposition, the carbon is grown into multi-walled nanotubes on the wafer.

Once the carbon nanotubes are in place, researchers use molecular beam expitaxy to coat them with cadmium telluride and cadmium sulfide, which serve as the PV cell’s "p-type" and "n-type" layers. The final, top layer is a thin coating of indium tin oxide, a clear conducting material, which serves as the cell’s top electrode.

Georgia Tech acknowledges that the new cells face several hurdles before they can be commercially produced. Ready said, "we have demonstrated that we can extract electrons using this approach. Now we need to get a good baseline to see how we compare to existing materials, how to optimize the processes, and what’s needed to advance the technology."

Wind farms with hydrogen backup?

Wind farms are the fastest-growing source of power generation in the U.S. But their biggest problem is intermittent output: When the wind stops, the farms’ production (and their owners’ revenues) go to zero. If wind-generated electricity could be stored, it would be possible to even out wind farms’ supply and better match it to varying demand.

Hydrogen Energy Center Inc. (HEC, www.hydrogenenginecenter.com)—based in Algona, Iowa, with an office in Toronto—says it has found a way around the problem. It has devised, and demonstrated, a system (Figure 6) that uses wind power to generate hydrogen (which can be stored) and then use the hydrogen to generate electricity. The company calls its process "Oxx Power 4+1."

6. Hydrogen economy. A maker of fuel-flexible internal combustion engines is touting a scheme for making the output of wind farms less intermittent. It says it has developed and demonstrated the technology needed to use excess wind power to generate hydrogen by electrolysis of water. The stored energy in the hydrogen could then fuel its engines to produce power for the grid when the wind stops blowing. Courtesy: Hydrogen Energy Center Inc.

According to HEC, when it’s windy enough that not all of a wind farm’s output is needed by the grid, the excess can be used to produce hydrogen by conventional electrolysis—the breakup of water (H2O) into H2 and O2. The hydrogen then could be burned in an internal combustion engine to produce electricity for the grid later, when the wind stops.

HEC makes a variety of "Oxx Power" internal combustion engines that can be fueled by natural gas, industrial gases, gasoline, or by hydrogen produced by chemical plants.

According to a company press release, "by integrating Oxx Power generator systems with wind-sourced power, [generating companies] can bring on-line a sustainable solution that extends the capacity and value of wind energy and reduces their dependence on petroleum and gas-burning technology." HEC recently hosted a demonstration of the technology, which it says will be placed in service as part of a wind farm in Newfoundland, Canada.

Ted Hollinger, HEC’s CEO, added, "The deployment of our near zero-emissions, hydrogen-fueled 4+1 power generation system is an important step toward the implementation of large-scale development of reliable renewable energy solutions."

A decade ago, Bonneville Power Administration looked into tapping its plentiful hydro resources to generate hydrogen during off-peak times. A study found that the concept was uneconomical, but it was based on price and cost assumptions that may not be realistic today.

BNSF, union come to terms

BNSF Railway Co.—a major shipper of Powder River Basin (PRB) coal to U.S. power plants—and the Brotherhood of Locomotive Engineers and Trainmen (BLET) have agreed in principle to a BNSF-specific labor contract to augment the national agreement between the brotherhood and the nation’s major railroads. The separate deal still must be ratified by BNSF workers.

The deal would provide increased profit sharing and minimize loss of union jobs as train control technology becomes more automated. It also would improve the workers’ pay, health, and welfare standards and meal allowances.

Stephen D. Speagle, BLET vice president, said the new deal "reflects BNSF’s unique position in the railroad industry and will enable BNSF locomotive engineers to participate fully in the railroad’s long-term growth." John Fleps, BNSF’s labor relations chief, added, "the agreement demonstrates in the plainest way the good that comes when labor leaders and management work hard together to solve the large issues which face the company and our employees."

BLET is a division of the rail conference of the International Brotherhood of Teamsters. Its predecessor union, the Brotherhood of Locomotive Engineers, was the oldest labor union in the U.S. and North America’s oldest rail labor union. It was founded in 1863 as the Brotherhood of the Footboard, and its name was changed to the Brotherhood of Locomotive Engineers a year later. BLET and the Teamsters merged in 2004, and the rail union became the BLET.

BNSF, based in Fort Worth, Texas, has a rail network of about 32,000 route miles in 28 states and two Canadian provinces. The low-sulfur PRB coal it hauls generates about 10% of the electricity generated in the U.S. (Figure 7).

7. Back on track. The Brotherhood of Locomotive Engineers and Trainmen (a division of the International Brotherhood of Teamsters) and BNSF Railway Co. have reached a company-specific labor deal that will ensure continued deliveries of Powder River Basin coal to power plants nationwide. Courtesy: BNSF

IPL to buy 200-MW wind project

Alliant Energy Corp., a subsidiary of Interstate Power and Light Co. (IPL), is negotiating with Clipper Windpower Inc. to buy the Eclipse wind farm the latter is planning to build in western Iowa.

The Eclipse plant, near Adair, Iowa, is being designed to have a maximum capacity of 200 MW. In a press release, IPL said it plans to file for approval of the transfer with the Iowa Utilities Board this summer. If the regulator gives the go-ahead, IPL would begin installing the farm’s first 100 MW of turbines in 2009.

IPL, based in Cedar Rapids, Iowa, would still use Clipper’s Liberty series turbines. Rated at 2.5 MW, they are the largest wind turbines built in the U.S. Their key mechanical equipment is assembled at Clipper’s 215,000-square-foot factory in Cedar Rapids. Clipper (www .clipperwind.com) is headquartered in Carpinteria, Calif.

IPL President Tom Aller said the prospective deal exemplifies the utility’s support of the state’s economy "through the purchase of products that are assembled right here in Iowa. Clipper Windpower is a great company to have here in the state, and it is a key participant in our state’s growing renewable energy economy." Clipper’s CEO, James G.P. Dehlsen, added, "If its full capacity of 200 MW is realized, the Eclipse project would become Iowa’s largest wind farm."

Alliant Energy (www.alliantenergy.com), based in Madison, Wis., already buys more than 300 MW of wind power from 15 wind farms (Figure 8). "We continue to seek ways to reduce the environmental footprint of our generating fleet," said Kim Zuhlke, the company’s VP for new energy resources. "Developing this wind site, using some of the most efficient and reliable wind turbines available, would represent a leap forward toward that goal."

8. Mooving up in capacity. Alliant Energy already buys 300 MW of wind power from independent wind farms in the Midwest like this one. If it receives approval to buy a proposed farm from turbine maker Clipper Windpower, Alliant will have up to 200 MW of capacity under its control. Clearly, a plant that big would reduce the utility’s total greenhouse gas emissions enough to offset the methane emissions of the cows. Courtesy: Alliant Energy

India to improve environmental monitoring

Understanding global climate change obviously requires gathering temperature data worldwide. But in key regions, such as the Indian subcontinent and Africa, not enough temperature data is being collected.

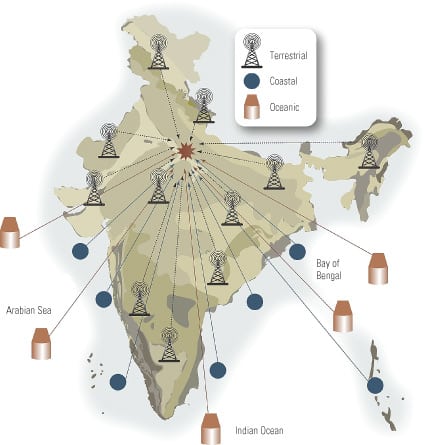

In a recent issue of Science magazine, a group of 34 Indian and U.S. researchers proposed building a system that would improve and integrate temperature monitoring across India and the Indian Ocean. Called Indoflux, the system would locate monitoring stations on land, coast, and ocean (Figure 9). The data would be shared internationally to help international science programs get a better idea of current and future environmental changes in the region. For example, it is known that the surface of Indian Ocean has warmed considerably more than that of other oceans over the past 50 years. The rise in ocean temperatures could change the onset, duration, and rainfall of the annual subcontinental monsoon on which agriculture depends.

9. India proposes monitoring network. The placement of monitoring stations in this drawing of the proposed Indoflux monitoring network reflects different climatic, vegetation, and land-use areas. Courtesy: American Association for the Advancement of Science

India’s Department of Science and Technology is backing the Indoflux proposal with a promised grant of $50 million over the next five years. According to the article in Science, "with the data generated, the scientific community can deliver the necessary scientific foundation for the development of long-term, defensible government policies to tackle environmental change and to meet our obligations under international accords. The data will support economic and strategic cooperation and collective actions internationally."

The researchers intend for Indoflux to fill in one of the big blank spots in the international monitoring system, called Fluxnet. It is a global collection of more than 300 micrometeorological terrestrial-flux research sites that monitor changes in CO2, water vapor, and energy.

POWER digest

News items of interest to power industry professionals.

GE dominates U.S. wind power industry. Last year, GE Energy was far and away the leading provider of technology and services to the U.S. wind industry. For example, the company’s wind turbines racked up a 45% share of new projects totaling 2,400 MW of capacity. That’s remarkable, considering that GE didn’t enter the wind power business until 2002.

The American Wind Energy Association says that U.S. wind power capacity increased by 27% in 2006, and the trade group projects a further rise of 26% this year.

GE says that in 2006 it supplied 764 of its 1.5-MW wind turbines to U.S. project developers. Victor Abate, the company’s VP in charge of renewables, said, "We are confident that wind power—and abundant, domestic, and zero-carbon emissions resources—will be an integral part of the U.S. energy mix throughout the 21st century."

Conoco calls for carbon caps. In April, ConocoPhillips became the first major U.S. oil company to call for a cap-and-trade program to control carbon dioxide emissions, as it joined the U.S. Climate Action Partnership.

James Mulva, Conoco’s CEO, said, "We believe the science is quite compelling that climate change is caused by human activity and the substantial use of fossil fuels." Rival ExxonMobil is considering supporting federal climate change legislation but hasn’t yet committed to do so. A company spokesman told The Wall Street Journal, "The devil’s in the details." Those details haven’t yet fully emerged, as witnessed by the multiple approaches to a cap-and-trade program circulating in Congress.

The only other oil major in the Climate Action Partnership is BP, which went by the name British Petroleum until recently resigned CEO John Browne tried to rebrand the abbreviation "beyond petroleum."

Conoco’s move comes as gasoline prices are approaching record adjusted-for-inflation levels in the U.S. and Washington is warning of extreme penalties for oil companies engaging in price gouging. Even President Bush has climbed—at least with one foot—onto the climate change bandwagon. He announced in mid-May that he wants the U.S. Environmental Protection Agency to develop a regulatory regime to reduce the use of fossil fuels by cars and trucks. As part of a so-called "20 in 10" plan, the regime would seek to reduce America’s consumption of gasoline by 20% within 10 years.

Regulating vehicles is far easier than reducing greenhouse gas emissions from power plants, something known by the administration, the oil industry, and the power industry. That’s why attention so far is mostly focused on cars, while the auto industry appears unsure of how to react.

DOE cashes $39.2 million synfuels check. This May, U.S. taxpayers got a check for that amount from Dakota Gasification Co. as the result of an old agreement to share revenues from the sale of synthetic natural gas made from coal at the Great Plains Synfuels Plant near Beulah, N.D.

The Great Plains plant is the only commercial-scale U.S. synfuels project to have produced gas from coal (although there are projects, which many analysts consider bogus, to upgrade coal and take advantage of federal tax credits for synfuel production). In the early 1980s, the U.S. Department of Energy guaranteed a $1.5 billion loan to the original developers of the Great Plains project, which uses the Lurgi technology that South Africa has used for decades to meet all of its diesel fuel needs from domestic coal resources. When the original developers defaulted on the loan in 1985, the DOE took over the plant.

The federal agency operated the plant until 1988 and then sold it through a bidding process won by Dakota Gasification, a subsidiary of Basin Electric Power Cooperative. The sale included provisions for revenue sharing so that the DOE could recoup the loan. The latest payment brings to $285 million the total paid back to the government.

Since 2000, CO2 from the Great Plains plant has been pumped through a 205-mile pipeline to an oil field in Saskatchewan, Canada, where it is used to enhance oil recovery.