Flamanville 3 synchronized to the French grid in December 2024 after a prolonged, hard-fought build—an achievement that reflects years of technical recovery, regulatory rigor, and lessons now shaping France’s EPR2 program.

On Dec. 21, 2024, at 11:48 a.m. local time, Flamanville 3 synchronized to France’s national grid, bringing online the country’s first new reactor in 25 years. The European Pressurized Reactor (EPR), with a net capacity of 1,630 MWe, is now the most powerful nuclear unit in the French fleet and is projected to deliver roughly 13 TWh of electricity annually. Yet, the milestone arrived more than 12 years later than planned and with a cost that spiraled more than fourfold, from the original €3.3 billion estimate to at least €13.2 billion, with the French Court of Auditors placing the full project’s price, including financing, near €23.7 billion.

POWER’s Top Plant award rests on the project’s resolve and engineering persistence. While Flamanville 3 was launched in 2007, envisioning a 54-month schedule, the project unfolded over 17 years as French utility giant EDF, its suppliers, and France’s Nuclear Safety Authority (ASN) confronted issues that revealed how much nuclear construction expertise had faded since the country’s last wave of builds. Pressure-vessel anomalies, break-preclusion weld deviations, and documentation gaps repeatedly slowed progress. But each setback forced deeper quality control and gradual rebuilding of industrial capability that France will rely on as it rolls out the next generation of EPR2 reactors.

“The coupling of the Flamanville EPR is a historical moment for the entire nuclear sector,” EDF Chairman Luc Rémont said when the reactor first synchronized to the grid. “I would like to salute all the teams who have met the challenges encountered during this project with the greatest tenacity, without ever compromising on safety.”

Building a Generation III Behemoth

For crucial context, Flamanville 3 is the fourth EPR to enter service worldwide, following the twin units at Taishan in China (completed in 2019) and Olkiluoto 3 in Finland (completed in 2023), projects that also won POWER’s recognition, but which faced similar construction headwinds. In all respects, France’s first EPR, perhaps carries greater weight. It is the lead installation for President Emmanuel Macron’s 2022 nuclear expansion program, which calls for six new EPR2 units with an option for eight more to support energy sovereignty and a 2050 carbon-neutral electricity system. As EDF notes in French press materials, Flamanville 3 serves as a tête de série—the reference against which future builds will standardize. Effectively, Flamanville 3 has served as the country’s test of whether a dormant nuclear construction ecosystem can be rebuilt.

The reactor is a four-loop pressurized water reactor (PWR) rated at 4,300 MWth and 1,630 MWe net, substantially larger than the standardized 900-MW and 1,300-MW PWRs that have formed the backbone of France’s fleet since the 1970s and 1980s. France operates 56 reactors across 18 sites, generating about 62% of the nation’s electricity. Those reactors, built in three waves between 1977 and 1999, achieved construction times as short as five to seven years during peak deployment. Flamanville 3, the first expansion in a quarter-century, is the first deployment of Generation III+ EPR technology on French soil.

The EPR design incorporates Generation III+ safety architecture: four independent emergency cooling trains provide 300% redundancy for decay-heat removal. The double-layer reinforced concrete containment—2.6 meters of combined thickness—is engineered to withstand aircraft crash scenarios and severe-accident internal pressures. A core catcher beneath the vessel retains and cools molten corium in the event of core damage.

Perhaps distinctly, Flamanville 3 uses Framatome’s TELEPERM XS digital platform for reactor protection and safety-class instrumentation and control, enabling automated responses to abnormal transients. On the turbine island, an Arabelle steam turbine rated at 1,750 MWe gross—among the largest ever manufactured—relies on 1.75-meter last-stage blades and a 155-square-meter low-pressure exhaust to push thermal-cycle efficiency greater than 38%.

A Long, Carefully Watched Build

Construction began in late 2007 on the Normandy coast, adjacent to two 1,300-MW units operating since the mid-1980s. EDF served as project owner and architect-engineer, Framatome provided the nuclear steam supply system, and Bouygues Travaux Publics executed civil works—placing 400,000 cubic meters of concrete and assembling 50,000 tonnes of reinforcing steel. At peak, the site mobilized roughly 2,800 workers from more than 50 nationalities; about 60% were recruited locally through a rolling bus de l’emploi training initiative designed to rebuild nuclear craft skills.

France’s ASN conducted hundreds of inspections spanning construction, pre-operation, and commissioning. Major commissioning steps—primary heat-up, divergence, 25% power, 80% power—required specific authorization. In 2024 alone, Unit 3 underwent 26 ASN inspections, including six unannounced, along with 10 full-scale emergency exercises.

|

|

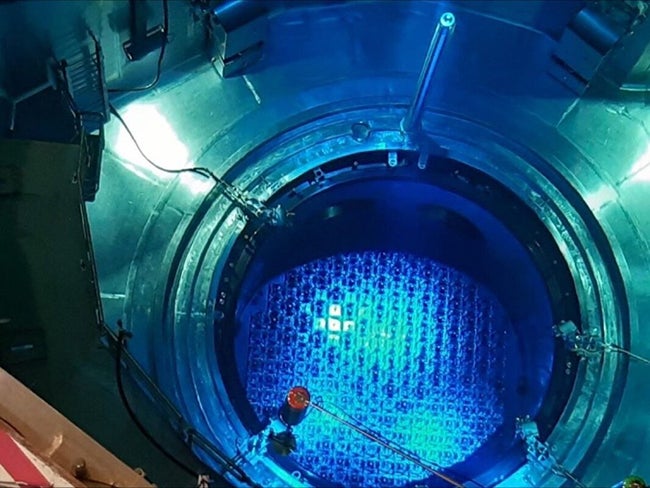

1. Flamanville 3’s EPR core contains 241 fuel assemblies, each about five meters tall and weighing roughly 800 kilograms, with annual fuel use of about 32 metric tons of uranium oxide enriched to 3–5% uranium-235. Designed for thermal efficiency of 37%, the reactor has a 60-year operating life and a target capacity factor of 91%. Courtesy: EDF |

Technical Crises and Recovery

Prominently, the project suffered two defining technical crises. In 2015, metallurgical testing revealed carbon-segregation anomalies in the reactor pressure vessel’s lower head and closure head—zones with carbon concentrations up to 0.30%, above the 0.22% limit. ASN, its technical support organization IRSN, and France’s Advisory Committee for Nuclear Pressure Equipment undertook a multiyear review. In 2017, ASN authorized operation with the as-fabricated head under strict in-service inspection, requiring replacement during an early operating cycle.

Perhaps more consequential was the 2018 discovery of quality deviations in main steam relief and “break-preclusion” piping. EDF’s pre-operational checks uncovered noncompliant weld profiles across 50- to 95-cm-diameter piping with 4–5-cm wall thickness. ASN’s examinations exposed gaps in welding proficiency, documentation, and contractor oversight. Ultimately, 53 welds were fully redone, and roughly 20 others reworked as precaution. Eight welds in tight containment-penetration galleries required a specialized robotic repair system. The campaign added roughly three years and about €1.5 billion.

The anomalies exposed systemic gaps in a supply chain that had been dormant for more than two decades. Experienced welders, pipefitters, and quality-assurance specialists had retired or migrated to other industries. ASN and independent reviewers noted insufficient detailed studies, incorrect technical references, and lost “learning by doing.” EDF’s response included retraining programs, expanded mock-up facilities, and the creation of Cotentin’s dedicated welding school, HEFAÏS.

Commissioning proceeded once ASN issued authorization on May 7, 2024. Fuel loading concluded on May 15 with 241 assemblies transferred underwater. Hot functional testing pushed the primary system to roughly 303C and 155 bar. First criticality occurred Sept. 3, 2024, at 3:54 p.m.—the first sustained chain reaction in a new French reactor in more than two decades. Grid connection followed on Dec. 21, 2024, at 11:48 a.m.

The unit continues stepping up power through authorized power plateaus. ASN cleared operation above 25% power in early 2025, followed by additional authorizations after turbine-side adjustments. Full-power operation is expected by late 2025, ahead of the first major maintenance outage—Visite Complète 1—planned for 2026.

Economic Reality and Strategic Impact

Now France’s 57th operating reactor—and its most powerful—Flamanville 3 joins Olkiluoto 3 in Finland and Mochovce 3 in Slovakia as one of Europe’s few major nuclear additions this decade. For EDF, the project’s value is in its engineering blueprint. The company has said that lessons from Flamanville 3 could reduce the cost of subsequent units by roughly 30%, particularly as France transitions to the standardized EPR2 design. That program incorporates a simplified architecture, greater component standardization, modular construction practices, expanded mock-up and training infrastructure, and tighter integration between engineering, manufacturing, and site execution. EDF has also moved away from the turnkey contracting structures that characterized earlier EPR projects in favor of more centralized procurement and oversight.

Cost, however, remains a defining challenge. The French Court of Auditors estimated in early 2025 that with total construction costs nearing €23.7 billion—including financing costs—Flamanville 3’s electricity would need to be priced at about €138/MWh to yield a 4% return over a 60-year life at a 75% capacity factor. That far exceeds the €70/MWh price cap agreed for nuclear output beginning in 2026, and it underscores a need for long-term contracts or state-backed support. The Court also warned that France remains “far from ready” to execute its EPR2 program, citing unfinalized cost estimates, design delays, and insufficient industrial capacity—and recommended postponing the final investment decision until financing is secured. Whether the EPR2 program can deliver faster, cheaper, and more predictable projects will determine whether Flamanville 3 stands as a hard-won turning point or a cautionary benchmark.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).