Many networks across a variety of verticals including government, military, financial services, power plants, and industrial manufacturing have been so-called “air-gapped.” This means they are physically and logically isolated from…

Technical articles on all aspects of power plant operation, preventive and predictive maintenance, planned and unplanned outages

Many networks across a variety of verticals including government, military, financial services, power plants, and industrial manufacturing have been so-called “air-gapped.” This means they are physically and logically isolated from…

ST. LOUIS, Mo. – Nov. 8, 2019 – Mississippi Lime Company’s (MLC) specialty operations in Ste. Genevieve, Missouri has received the ISO 9001:2015 Quality Management Systems Certification from NSF International…

World’s Only Clamp-on Steam Meter Edgewood, NY, November 8th, 2019 - FLEXIM is pleased to announce its development of the one and only, ultrasonic clamp-on steam meter. This has been…

Drones represent a classic good news/bad news scenario. The good news is great. The bad news is terrifying. On the good news front, drones can keep utility-sector workers safely on…

Of the many challenges power and industrial plant maintenance teams face, stretching the capabilities of their ultra-lean staff is one of the most critical. Assets can range from industrial generators,…

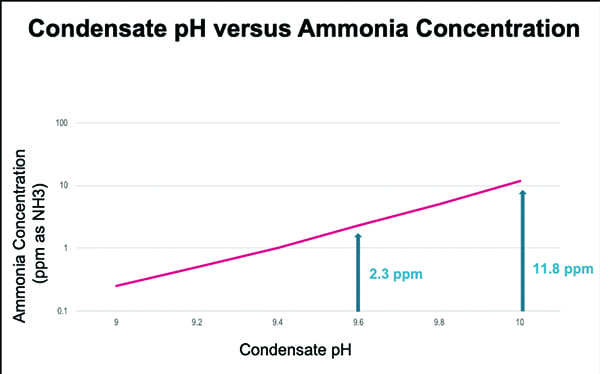

Cycle-chemistry guidelines for combined cycle power plants have changed over the years, with pH frequently maintained between 9.6 and 10.0 today. That can cause problems with condensate polisher operation. Plant…

Is your plant’s natural disaster preparedness plan leaving your site vulnerable? This article provides some best practices to help you prepare for the worst. At some point in a plant’s…

Good infrastructure is an essential component for the economic growth of a country, and power plays a crucial role in infrastructure development. India is home to 18% of the world’s…

Ansaldo Energia Group, through Ansaldo Nucleare SpA, in association with Candu Energy Inc., a member of the SNC-Lavalin Group (TSX:SNC), were awarded a 9.727 million Euro contract by Societatea Nationala…

(PARUZZARO, Italy – October 24, 2019) –SPIG S.p.A. (SPIG), a subsidiary of Babcock & Wilcox Enterprises, Inc., has completed a cooling tower upgrade project at Bell Bay, Tasmania, a production…