Earlier this year, nuclear technology giant Framatome and power sector lifecycle management service company Kinectrics launched an Ontario-based joint venture, Isogen, whose mission is to enable the use of CANDU reactors to produce critically needed medical isotopes. The development points to an expanding function for nuclear power plants beyond the production of carbon-free electricity that could furnish them with a lucrative source of revenue.

Isogen’s first partnership is with Bruce Power, Canada’s only private sector nuclear generator. The company was established in 2001 by TC Energy and three worker advocacy groups, and today, it operates a fleet of eight CANDU reactors that produce about 30% of Ontario’s power. The nuclear generator in July 2019 joined forces with Framatome and Kinetrics to advance an innovative project that will leverage the 2.4-GW power facility’s scale and redundancy to produce lutetium-177 (Lu-177). As experts have noted, this key medical isotope can be used in targeted radionuclide therapy to treat cancers such as neuroendocrine tumors and prostate cancer, because it can destroy cancer cells while leaving healthy cells unaffected.

In November, the companies also partnered with Isotopen Technologien München (ITM) to leverage the Munich, Germany-based biotechnology and radiopharmaceutical group’s manufacturing methodology of no-carrier-added Lu-177—known by its trademark, “EndolucinBeta.” ITM noted that the partnership stemmed from a successful feasibility study completed earlier in 2019 that showed Framatome, Kinetrics, and Bruce Power are “uniquely positioned” to fulfill the necessary requirements to establish isotope delivery units at the Bruce Power reactors. The company said the study “examined factors such as technical, medical and nuclear regulatory requirements, radiation protection and waste management. It also verified the specific requirements of compatibility with ITM’s target and processing technology.”

As Bruce Power explained, the project leverages infrastructure work underway at the site to extend the facility’s life to 2064. Under the province’s long-term energy plan, the company has set out on a CA$13 billion program to refurbish six of the eight units on its site on the eastern shore of Lake Huron near Tiverton, Ontario. Under the life-extension project, Bruce Power kicked off a major component replacement project this January that focuses on the replacement of key reactor components in Units 3–8, including steam generators, pressure tubes, calandria tubes, and feeder tubes. Bruce Power said the life extension of each unit (starting with Unit 6 in 2020, Unit 3 in 2023, and Unit 4 in 2025) “will add approximately 30 to 35 years of operational life, while other investments will add a combined 30 reactor years of operational life to the units.”

Framatome noted that Bruce Power is well-suited to foster the specialized isotope production system because it is a founding member of the Canadian Nuclear Isotope Council (CNIC)—an entity that strives to develop “collective solutions” to maintain Canada’s status as a world leader in the production of radioisotopes. For nearly 30 years, four of its reactors have offered a significant source of sterilization cobalt-60 (Co-60), an isotope typically sourced from nuclear companies that is widely used to sterilize medical devices such as sutures, gloves, and syringes. In fact, low-specific-activity (LSA) Co-60 from Bruce Power sterilizes more than 40% of the world’s single-use medical devices, the company said.

|

|

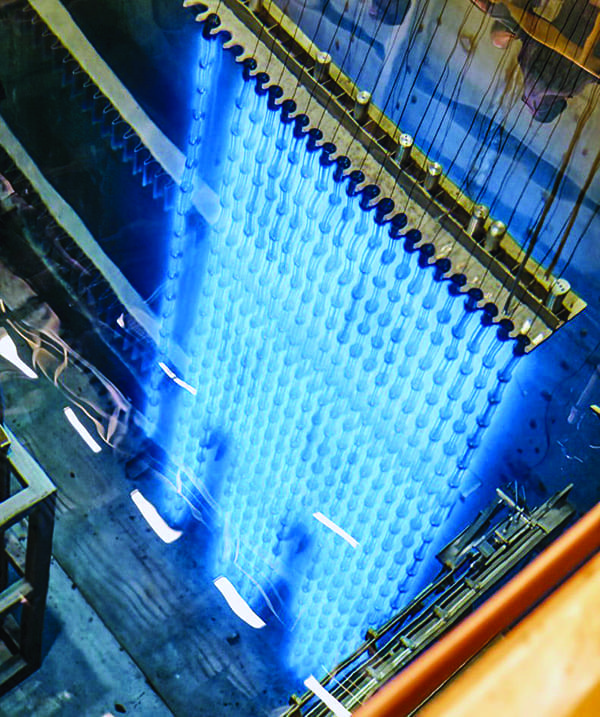

1. Bruce Power in March 2019 completed its first harvest of medical-grade cobalt-60, which will be used to help diagnose and treat brain and breast cancers. Courtesy: Bruce Power |

Last year, meanwhile, Bruce Power forayed into production of medical-grade high-specific-activity (HSA) Co-60, which is used worldwide to battle complex cancer—such as brain and breast cancer—and radiation therapy. In March 2019, it completed its first harvest of HSA Co-60 isotope (Figure 1), which spent nearly two years at Unit 7 before it was relayed to health science company Nordion for processing.

Stemming from that achievement, in September, Bruce Power entered into a collaborative framework with Nordion and medical technology company Xcision to use HSA Co-60 for GammaPod, Xcision’s stereotactic radiotherapy system that provides high-precision noninvasive treatments for brain and breast cancers. Co-60 is also a key component in sterile insect techniques, which could suppress Zika virus–carrying mosquitoes and agricultural pests like pepper weevils, for example, and food irradiation.

As Bruce Power explains, the power facility receives Co-59 pellets and slugs from a manufacturer (which sources them from a mine), and they are then installed as adjuster rods in a reactor and activated to become Co-60. After harvest, the rods are suspended on the wall of the secondary fuel bay, about 14 feet below the surface, so that the water can shield employees from the radioactivity. “From the reactivity mechanism deck over the fuel bay, Bruce Power’s specialized fuel handlers extract the individual irradiated rods and place them in a shielded flask to be shipped to Nordion’s facility,” it said.

Isogen’s Lu-177 isotope production system will seek to turn targets into medical isotopes through irradiation of ytterbium-176 (Yb-176), similar to the process that Bruce Power uses to produce Co-60. The Yb-176 source material, delivered by ITM, will be sealed in special containers and placed in an isotope production system in one of the Bruce Power reactors for about two weeks, and the resulting containers of Lu-177—each of which generates enough isotopes for about 200 patient treatments—will then be sent for processing and distribution to health care facilities worldwide, Framatome told POWER. The process does not generate any nuclear waste “as all the materials are either used for treatment of patients or are recycled to be used to produce more of the isotope,” it explained. For now, Isogen estimates that, following all regulatory and other approvals, isotope production could begin in 2022, with the goal of scaling based on demands for Lu-177 and other isotopes.

Development of medical isotope production capabilities appears poised to ramp up, owing to tight supplies of the short-lived element forms. As the Nuclear Energy Agency suggested in a November 2019 report outlining medical isotope demand and capacity through 2024, for example, concerns about supply reliability of two extremely short-lived key isotopes, molybdenum-99 (Mo-99) and technetium-99m, which are used in nearly 80% of all nuclear medicine procedures, have been magnified over the past decade, owing to unexpected shutdowns of aging research reactors and processing facilities. Last October, the U.S. Nuclear Regulatory Commission accepted an operating license application submitted by Shine Medical Technologies to operate a low-energy, accelerator-based neutron source (instead of a nuclear reactor) in Janesville, Wisconsin, to produce two-thirds of the nation’s patient demand for Mo-99, as well as other isotopes, including Lu-177. In November, Isotek Systems, TerraPower, and Oak Ridge National Laboratory agreed to extract thorium-229 from the Department of Energy’s legacy uranium-233 inventory and use it to produce actinium-225, an extremely rare isotope that has a vast potential to serve as the basis for groundbreaking cancer treatments.

Meanwhile, in February, Westinghouse Electric signed a letter of intent with Nordion to develop an “innovative isotope production technology” that will allow Co-60 to be produced in pressurized water reactors. Nordion, notably, in February 2019 acquired technology patents related to Co-60 production in light water reactors from GE-Hitachi Nuclear Energy Americas, which means it also has the intellectual property to enable Co-60 to be made in boiling water reactors. The company has promoted that capability, noting that the technology’s viability has already been demonstrated in a pilot program that successfully produced approximately one million curies of Co-60 at two U.S. reactors.

More recent non-CANDU examples of reactors adopting Co-60 production are centered in Russia. While Rosatom’s Leningrad reactor, an RBMK graphite-moderated design, has been producing Co-60 for more than 20 years, Rosatom recently began production at several other RBMK reactors, including at Kursk-4 in November 2018 and all three Smolensk units in November 2019.

—Sonal Patel is a POWER senior associate editor.