predictive maintenance

-

T&D

It’s Time to Listen to Transformers

A transformer fire at Heathrow Airport earlier this year triggered cascading power outages, cutting electricity to more than 66,000 homes, grounding more than 1,300 flights, and causing losses of up to £100 million. According to a recent report, the fire started because of a fault in a 50-year-old asset that subsequently led to short circuiting […]

-

O&M

Creating a Living Asset: The Role of AI-Enhanced Digital Twins in Autonomous Operations

The convergence of artificial intelligence and digital twin technology is emerging as a transformative solution, enabling power producers to shift from static control systems to dynamic, self-optimizing

-

O&M

AI-Driven Predictive Maintenance: The Future of Reliability in Power Plants

Artificial intelligence (AI) is transforming the energy sector, helping power plant operators optimize efficiency, reduce emissions, and prevent costly equipment failures. By analyzing vast amounts of real-time data, AI models can identify anomalies in equipment behavior, optimize fuel consumption, and enhance overall plant performance. According to industry estimates, AI-driven analytics can reduce maintenance costs by […]

-

O&M

The Evolving State of Power Plant O&M

As power plants confront aging infrastructure, surging demand, and the sweeping changes of rapid electrification, operations and maintenance (O&M) are being redefined to tackle unprecedented challenges and

-

O&M

O&M Innovation in the Power Sector: The Latest Tools Redefining Asset Optimization

As the power sector grapples with aging infrastructure, stricter sustainability mandates, and the rapid integration of renewables, innovation in operations and maintenance (O&M) has become critical to

-

O&M

Cut Downtime and Costs with Predictive Maintenance (PdM): Here’s How

Predictive maintenance (PdM) is transforming power plant operations by leveraging artificial intelligence (AI), data analytics, and automation to prevent costly equipment failures. Learn about real-world

-

O&M

POWER Magazine February 2025 Operations and Maintenance Special Report Preview

POWER is the one brand that addresses all electric power generation and related technologies and fuels across North America and around the world, providing insight into this increasingly complex industry. Established in 1882, it is dedicated to providing its global audience with exclusive analysis of the latest trends, best practices, and power generation and related […]

-

Trends

How Nuclear O&M Is Evolving for the Emerging Power Paradigm

In its quest to drive down costs while boosting safety, the nuclear industry has ramped up efforts to streamline operations and maintenance (O&M). New approaches target efficiency and resilience. If there

-

Connected Plant

Enhancing the Potential of Condition Monitoring Using Vibration Information

Condition monitoring can transform how power plants operate and maintain their assets. This article argues that to exploit the full potential of condition monitoring, it’s necessary to use data to acquire

-

Full Coverage

AI’s Paradox in the Power Sector—Unleashing Potential but Confronting Uncertainty

Artificial intelligence (AI) is rapidly transforming the power sector, offering unprecedented opportunities for efficiency and innovation. But as AI applications proliferate, new challenges are emerging. How will industry navigate the potential and challenges that accompany this digital revolution? Recent efforts to overhaul the long-established energy system in alignment with decarbonization and decentralization have introduced new […]

-

Interview

The POWER Interview: Predictive Maintenance Key for Solid Solar Performance

Operators of utility-scale commercial solar farms know the importance of predictive maintenance for their installations. Being proactive when it comes to developing operations and maintenance (O&M) programs can help operators anticipate equipment failures, and also streamline repairs in the field, allowing O&M service providers to better manage and plan staff assignments, find spare parts, and […]

-

Solar

Dialing in Data Key to Developing Successful Predictive Maintenance

Data analysis is helping operators in the solar power sector develop more efficient systems that optimize operations and deliver cost savings. Utilities and other developers of solar power installations know

-

Connected Plant

The Benefits of Remote Monitoring for Transformers and Other Electrical Equipment

Obtaining real-time operating data on power plant and substation equipment has never been easier. The sensors, transmitters, and systems needed to monitor important parameters are readily available and highly

-

T&D

Should You Make the Switch to Digital Integrated Power Transformers?

Are the benefits of digital integrated power transformers worth it? Smart transformers with exciting new technologies like Internet of Things (IoT) and artificial intelligence (AI) are among the next generation of energy equipment hitting the market today. Many organizations are considering switching to these cutting-edge transformers, but are unsure about the pros and cons. What […]

-

IIOT

Don’t Fix That … Yet: How IoT-Enabled Sensors Predict Maintenance and Streamline Operations

The traditional approach to maintenance has two motors that keep it running. The first motor is proactive service: regularly maintaining equipment, following a schedule to ensure each element is running smoothly before repairs are needed in order to prevent a breakdown. The second motor is to repair once a breakdown happens. While the first part […]

-

O&M

Monitoring of Power Station Components: Predictive Maintenance in Flexible Plant Operation

An innovative software program, coupled with an experienced team of engineers, allows plant operators to evaluate creep and fatigue stress in components exposed to more frequent cycling, thereby identifying

-

Connected Plant

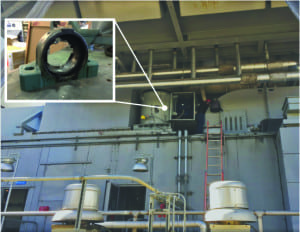

How NRG Energy Uses IIoT Technology to Optimize Asset Performance and Predict Failures

Industrial Internet of Things (IIoT) technology is changing how power plants operate. One generating station incorporated new wireless vibration sensors with data from its existing historian system to better

-

Interview

The POWER Interview: The Importance of AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are becoming synonymous with the operation of power generation facilities. The increased digitization of power plants, from equipment to software, involves both thermal generation and renewable energy installations. Both AI and ML will be key elements for the design of future energy systems, supporting the growth of smart […]

-

IIOT

The POWER Interview: Exelon Discusses Digitalization

Digitization in the power generation sector continues to expand. Its goal in simple terms—providing easy access to data for power plant operators and engineers, enabling the use of advanced analytics to improve equipment performance and efficiency—has resulted in reduced operating costs for utilities, and also has enhanced plant safety. POWER’s upcoming Connected Plant Conference, set […]

-

News

Predicting the Future? There’s an App for That

Power plant operators are turning to predictive maintenance applications to monitor equipment and collect performance data. Asset management systems, using artificial intelligence and other methods, are part

-

Technology

The POWER Interview: What Is Big Data?

The term “Big Data” is used frequently by tech-savvy power industry professionals, but what does it really mean. To get an insider’s perspective, POWER posed the question to Akshay Patwal, strategic business manager with Siemens Energy. Patwal leads the development and commercialization of digital business transformation projects, using big data platforms and analytics to create […]

-

Press Releases

Digital leader ABB provides Enel Green Power with predictive software for sustainable hydro operations

ABB is partnering with Enel Green Power to deliver innovative predictive maintenance solutions that will lower maintenance costs and transform the performance, reliability and energy efficiency of its hydropower plants throughout Italy. The three-year contract will enable 33 of Enel Green Power’s hydroelectric plants, comprised of about 100 units, to move from hours-based maintenance to […]

-

Connected Plant

Temperature Monitoring Protects Low-Voltage Assets

Early detection of increased temperatures helps avoid power distribution asset-related failures and unplanned shutdowns. Wireless technologies make implementing this predictive maintenance solution practical

-

Press Releases

Enel Green Power First in North America to Deploy New Predictive Maintenance Technology at Geothermal Plants

The software technology, created by NarrativeWave, will enable Enel Green Power North America to better anticipate maintenance needs at its geothermal sites saving the company time and money The technology has now been deployed at all of Enel Green Power’s North American geothermal sites, Cove Fort, Salt Wells and Stillwater BOSTON, May 30, 2019 (GLOBE […]

-

Connected Plant

Digitization and Analytics in Power Plants

A key aspect of any digitization effort is providing easy access to data by engineersand other experts so they can perform advanced analytics to improve outcomes. In the March 2018 issue of POWER, an article

-

IIOT Power

Using Predictive Analytics to Keep Up with Energy Demand

Silicon Valley Power implemented a system using machine-learning technology to monitor critical power plant components. The solution has proven to reduce downtime and save money. Furthermore, its wireless

-

IIOT Power

Moving from Preventive to Predictive Maintenance with Advanced Analytics

Predictive maintenance is preferred over preventive maintenance for critical assets, but the correct application of advanced analytics is required to realize full value. Power plants of all types have a host

-

O&M

Improving Plant Efficiency with Pump Performance and Condition Monitoring

All the elements necessary to implement a complete and economical pump monitoring system are now available. It’s simply a matter of assembling the pieces. Within the walls of a thermal generating plant using

-

O&M

Software Helps with Proactive Maintenance

Utilities and power plant equipment providers know that maximizing the value of their assets includes keeping them maintained and online. Minimizing downtime is critical, certainly when it comes to keeping the

-

IIOT Power

Unsupervised Machine Learning: The Path to Industry 4.0 for the Coal Industry

Artificial intelligence and machine learning aren’t just fictional pieces of futuristic Hollywood movies. Power plants can deploy these innovative technologies today to more accurately predict the condition