In this episode of Schweitzer Drive, host Dave Whitehead sits down with Dr. Luca Oriani, President of Long-term Operations at Westinghouse, to explore the future of large-scale nuclear energy. They discuss the resurgence of advanced nuclear reactors, the lessons learned from the AP1000 deployment at Plant Vogtle, and how modern technology is reshaping the safety, scalability, and sustainability of nuclear power. This is a must-listen for anyone curious about how nuclear fits into our clean energy future.

Listen on Spotify

Listen on Apple Podcast

Transcript

Intro:

Welcome to Schweitzer Drive, a podcast where we explore what goes on between the generation of electricity and the light switch. Join Dave Whitehead as he interviews the entrepreneurs, innovators, and experts who are inventing the future of electric power.

Dave Whitehead:

In recent episodes, we’ve delved into the world of advanced nuclear reactors, spotlighting two innovative startups focused on small-scale solutions. As the push for decarbonization gains momentum and the need for more electricity generation increases, there’s a renewed interest for large scale nuclear reactors in the United States.

Today, I’m excited to welcome Dr. Luca Oriani, President of Long-term Operations at Westinghouse, a company that’s been at the forefront of innovation in the energy sector for more than a century. We’ll dive into the latest advancements and work going on in the realm of large-scale nuclear power.

Dr. Oriani leads the development and delivery of instrumentation and control systems, training, and parts that support the global operating fleet of nuclear power plants. Most recently, he served as Senior Vice President and Global Chief Engineering Services Officer, leading the development and engineering hub of Westinghouse, and overseeing its global components manufacturing plants. He’s worked at Westinghouse for over 22 years. He holds a doctorate and a master’s degree in nuclear engineering from Polytechnic University of Milan in Italy.

Dr. Oriani, thanks for taking the time to talk with me today. Let’s jump right into this.

Dr. Luca Oriani:

Thanks, David. Thanks for having me.

Dave Whitehead:

This is going to be fun. I’ve been looking forward to this podcast for a while now.

Westinghouse has been a key leader and innovator in the nuclear power industry. Can you highlight some of the company’s history in nuclear energy?

Dr. Luca Oriani:

Yeah, so when you look at the history of Westinghouse, it dates back 139 years, right? [It] started in the Pittsburg area, in Western Pennsylvania, that has been our historic home. And we have been involved with nuclear power since before nuclear fission was invented.

The largest atom smasher to study physics in 1936 was actually built by Westinghouse, literally three years before the discovery of nuclear fission revealed the potential of actual nuclear power.

We were engaged in the first Naval application with the [USS] Nautilus, and then with the first land-based reactor in the United States, at Shippingport [Pennsylvania]. And over the years, we have participated not just in the deployment of the nuclear fleet, but also in the development of an entire industry, both in France and Korea and in a number of other countries, to the point that today almost half of the reactors in the world have been built directly or indirectly on Westinghouse technology.

Dave Whitehead:

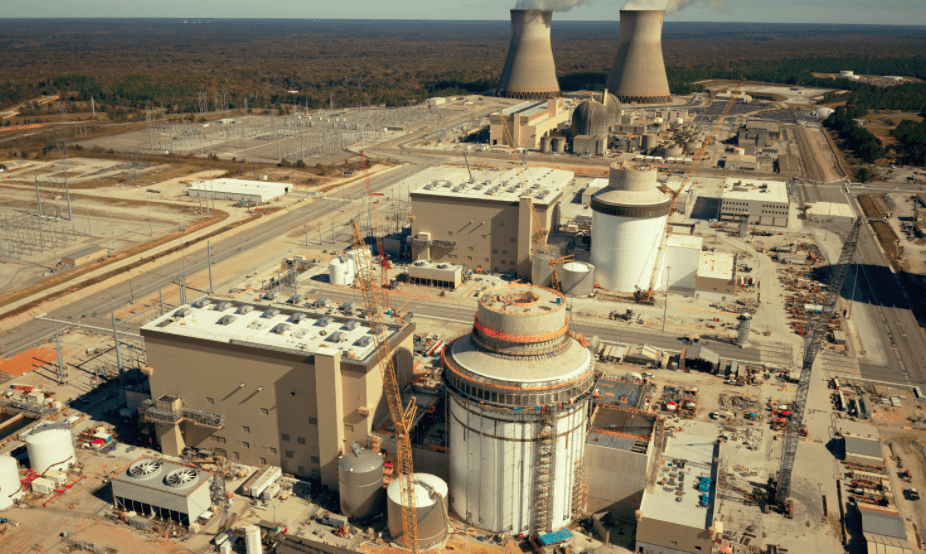

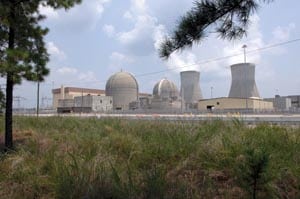

Westinghouse AP1000 reactors are powering the largest generation of clean zero-carbon electricity in the United States at Plant Vogtle near Waynesboro, Georgia. When units three and four came online in 2023 and 2024, they were the first nuclear reactors built in the United States in more than three decades. Can you talk about some of the challenges this project faced as well as some of the lessons learned?

Dr. Luca Oriani:

Yeah, this is a great question. I’ll split it in two parts if it’s okay, David.

So, the first one, I’ll talk about what does that AP in front of 1000 stand for. And that stands for Advanced Passive. So, during the 70s and 80s, the nuclear industry faced a challenge that was recognized first in the United States, which is the fact that we were building plants and we were making them safer and safer. But we had created a situation in which making a plant safer and [continuing] that development required us to continue to increase the cost of the plant, making them larger and larger, more and more expensive.

The United States at that stage decided that we needed to investigate the different methods to ensure that this safe and clean form of electricity could be deployed in a more effective manner. And that led to the development of what’s called passive technology.

So traditional nuclear power plants from the inception of the nuclear industry, the mid 50s to roughly the end of the last century, were based on what’s called an active passive technology. That uses pumps typically and valves to provide multiple, redundant train of safety system. That has allowed us to achieve the safest form ofproduction of energy in the world. And it’s a system that tends to mitigate through multiple lines of defense and barriers – challenges to the safety of the plant.

The problem is the system requires very complex networks of pipe, valves, cables, [and] concrete. And they become literally a spider web of supporting systems . What we tried to develop, and we succeeded – and this was a joint program between Westinghouse for [a] pressurized water reactor, General Electric for [a] boiling water reactor, the US Government, the Department of Energy, National Labs, and utility groups in the United States – to develop a technology that we defined as passive.

In that case, we rely on fundamental forces of nature, like gravity, to replace pumps. What’s the advantage? Gravity doesn’t need [an] oil-supporting system [or] ventilations. It just works; water works. And essentially that allows us to create plants that are a lot simpler to build.

If you compare an AP1000 to some of the competitors, both European and Korean reactor[s], or even some of the previous generation plants in the United States, the ratio is about between half and three times less in key quantities. And that’s what really drives the cost of a nuclear power plant. People get fascinated by the nuclear components, but what really drives the cost of the nuclear power plant is the labor to build them. And that’s driven by concrete, cables, [and] pipes. And the capability of reducing your conduits by three times, your pipes by four times, your concrete by two and a half times, gives you plants that are smaller, more compact, and safer at the same point. To the point that when they go into operation, these plants are beating all records of availability because there’s fewer things that can fail in the operation of the plant.

Now when it comes with the introduction of the technology, these are massive infrastructure projects. We have seen in the deployment of the AP1000, a cost per unit that literally drops by a factor of two and a half to three times going from the first unit in a country to the end unit in a country.

So those were the really big challenges we had with the first wave of the AP1000, right? These are modular plants – they are designed to be built and assembled as much as possible in factories. The timing of the design, the learning how to build them. The United States hadn’t built [a] nuclear power plant for 25 years. There’s a generation of electricians, pipe fitters, welders, other craftsman, project managers, [and] project controllers that needed to be grown and developed. And, those were some of the main challenges we had with those projects. As a country, we are learning again how to build nuclear power plants. The next two will be cheaper, and by the time we get to the sixth or seventh, we tend to operate the same way we do when we build an aircraft carrier, right? The first one in a series is always a lot more expensive, but we stay disciplined, and we build a fleet of those plants before we go off and try to invent a new one.

Dave Whitehead:

Sticking with the Vogtle units, how are Vogtle units 3 and 4 different from units 1 and 2 in terms of technology and safety? And looking ahead, what are some of the advances we’ll see in large scale nuclear power?

Dr. Luca Oriani:

So, I think that if you look at it, it’s what we discussed before.

Vogtle 1 and 2 are the culmination of our active nuclear safety plans, right? So, it’s the culmination of that development that went from the 1950s to the 1980s, and resulted in extremely efficient operations. They are some of the best units in the country. The operator, Southern Nuclear, achieves impressive records of reliability and availability for those plants. The AP, the Vogtle 3 and 4 are new plants, so they use the basic nuclear component, but they implement this passive safety approach, so they are simpler to operate.

With the first generation of nuclear power plants, it took us almost several decades to get them to a level of operation that is the current strength of the nuclear industry, right? Those plants always produce power – come rain or shine, come hurricanes or snowstorms. Nuclear plants just produce safe power.

With these, passive units, we’re getting to those levels of reliability no longer in the span of decades, but literally in the span of years. Those units are already running at 93% – 94% capacity factors, and they are still in what, for any other technology, you would consider almost a shakedown run, the first two or three operating cycles between refueling.

I think that’s what we are seeing; more and more plants and new concept[s] are adopting that passive technology approach. There is always going to be that first of a kind barrier. I think that’s one of the things that for us is fundamental, and we see the benefiting country that adopt that fleet deployment mentality. The United States in the 1970s, France in the 1970s and 1980s, China today. That discipline tokeep building the plants, get patented, deploy a fleet of units-to the point that you get to build them at the third – your sixth plants are typically a third of the cost and have the schedule of your first ones.

Dave Whitehead:

What are there, about a hundred or so nuclear plants in the US right now?

Dr. Luca Oriani:

Yes.

Dave Whitehead:

Yeah. Right. Right around there. And we talk about Three Mile Island, and that’s really the only one I can think of right off the top of my head where there was, you know, some concern about safety. But if we, if we step way, not even way back, just a little bit back, right? The nuclear industry, certainly in the US, and pretty much in the rest of the world, has been a really safe and efficient way to generate electricity. Certainly, there’s a lot of interest in carbon-free electricity, right? Whether we’re talking about solar or wind turbines or whatever. But I am convinced that if we want reliable, clean electricity, you end up at nuclear. And then, really from my perspective, the only question is how do you get from now to this nuclear, nuclear state? I don’t know what your thoughts are.

Dr. Luca Oriani:

That’s where you see the different elements of that strategy. I think, David, you have it exactly right. At the end of the line, when we look at energy, we look at an energy mix. There are strengths and benefits to all different sorts of energy mix. Nuclear clearly has a very strong advantage once deployed, it’s very reliable.

If you look at casualty and injury indexes, it’s orders of magnitude lower than other forms of energy, including renewable. There are risks that are inherent to any energy sources. Construction of wind turbines carries inherent risk with the complexity of the construction and the elevation at which those operations occur. I think at the end is, a good balanced energy mix is what makes a country strong and independent. And it also achieves inherently a level of clean energy that is superior to going a single route.

And you can see the paradox of some countries, like Germany, where an over-reliance and an over specification of one source of energy end[s] up increasing not just the cost of energy, reducing the availability of energy, but also reducing the capacity of the country to sustain an industrial system. That mix of energy sources.

And that’s one of the reasons why modern nuclear power plants are designed to be able to change power very fast. If you look at the modern AP1000, it can change literally power at five megawatts per –essentially about 60 megawatts per minute, 300 megawatts every five minutes, the equivalent of a combined cycle plant in terms of changes. Why? Because it’s designed to work, not against, but together other sources of energy that countries may use, be it hydropower, wind, solar, or other sources and means to produce clean energy.

Dave Whitehead:

I didn’t realize that. I always just assumed, I don’t know why, but for whatever reason, that a nuclear plant would, you’d want to use it for baseload, you know, let it kick out three gigawatts or something. And it, that’s all it does day in and day out. And if we need peakers or something like that, we’d throw on a gas turbine. I didn’t realize that, you know, scaling up or scaling down is a design for the AP1000.

Dr. Luca Oriani:

Yeah, and the reason is because that’s the exact way you want to use them, right? If you have an electric system in which, like in the United States, your nuclear power plants make about 20% – 25% of your electricity generation, then of course you prefer to run them baseload because you just get more efficient operations from them. But you look at countries with a higher percentage of nuclear power, like France, there has been already a practice of using nuclear plants in load follow maneuvers. And so, when we introduced a new fleet of plants, we wanted to make it a lot faster and a lot easier, so that you can integrate and stabilize a grid that is getting higher in renewable and more intermittent power sources.

Dave Whitehead:

Yeah, and your source of power brings some stability to the grid too, right? With a big spinning mass, not these capacitors and IBRs, if you will, that are not nearly as, I don’t know, robust as a big spinning turbine or something.

Dr. Luca Oriani:

Correct. Yep.

Dave Whitehead:

Many of the Westinghouse nuclear projects in recent years have been outside the US. What’s the difference between what’s happening with nuclear power outside versus inside the US?

Dr. Luca Oriani:

So, that’s an interesting question because I feel that, again, I grew up in Italy before moving to the United States, and I’ve been here 25 years. And one of the things that always fascinates me is the way the United States looks at nuclear industry, and we use it as a tool to build a safer, and more stable world with number of our partners. But the nuclear industry is still fundamentally based on the Atom for Peace Speech from President Eisenhower in the 1950s. The United States had countries peacefully use nuclear energy as long as they are willing to not use it for other purposes. And that has been an extremely successful approach.

What that has led, also, is a situation in which we adapt to each country, right? When we build in the US, we make [it] in the US. When we build around the world, we create the competency to do that on a global basis – Canada rather than central Europe. And that creates [a] relationship that then are instrumental to both Westinghouse and the United States in terms of projection outside our projection globally.

And it creates a truly integrated global system that is different from, for example, Russian technology or Chinese technology or French technology, that tend to be very country specific, country control. So, we have done a number of projects outside the United States, but our two newest plants have been in the United States, right? The United States fleet has been, while the number of units has not increased, but the availability and the power produced by those units have kept increasing.

And we have worked, that’s a very large part of our business, is making sure that while we wait for those new fleet[s], those new standard construction of nuclear power plants, we keep making the operating fleet pattern right?

One of the characteristics of nuclear, is some of these nuclear plants are already in their 40 – 50 years of operation. They are going to be extended towards 80 years. We’re already looking at what would [it] take, what would be required to extend them safely to 100 years of operation. So, they require constant replacement of components, technology, methods, tools, [and] digital solutions that allow a fleet to keep growing on the existing asset base, as you build the capacity to build a new fleet to come after that.

Dave Whitehead:

Earlier you were talking about, hey, we had to relearn a bunch of stuff when we did the Vogtle plants. But, as you just mentioned, I think, Diablo Canyon, they wanted to, to extend or bring back on Three Mile Island, was it for Google or Microsoft? They wanted to bring that unit back on. And so, when we look at a workforce, are we seeing renewed interest in going to the nuclear industry or is it going to be a struggle, do you think, to get the right talent to be able to pull all this off?

Dr. Luca Oriani:

Dave, that’s an excellent one. If I look back, I’ve been [at] this for a long time, if I look back at the mid 2010s right? You would’ve seen, you would’ve probably looked at the workforce in the nuclear industry, and you would’ve raised an eyebrow to concern, where is the future coming? Right?

You look at it today, and the level of excitement we see in university, just Westinghouse hires over 500 engineers every year. Over 50% – 60% of them are in North America. The talent choice we have is extremely large. You look at the industry. This is a relatively young industry. Thirty percent of all our professionals and engineers are in the first five [to] six years of their career. So, which naturally then means you also have that level of experience for people that have been doing this for a long time.

But it’s a very strong pipeline of talent that we see. US universities are developing a large number of engineers, both nuclear engineers, but remember that as we discussed at the beginning, nuclear plants are a mix of a lot of different things. Yes, there’s a nuclear reactor, but there are electrical systems, there aremechanical systems, there are structural buildings – and the supply of talent that we see is significant.

One of the things we have also seen that is very interesting, and for us we tend to add the majority of our engineers in two regions – either the Western Pennsylvania-Ohio region or the Carolinas-Georgia, Carolinas, Southeast region. But the availability of engineer[s], the talent, the interest, and also, the number of people that we find that are interested in engineering that goes beyond the computer sciences or simply the coding and goes into the, getting on the field and helping construction build plants, spend [time] getting your hands a little bit dirty, and seeing both the steel and the paper.

The attraction of talent, and one thing that I find particularly encouraging, is our attrition rates are in the 6%, half of that being retired, which means that not only we can find the talent, but that talent stays, enjoys those jobs, enjoys the challenges. And I think it’s also that concept of doing something that provides a benefit for society, right? That a lot of different way to make money, but doing something that you know is creating clean, safe energy, that is contributing to the overall growth of society, and when you look at it, the availability of cheap electric power is the difference between a strong, rich, and growing country and a country that struggles.

Dave Whitehead:

Absolutely. The Biden administration signed an international pledge to triple the United States nuclear generation capacity by 2050, joining a host of other countries pledging to do the same. Based on your experience, what needs to happen to enable this goal to be met?

Dr. Luca Oriani:

That’s interesting, right, because I think the way the question is first, nuclear has proven to be a very bipartisan topic in the United States and internationally. And that, to me, speaks to a maturity of the debate on energy, recognizing the importance of it as an energy source, right? You don’t like when energy sources are made into a political debate because then, you know, then you [stop making a smart decision], you start making political decisions. And in this case, instead the general consensus globally, it’s not just the United States, [it] is the entire world. It’s not just a Democrat or a Republican, [it] is a bipartisan consideration. And, that is what we have seen in the industry.

I think the key thing, David, I think we have the manufacturing capability, we have the engineering capabilities. We have been growing that talent. I think the focus is going to be to actually convey the importance of trade. A strongly supported program to build a fleet of reactors, so that we can get interest from the newer generation in those jobs like electrician, pipe fitter, carpenter. These are very high paying jobs, but sometimes we have been developed more into a service economy. We’re seeing that trend shifting with the use of AI, but creating that pipeline in which people can see these as valuable careers, not just highly compensated, but something that provides years of projects to work on. That’s what we see as the key enabler, right? We are training the electrical engineers. We can get the electrical engineers. Can we then make this step into getting the electricians that actually then build those plants?

Dave Whitehead:

Yeah, I agree.

I recently read that your EVNC was one of two microreactors selected to be the first test bed at DOE’s demonstration of microreactors’ experiments, the first microreactor test bed in the United States. Will you tell us about that, and other nuclear technologies and innovations Westinghouse is currently focused on?

Dr. Luca Oriani:

Yeah, so that’s interesting. So, I’ll answer this in two parts. We’ll start talking first about the new plants. That’s where all the excitement is. But then, there’s a lot of innovation that goes into increasing the operations and effectiveness of the operating plants.

So, if we look at the operating plants, we talked about the AP1000, right? And we talked, and I always find it ironic that we talk about that like a large plant, while in reality an AP1000, the entire nuclear island of an AP1000 is less than half of a football field. Think about it, that’s 1200 megawatt of electric power, generating it by a surface that literally fits in half of a football field.

We also have a smaller version of an AP1000, which is what we call the AP300. Very similar technology targeted to different needs, right? Is a country needing gigawatts of power? Or does it need megawatts of power? What’s the structure of the grids? What fits better in those different situations?

One of the characteristics of nuclear power is that, however, it has always been at the level of grid scale electricity, right? You build a plant, and you can call them small, medium, large, whatever, but you’re still talking about large generating assets, 300 megawatts or what we call small modular reactors, are still the size of a combined cycle plant. So, they intended to be connected to a grid.

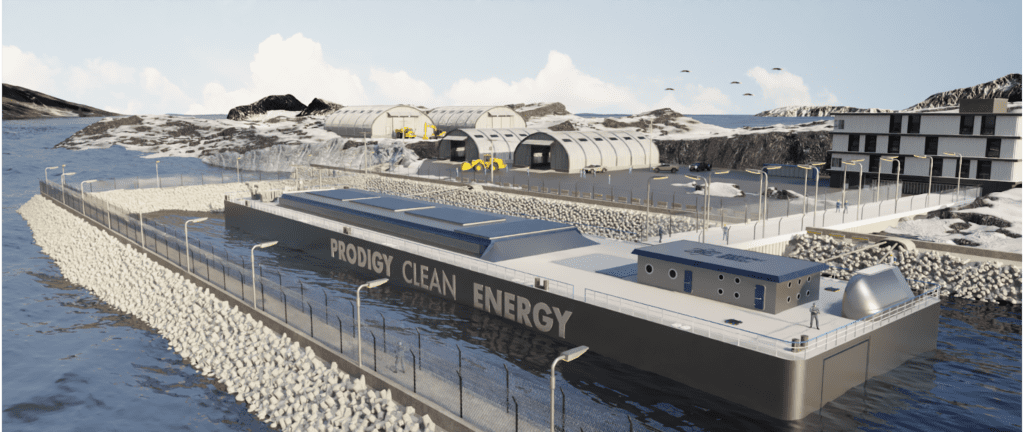

One thing that we have been developing and that we are testing now with the DOE, is the microreactors. These are single-megawatt type reactors, let’s say between three and 10 megawatts of electricity. They are intended to be connected to locations that may not have access to the grid. Remote locations in the [northern regions] of Canada or Alaska, military installations, research center in Antarctica, locations that don’t have – you can’t connect them to a grid and you can’t do 300, 600, 1000 megawatt of electricity.

The other fascinating thing, I think it also opens [up] what’s the ultimate frontier, right? At some point, we’re going to operate outside of a single planet . These microreactors are designed to not rely on gravity as one of their driving forces, which immediately enables them, and that’s clearly one of the things that we’re exploring is space-based application, whether it is deep space or planet type installation. That’s clearly one of the long-term goals for these technologies.

So, when you look at the operating plants, I think we talked about that importance, right? We have a very large fleet of assets, right? A hundred nuclear power plant in the United States. Some of the plants that have been shut down [are] being brought back online. You mentioned Three Mile Island, Crane Energy Center, that is [a] clean energy center that is being restarted, [and] the Palisades Plant. Increasing the efficiency, making sure that those plants can continue to operate safely and reliably for long periods of time, as you can imagine, requires a lot of innovation. That goes from advanced training methods; virtual reality application to the training of operators; that goes to the design and improvement in nuclear fuel, so that it can last longer between outages, that can produce more power from the same fuel assemblies; that can provide performance enhancement that continue to increase the safety of the plants; outage technology that relies on robotic applications more and more to support human intervention to make it more precise and accurate when we operate plants; new parts, digital solution[s] to replace analog solution[s], right, conversion. Remember, some of these plans were built before computers existed – I think that’s one of the fascinating things to me. We have this amazing technology and assets, the most advanced technology in the world, and a lot of these plants were built before anybody knew what PC would stand for or what a personal computer could even possibly be.

So, as you can imagine, how do I transition those plants? How do I replace those analog systems with digital systems by [achieving] a way to keep them operating in the same environment? That’s the application of artificial intelligence. We have our HiVE artificial intelligence solution, and how do you apply [it] responsibly and ethically to nuclear power? For us, it’s mostly in the area of, I like to call it, the grandmother rule of artificial intelligence. Train it to ask questions, not to give answers, right? So that it acts like sort of an owl, an advisor on the shoulders of engineers. And ask[s] them questions, help[s] them consider 70 years of knowledge, 70 years of lessons learned, 70 years of experience, and helps them come to the right decisions and conclusion and assessment of different technology.

When you look at it, nuclear vendors and Westinghouse in particular, they’re [a] technology company. They’re just a unique type of applied technology that is not just on [a] computer screen, but it’s actually also in steel and metal. The way even we make some of the new components for nuclear plants, right? No longer based on drawing, but on laser scanning of actual surfaces, and then engineers doing the machining directly interacting differently with advanced milling solutions. So, all those things, it’s a constant, it’s a fielding constant innovation , right? It’s the most advanced source of energy we have at this stage on this planet. And the amount of research that goes, both in introducing new solutions for new plants, but I would argue as importantly, ensuring the effective, safe, reliable utilization of what we have created in the last 70 years. Those are the two main areas of innovation.

Dave Whitehead:

Well, it’s certainly been an innovative industry for, and safe, very safe, for quite a while.

Dr. Luca Oriani:

And David, if you think about it, digital relays, right? SEL. Those type of things that you work with, us and others, to deploy. That’s something that 15 years ago, “no, I just use valves. I just use traditional relays.” So, all that technology, and one of the things that is unique on nuclear technology, while being so advanced, is the work we need to do before we put something on the market, right? You cannot afford [to make a] mistake. So, the amount of testing, the amount of qualification, it’s always interesting to me seeing when people compare it [to] some of the success we have seen in space exploration and space development, and not realizing that the difference with nuclear is, we can’t afford to blow up two rockets to get the third one right. It has to be right the first time, which of course, requires a much longer development and testing time before we put those solutions in the market.

Dave Whitehead:

Exactly. Exactly. So, the last handful of episodes for these podcasts, we’ve been discussing nuclear innovation, technologies, and policies. There’s a lot of buzz about new types of reactors, including SMRs and microreactors. But, there’s also been buzz about the return of large scale nuclear. In fact, I was watching CNBC this morning, and I think Meta is announcing a data center that will be two gigawatts. Right? And that’s not, you’re not gonna supply that with a microreactor at that point, right? So are we almost to the point where maybe , maybe there are some applications for these SMRs or microreactors, but if we’re really thinking about 10, 15 years, we should really be all in on these really big reactors just to meet all our energy demands, whether it’s data centers or cars or the electrification of everything.

Dr. Luca Oriani:

Yeah. I think the question, the question is the answer, David. You already gave my answer, so I’m not sure what…so I think you summarized that pretty much how we see this, right? We talked about those technolog , right? The AP1000, the large-scale nuclear power, the AP300, the small modular reactor, the eVinci, just looking at it from a Westinghouse point of view. We absolutely see a place for those eVinci and the AP300 SMR. But it’s clear that the workhorse for the nuclear industry in the foreseeable future is going to be that AP1000, that compact modular reactor.

We’re seeing them at this point, we have 30, we have six in operation, six that are all more than 50% complete, six more that have started conclusion, 38 units in the world that are at different stages in project development. And we see that as a wave, right? It started; Asia is clearly further ahead in terms of that development and deployment. Europe, especially central Eastern Europe, Poland, Bulgaria, [and] the Ukraine, as soon as hopefully the terrible war ends, those are going to be where that deployment occurs. And then it’s North America. And North American is driven by the fact this, at this point, with artificial intelligence, with demand of electricity, the demand needs are going to be in the gigawatt scale, and that can only be achieved with deployment of those large reactors. Now there’s going to be a space for the other technology, but that’s, what we see. We see that happening very soon, without getting in details, in terms of new, large scale nuclear projects in North America.

I think it’s fascinating to hear also, the new Prime Minister in Canada introducing this concept of the Am-Can Energy Fortress. Building that infrastructure, building that capability for North America to maintain a leading edge and energy is going to be the main currency of the future, which means we need both a short-term plan, which is the continuous expansion of the existing assets, and the midterm plan, because nuclear is interesting because people always think nuclear takes [a] long [time] to build. That’s true only for the first one. We are seeing countries right now that are introducing literally plant[s] at the pace that is almost one large plant per year. It’s just that you need to start, like any voyage, right? You need to start, and you need to maintain the discipline.

One of the difficulties as an industry we always have, is that we are really smart. So, we always have an idea for something else we want to do, and we need to get a little bit of that naval discipline, that recovered drove into the US Navy off, you build one, you build a fleet, and then after a few units, we’ll think about how to do another one. But you can’t keep building a first of something, when you know that the second, third, fourth, and fifth will be the one that really justify your investment in the first.

Dave Whitehead:

So that brings me to my sort of my final question here. So, we get a little bit, or I get a little bit excited about SMRs or these microreactors, but if I step back and look at the real energy needs, we need and the scale or how much we need, I think I quickly get back to the AP1000, and being able to mass produce those things or produce a significant amount of energy versus, you know, when we’re talking 10 megawatts, that’s really not a lot in the grand scheme of things, talking a gigawatt or 1.2 gigawatts, that’s a lot of energy.

Do you envision or are you guys thinking about, is there going to be an AP 2000 or something like that in the future? Or is the 1000 kind of the sweet spot from economics and power output or whatnot?

Dr. Luca Oriani:

So, we have seen a number. We’ve gone back and forth. We’ve also seen some of the new technologies that were developed in early 2000, deployed all over the world. And we see that thousand megawatts, which it’s actually a little bit of a misnomer because an AP1000 is actually about 1200-megawatt net electric, depending on the site where it is, between 1100 and 1200. But, we see that as the perfect size. The reason is also because the most efficient project is always in the two units or three units, right? So, you want to build those nuclear power plants, you don’t want to build a single one, you typically want to do a project with two, because the second one provides you with a significant synergy with the first one, and in fact is, they optimize each other’s schedule, right? So, the model of Vogtle 3and 4 is very similar to the ones we’re seeing all over the world, in which most of the AP1000 projects are a two-unit or a three-unit project.

And because of that, you also then have in a finite position on a grid, a very rapid introduction of relatively large amounts of megawatts. And we see that it’s more efficient to do two 1100 megawatts than try to do a single 2000 megawatts. And then you try to do two 2000 megawatts, and that starts to increase your investment level and the impact on the grid to the point that it’s harder to localize it. So, we see that approach of the bulk driven by the AP1000s with the availability of the AP300 for grids that are smaller or have a problem accommodating that large injection of power over a relatively short period of time, as a sweet spot for us to stay in combination. We keep improving on it. We’ll keep squeezing a few more megawatts, but that’s where we see that strategy looking like for us.

Dave Whitehead:

Well, it’s very interesting, you know, thinking about what are the sweet spots or how big can you go. And then the other thing you probably have to consider is you’re going to have to take a unit out of service for some reason or another, right? And if you had all your eggs in one basket, you probably wouldn’t want it, you probably wouldn’t want to do that either.

Dr. Luca Oriani:

That’s one of the advantages that it, two units [at] 1100-megawatts gives you over a single 2000-megawatts unit. The size of nuclear components also then becomes harder and harder to manufacture. So that a number of reasons we re-look at it periodically. We have looked at the 1700-megawatt version in the past. We just feel that that 1100 to 1200 megawatt is the sweet spot, in terms of component side, deployability, and effectiveness in construction.

Dave Whitehead:

You guys are doing some miraculous things. I hope to see some more AP1000 units throughout the rest of the United States.

Dr. Luca Oriani:

I do too.

Dave Whitehead:

I bet you do. You know, I really like, we talked about earlier, I think nuclear is our best option for having reliable dispatchable electricity 24/7 365.

Dr. Luca Oriani:

Completely agree.

Dave Whitehead:

Luca, thank you very much for talking to us. I’d love to have you on another podcast and at some point in the future to talk about how many other plants you guys have deployed around the US and around the world.

Dr. Luca Oriani:

I’m looking forward to it, David.

Dave Whitehead:

This was a lot of fun. Thank you so much.

Dr. Luca Oriani:

Thanks a lot.

Outro:

Thank you for stopping by Schweitzer Drive. Join us again as we learn about, explore, and celebrate electric power. For more information about the show, please visit S-E-L-I-N-C.com/Schweitzer Drive