The latest surface coating technologies offer massive improvements to the expected service life of compressors, turbines and pumps that are subject to surface oxidation, corrosion, erosion and heat damage.

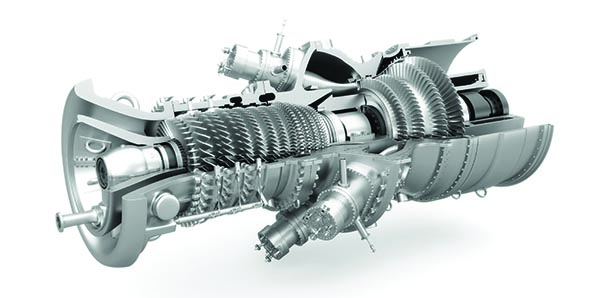

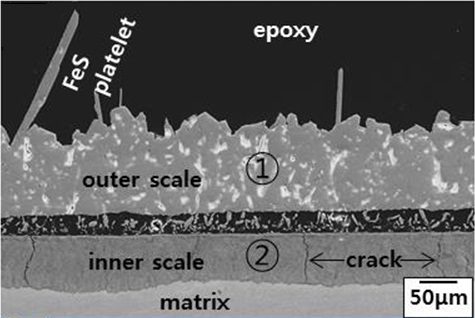

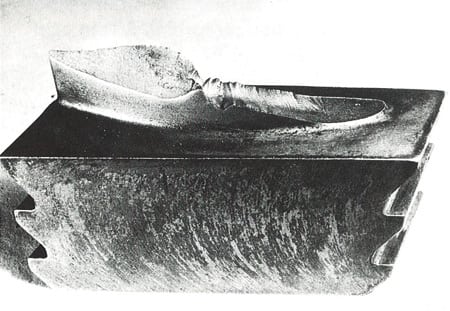

Turbines, compressors and pumps are all subject to a variety of environmental conditions that contribute to corrosion, erosion, fouling and various temperature related issues. Once the primary source of degradation has been identified, specific coating systems can be used to increase efficiencies, lengthen the interval between scheduled maintenance and reduce the occurrence of unscheduled maintenance events.

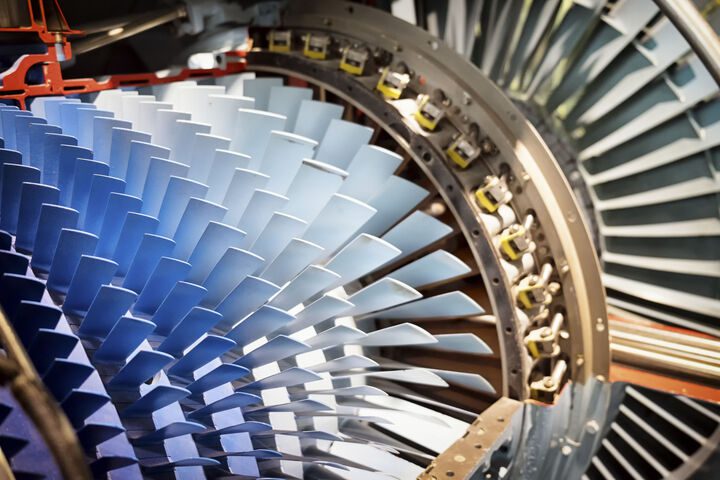

Applying corrosion inhibiting and surface finish enhancing coatings to compressor sections can increase efficiency and extend the service life of gas turbines. Moreover, the hot section components can also be supplemented with custom coatings that can minimize hot corrosion and oxidation, further extending the service life of these components.

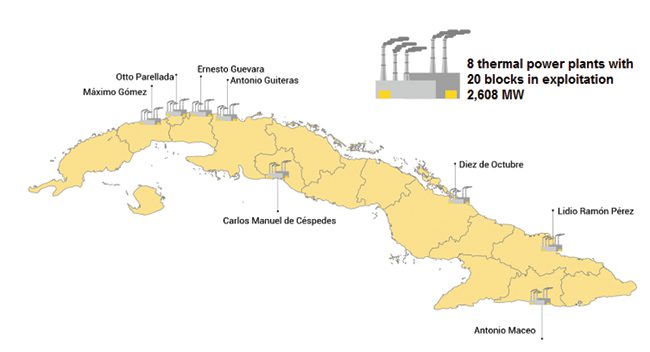

Modern coating technology can now be applied to legacy equipment that was not designed to take account of particulate-laden gas streams. In this way the original surfaces can be restored and upgraded with greatly improved anti-fouling and corrosion resistance. Implementing a new coating as part of a refurbishment project can significantly improve the performance and reliability of existing equipment.

Download the PDF below to see how Sulzer has addressed many of the challenges related to coating systems and is able to deliver a bespoke service that delivers improved reliability and extended service life to a wide range of applications.