Pairing Solar with Linear Generators Yields a Revolutionary C&I Energy Solution

|

A unique hybrid energy solution that ties in a rooftop solar array and a novel linear generator technology produces all power consumed at a Lineage Logistics cold warehousing facility in Colton, California. Showcasing a modern approach to evolving commercial and industrial (C&I) energy needs, the project can also provide dispatchability and fuel flexibility. These and other attributes make it a 2023 POWER award winner.

Cold storage warehousing is highly energy intensive, and for Lineage Logistics—the world’s largest temperature-controlled real-estate investment trust (REIT) and logistics solution provider—finding new and innovative technologies that could reshape its energy profile had long been an ambition. “We own and operate over 400 locations throughout the world,” Chris Thurston, director of Energy and Sustainability at Lineage, told POWER.

But while Lineage’s facilities are integral end-to-end logistical solutions, they represent a combined 2 billion cubic feet of capacity. Their consumption of power is a “big cost for us,” Thurston said, noting that most of the company’s facilities pull power from the grid. Meanwhile, Lineage has long been conscious of its carbon footprint. While the company in 2015 set out to reduce its energy intensity by 25% over 10 years, it met that target in just two years. In November 2021, the Novi, Michigan–headquartered company became a signatory to the corporate community–driven Climate Pledge, committing to achieve net-zero carbon emissions across its business operations by 2040. “And so, we had been on a journey to develop a self-sustaining warehouse where we could generate 100% of our power needs through clean technology,” Thurston said.

The company chose its Agua Mansa facility in Colton, California’s Inland Empire for the first-of-the-kind installation effort. According to Thurston, the site presented an ideal study. The warehouse, which serves as a cross-docking facility, is utilized to consolidate and redistribute shipments for a large grocery firm. It had the ideal square footage of roof space, and uniquely, “it doesn’t operate at our normal freezing temperatures,” he noted. “It’s closer to being a cooler at 30F, so using less energy per square foot overall. It was the perfect combination where we could solve for the 100% self-generation with a generator backup unit,” he said.

A Novel Generation Technology

Lineage tapped PowerFlex, a long-time distributed generation commercial solar partner, to install a 3.3-MW rooftop solar array on the warehouse comprising 8,426 individual solar panels (Figure 1). “Lineage and PowerFlex have formed a strong partnership over the past eight years, successfully developing more than 25 onsite solar PV projects across the U.S.,” PowerFlex Director Danny Ptak told POWER. However, Lineage also chose to pair the rooftop solar arrays with linear generators, a breakthrough new power generation technology launched in March 2021 by Mainspring Energy. Lineage estimated that while the 3.3-MW rooftop array could provide up to 73% of the facility’s needs, if two 230-kW Mainspring Energy Linear Generators were integrated onsite, they could firm the solar arrays for the additional 27% of the load, Thurston said.

|

|

1. Lineage Logistics installed a 3.3-MW solar array and 460-kW of linear generators at its Colton Agua Mansa facility in California’s Inland Empire. Combined, the solar array and linear generators produce 100% of the facility’s energy consumption on a net basis. Courtesy: PowerFlex |

While novel (see sidebar), linear generation technology was recommended by Lineage’s research team based in San Francisco. “We loved the technology because the emissions were just so low from natural gas generation, it was a unique unit, and it was already built out to support clean fuels in the future,” Thurston said. Linear generators were also “the only technology able to provide both dispatchability and fuel-flexibility for grid parallel operation and protection against long-duration grid outages,” he said. “I like to think of it as a better version of a battery.”

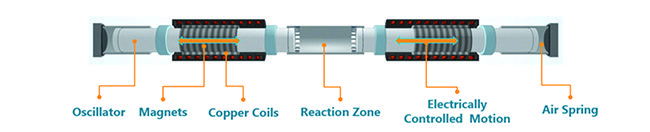

What Is a Linear Generator?Mainspring Energy’s Linear Generator is essentially an electromechanical device that directly converts motion along a straight line into power using chemical or thermal energy. More specifically, the generator uses a low-temperature reaction of air and fuel to drive magnets through copper coils to produce electricity efficiently.

According to Jim Dawe, Mainspring Energy’s chief commercial officer, a linear generator “is a new category of power generation technology delivering a major advancement in performance and flexibility.” While the Colton facility uses natural gas as its fuel, linear generators can use low-carbon fuels like hydrogen, biogas, or ammonia to produce electricity, he noted. “The product is fuel-flexible, meaning it can dynamically switch among all these fuel types without retrofit, through advanced software and power electronics. There is no other power generation technology today that can do this.” Meanwhile, the products are also “modular and scalable, and are highly dispatchable, which means they can ramp up and down to meet any load. Also, they are lower in total cost of ownership than other power generation technologies such as engines or fuel cells,” he said. |

Quick Development, Quick Completion

After Lineage separately awarded PowerFlex and Mainspring Energy turnkey contracts for delivery and construction of the rooftop solar and generator installments, the project took roughly 18 months to complete. That included three months to design the project and secure approvals from the City of Colton’s municipal utility and roughly 15 months to complete construction and begin operation. The solar array was physically completed in August 2021, and the generator project was completed with full array tie-in in December 2021.

Although the team grappled with a few setbacks stemming from pandemic restrictions, the project’s completion progressed smoothly. One reason Thurston highlighted is that Lineage found the “right utility partner” in the City of Colton. “This is a small municipality that is a little more flexible in implementing these types of solutions,” he noted. “What we found is that the utility gets to decide a lot, and they can tend to be restrictive on what kind of project you can put on their system.” Dialogue and collaboration were crucial for effective project development, he added.

And since its installation, both the rooftop array and linear generators have “performed as expected,” Thurston confirmed. The Colton facility generates 100% of its own power during the day, and its peak daytime consumption is met by about 2.5 MWac from the solar system. “About half of that is being exported from 10 a.m. to 2 p.m.,” he said. “And then as that curve starts to come down throughout the day, maybe sometime around 5 p.m. or 6 p.m.—when it stops covering 2% of our load—the generators will kick in. And then by 9 p.m., the generators will be producing half of our power needs and the other half is coming from grid.”

Crucially, reducing its non-peak demand has enabled Lineage to switch to a less-costly utility rate structure, Thurston noted. In addition, operations and maintenance of the novel facility has also been fairly straightforward given that Mainspring provided a maintenance agreement, and the solar array is owned and maintained by Madison Energy Investments, a Lineage financing partner.

First Linear Generators Deployed for Solar Firming

Lineage’s Colton project was also especially seminal for Mainspring. “Lineage was the first customer to deploy us in a solar firming scenario, where we’re firming their 3.3 MW of rooftop solar. Those are the first two linear generators in the world in a commercial deployment of this type,” Jim Dawe, Mainspring Energy’s chief commercial officer, underscored.

PowerFlex’s Ptak also hailed the project’s seamless integration. “This is the first time a PowerFlex solar PV system has paired with Mainspring technology, and this innovative collaboration signifies Chris and Lineage’s leadership in onsite renewable energy generation,” he noted. “The PowerFlex team was impressed with how easily the two technology types paired, and the PowerFlex and Mainspring teams will continue to work together on future projects for other clients,” he said.

“To summarize the essentials, it’s all about helping C&I customers reduce carbon and meet sustainability goals with lower emissions, decrease and control their energy costs, and accelerate their power delivery to be up and running quickly,” Dawe added.

Since it completed the Colton project, Mainspring has bagged several other interesting C&I projects, including accelerating electric transportation integration and biogas applications. Lineage, however, may continue to be an important customer. In May 2022, the two companies signed an agreement to deploy up to 150 linear generators across Lineage’s network of distributed facilities in the U.S. Under the agreement, the two companies may also explore the deployment of Mainspring units outside the U.S. and the use of 100% low-carbon fuels.

“This is the best kind of validation and credibility for any new technology in the power industry—satisfied customers,” Dawe said. “Equally important to us is that this deployment serves as a sort of microcosm of our vision of firming solar and wind at grid scale, being able to accelerate the transition to a zero-carbon, renewables-based grid with affordable, reliable, resilient power generation.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).