Optimizing Turbine Repair Resources

Steam turbines are used in many applications on various scales to drive equipment such as pumps, compressors, and generators. Routine maintenance, as laid out by the original equipment manufacturer (OEM) is essential for the continued reliability of machinery. In the case of steam turbines, major overhauls are required every five to eight years and the process needs to be carried out by a skilled team of engineers. Very often, the rest of the drivetrain is included in the project, which can see each piece of equipment serviced by maintenance technicians from different companies working in the same location.

Holistically Engineering the Complete Powertrain

For one power generation site in France, a recent major overhaul of a steam turbine was made far less complicated, and more cost-effective, by sourcing the necessary expertise from a single supplier. Sulzer was awarded the contract to refurbish the steam turbine, the gearbox, and the pump it was driving. The whole project needed to be completed within the six-week window of a planned outage.

Sulzer has a longstanding relationship with the power plant, being involved with the pumps at the facility for many years (Figure 1). Ahead of the scheduled outage, the site’s maintenance manager asked if the pump maintenance could be combined with the project to overhaul the steam turbine. This proposal had the potential to reduce the number of operatives working in the area and simplify project management.

|

|

1. Sulzer has a longstanding relationship with the French power plant, being involved with the pumps at the facility for many years. Courtesy: Sulzer |

Three into One Project Management

As an independent specialist in rotating equipment, Sulzer agreed to deliver the project, starting with the 10-MW steam turbine. Maxime Gheux, Buchelay Service Center Manager at Sulzer, explained, “We offered a number of benefits to the customer, not least a simplification of project management. In the past, a similar outage would have seen three separate companies involved in the project, one each for the turbine, gearbox, and pump. By taking on the combined project, Sulzer was able to offer cost savings as well as just one point of contact for the repairs.”

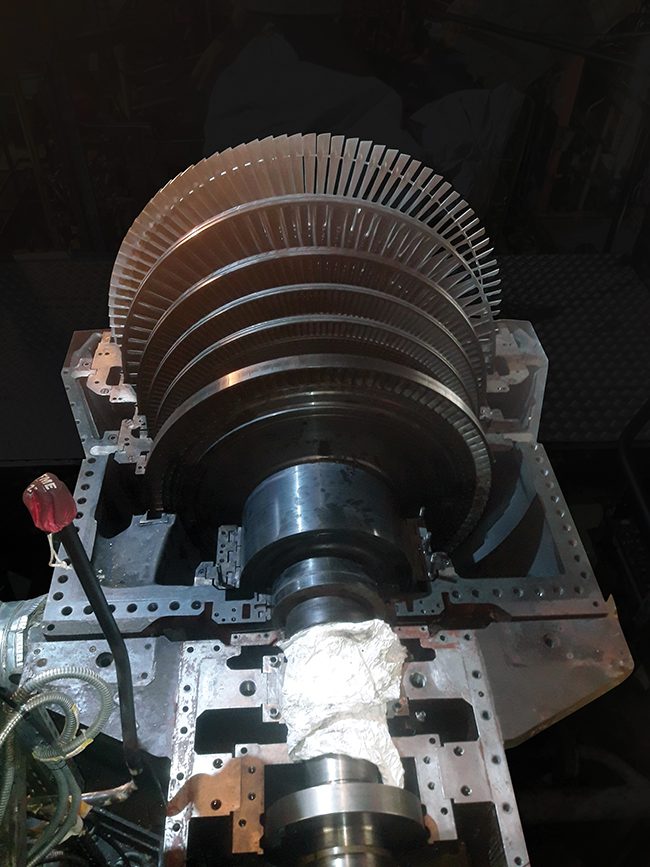

Following the first drivetrain overhaul, the customer expressed complete satisfaction in the way the project was delivered. Sulzer has since been contracted to complete two more similar projects (Figure 2). Together with the company’s proven track record of delivering rotating equipment revamp projects, the fact that Sulzer’s bid just for the turbine overhaul was 25% less than the OEM, made this an easy decision for the operator.

|

|

2. Sulzer was awarded the contract to refurbish the steam turbine, the gearbox, and the pump it was driving, all to be completed within a six-week outage window. Courtesy: Sulzer |

Bespoke Tools That Defy Maintenance Challenges

As part of the continuing partnership with the power plant, Sulzer has been creating special tools to simplify and speed up various tasks. One example is the tool to check the shaft clearance, which has been developed since the first project, and will be used along with equipment for vertically stacking the diaphragms, saving space in this congested area.

Maxime continued, “The customer is keen for us to develop more tools, especially to support the non-destructive testing (NDT) of the diaphragms and improve the handling of these components. We have considerable expertise in our global network of service centers and that can be used to benefit all of our customers.”

An Independent Service to OEM Standards

Thanks to the projects completed so far for the power plant, as well as ongoing work, Sulzer should soon receive the same qualification as an OEM. This means Sulzer would be able to complete repairs using its own facilities, documents, and expertise.

Maxime concluded, “Our knowledge of rotating equipment and our engineering expertise means that we can effectively deliver these combined projects. The field service teams work closely with our engineering departments to ensure all the necessary planning is in place to deliver a successful overhaul. Our combined skill offers power plant operators the opportunity to simplify outage management and make the project more cost-effective.”

—This article was contributed to POWER by Sulzer, a global leader in fluid engineering, specializing in pumping, agitation, mixing, separation, and application technologies for fluids of all types.