As the book title Too Dumb to Meter: Follies, Fiascoes, Dead Ends, and Duds on the U.S. Road to Atomic Energy implies, nuclear power has traveled a rough road. In…

Power

Monthly Issue | May 1, 2013

Christofer Mowry, president of Babcock & Wilcox mPower Inc. and CEO of Generation mPower LLC, a joint company of Babcock & Wilcox and Bechtel to design and build the mPower…

The Boxer-Sanders “Climate Protection Act” and its sister bill, the “Sustainable Energy Act” are the latest, and perhaps the most onerous, in a series of legislative proposals that seek to…

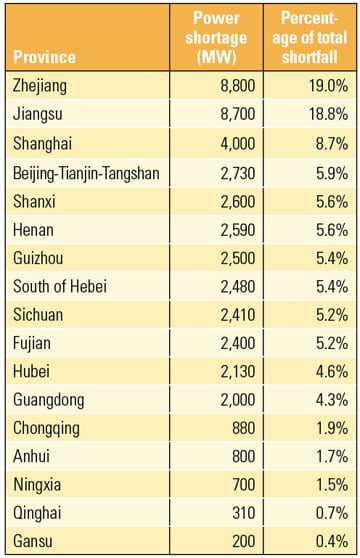

China has gone through three periods of nationwide power shortages since 1978. The previous two shortages were mostly caused by the lack of installed generation capacity. However, the third—which has…

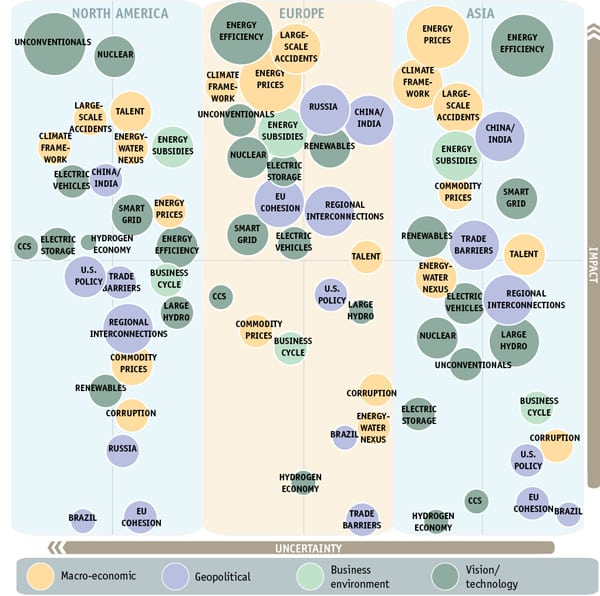

The global energy sector will need to invest half of current world gross domestic product over the next two decades in order to address a number of critical issues and…

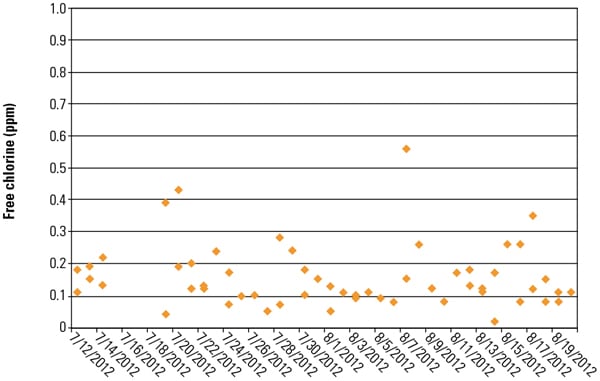

Microbial inhibition, as part of a robust cooling water treatment program, presents a special challenge because of the variability in makeup water sources, plant processes, and discharge permits. Failure to…

India’s Reliance Power in March synchronized the first of six 660-MW units of its Sasan Ultra Mega Power Plant (UMPP) in the state of Madhya Pradesh, readying it to supply…

Mexico’s Federal Electrical Commission needed a safe way to train new operators at its Laguna Verde Nuclear Power Plant in Veracruz, so it developed a stand-alone process simulator that allows…

In the U.S., where construction of new nuclear reactors has stalled for three decades, two separate nuclear projects completed placement of basemat structural concrete for new AP1000 reactors a few…

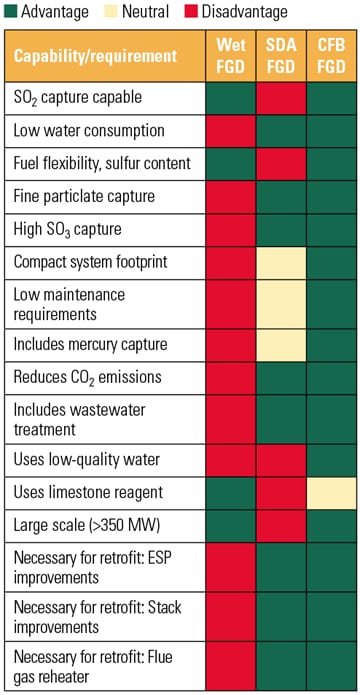

The number of regulated air emission constituents is increasing while the acceptable amounts for release are decreasing. In the long run, picking the most flexible multipollutant technology is surely the…