Chubu Electric’s Nishi-Nagoya power plant Block-1 in Japan, a plant powered by three GE 7HA turbines and Toshiba Energy Systems & Solutions steam turbine and generator technology, is officially the world’s most efficient combined-cycle power plant, according to Guinness World Records.

The entity that collects and showcases ultimate record-breaking facts highlighted the plant’s achievement of a 63.08% gross efficiency.

The recognition is monumental for GE Power, whose Bouchain plant in France established the Guinness world record for the “most efficient combined cycle power plant” in April 2016 based on its verified efficiency of 62.22%. According to Guinness, “The efficiency figure signifies the amount of energy extracted from the total combustive energy contained in the fuel.”

Bouchain, a 605-MW unit that was also a POWER magazine Top Plant in 2017, comprises the first-of-its-kind GE 9HA.01 gas turbine (and it was the first combined cycle plant equipped with an HA turbine), a D650 steam turbine, and a W86 generator working in tandem. As POWER noted, the plant can go from startup to combined cycle operation in less than 25 minutes and turned down to as low as 30% of its top generating capability while still meeting emission requirements.

GE Power on March 27 noted that the Bouchain and Nishi-Nagoya world records highlight HA turbine contributions at the world’s most efficient power plants in both the 50 Hz and 60 Hz segments.

“We’re very proud to make history once again and to partner with Chubu and Toshiba to bring GE’s industry-leading HA turbine to Japan,” said Russell Stokes, president and CEO of GE Power. “Our HA technology enables the power plant of the future, delivering unprecedented levels of efficiency and reliability that can help countries everywhere meet today’s power demands and reach more aggressive emissions goals.”

Meeting Japan’s Quest for More Efficient, Low Cost Power

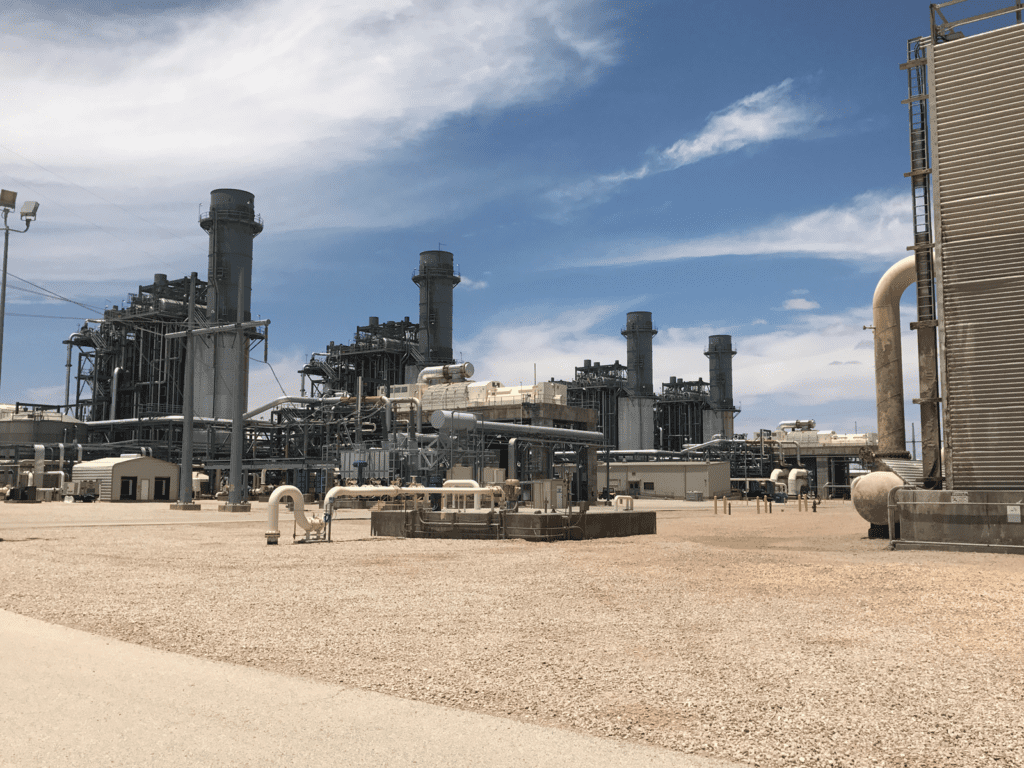

The 1.19-GW Nishi-Nagoya Block-1 began commercial operation on October 2, 2017, following years of close collaboration between Chubu, Toshiba (which served as the engineering, procurement and construction contractor), and GE to build a highly efficient thermal power plant to replace Chubu’s 40-year-old Nishi-Nagoya facility. Chubu selected the higher efficiency and more flexible large block gas turbine to could support multi-shaft (3-on-1) combined cycle operation, provide low nitrogen oxide emissions, and run on liquefied natural gas (LNG).

GE noted in a press release that the decision to build a low-cost natural gas–fired combined cycle power plant was in line with Japan’s transition to cleaner, more efficient power generation, and efforts by utilities to bolster profitability in a market characterized by more competition due to deregulation and slackened power demand.

High output and efficiency was especially important for the Chubu’s region, which is Japan’s biggest manufacturing hub. “To support manufacturing by providing a stable and inexpensive power supply in Chubu, Japan’s central region, we have been making unremitting efforts to construct power generation facilities that achieve the world’s highest levels of output and efficiency,” said Satoru Katsuno, president and director of Chubu Electric Power. “We believe that our constant quest for innovation led to this [world record] achievement.”

A Spotlight on the HA Turbine

According to GE, “HA technology was chosen as the best proven technology for the project.” HA, which is GE’s largest and most efficient gas turbine offering, has achieved more than 88,000 combined operating hours globally. The 7HA is designed to be fuel flexible, accommodating a wide range of gas and liquid fuels, including high ethane (shale) gas and LNG. The 7HA can also ramp up to full load in less than 30 minutes, allowing for greater grid stability with renewable and alternative energy sources, GE said.

GE supplied three more 7HA.01 gas turbines to Block-2 of the Nishi Nagoya facility, a unit that is expected to achieve commercial operation at the end of March 2018. GE already has two similar power plants fully commissioned in Texas that use 7HA technology. Throughout 2018, more than 30 HA units will enter commercial operation, GE said.

Meanwhile, more efficiency records may be on the horizon. In December, GE Power announced that the HA was available at more than 64% efficiency in combined cycle power plants, a milestone that it said was achieved largely due to advances in additive manufacturing and combustion breakthroughs. “Specifically, GE engineers developed additively-manufactured components for the 9HA’s combustion system, using metal 3D-printing to unlock new geometries for better pre-mixing of fuel and air, leading to greater efficiency,” it said. The new combustion system has reportedly been successfully tested at full load and full speed at GE’s test stand in Greenville, South Carolina.

GE Power, which has suffered much-publicized profitability woes owing to shaky optimism about customer gas turbine utilization amid changing electricity markets, recently embarked on a plan to keep the unit competitive. The company will continue to champion development and sales of its HA turbine offerings, however.

According to company executives, those plans include boosting the turbine’s net efficiency to 65% going out to 2025.

—Sonal Patel is a POWER associate editor (@sonalcpatel, @POWERmagazine)