As demand for electrical energy storage systems (ESS) has expanded, safety has become a critical concern. This article examines lithium-ion battery ESS housed in outdoor enclosures, which represent the most common configuration for these systems. Given the high intensity of lithium-ion battery fires, the implementation of effective fire suppression systems is essential to ensuring safety.

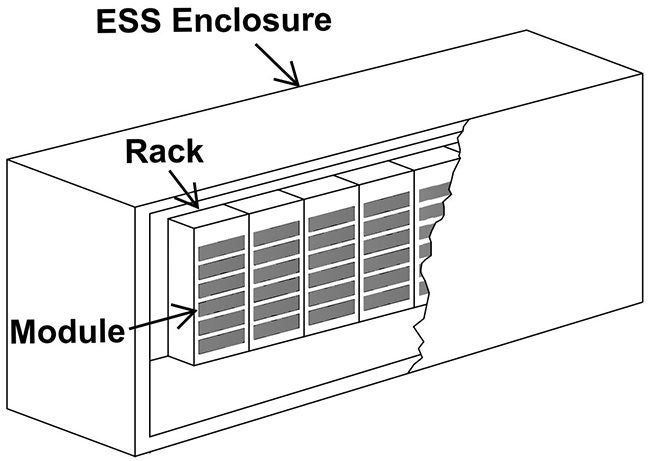

An energy storage system (ESS) enclosure typically comprises multiple racks, each containing several modules (Figure 1). These modules consist of numerous lithium-ion (Li-ion) cells, which function as rechargeable batteries designed to store and discharge electrical energy. In accordance with National Fire Protection Association (NFPA) 855 standards, ESS enclosures must be constructed from noncombustible materials and adhere to specific dimensional limits, not exceeding 16.2 meters (m) in length, 2.6 m in width, and 2.9 m in height (53 ft. x 8.5 ft. x 9.5 ft.).

|

|

1. An energy storage system (ESS) enclosure. Courtesy: CTCI |

Thermal Runaway in ESS

Thermal runaway, a process involving a series of exothermic reactions within a Li-ion battery, can trigger a fire. Thermal runaway can occur when a Li-ion battery overheats due to various factors such as internal short circuits, mechanical damage, external heating, overvoltage during charging, or failure of the battery management system. Figure 2 shows the composition of a Li-ion cell, where a separator is placed between the cathode and anode to prevent a short circuit while allowing the flow of Li-ions. The overheating can damage the cell’s separator, leading to a rapid discharge of energy, further heating, and the release of combustible electrolyte. This electrolyte emits flammable and toxic gases, which can ignite and cause deflagration.

|

|

2. The composition of a lithium-ion cell. Courtesy: CTCI |

Thermal runaway can spread from a single cell to an entire module, rack, or even the entire enclosure, making the selection of an appropriate fire suppression system critical for the safety of ESS installations. Two commonly referenced standards for ESS fire suppression systems are FM Global Data Sheet (FM DS) 5-33 and NFPA 855.

In the event of thermal runaway, it is essential to rapidly cool the affected module and its surroundings to prevent a chain reaction of battery fires. Without adequate cooling, batteries can reignite, even after the initial fire is suppressed. For this reason, both FM DS 5-33 and NFPA 855 mandate the use of automatic sprinkler systems for ESS fire suppression.

NFPA 855 also permits the use of alternative fire suppression systems if they successfully pass large-scale fire testing in accordance with Underwriters Laboratories (UL) 9540A, “Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems,” or an equivalent standard. To meet this requirement, the test results must demonstrate that a fire involving one ESS rack will not propagate to adjacent racks. UL 9540A, specifically the Installation Level Test, Method 2, provides critical data to evaluate the suitability of alternative fire suppression systems for ESS applications. UL 9540A outlines the procedures for assessing the safety, performance, and reliability of battery ESS.

Another relevant standard is UL 9540, “Safety of Energy Storage Systems and Equipment,” which addresses the requirements for mechanical safety, electrical safety, fire safety, thermal safety, system performance, system reliability, and system documentation. UL 9540 is accredited by the American National Standards Institute (ANSI), and NFPA 855 requires most ESS equipment to be listed in accordance with UL 9540.

According to FM DS 5-33, the minimum separation distance between adjacent ESS enclosures with noncombustible walls should be 6 m to prevent fire from spreading between them. Where space is limited, a thermal barrier rated for at least one hour must be installed between enclosures. A concrete masonry unit can serve as an effective thermal barrier.

Fire Suppression Systems

This section explores three common fire suppression systems for outdoor ESS enclosures: automatic sprinklers, water mist, and gaseous suppression systems. Their respective advantages and limitations will be compared.

Automatic Sprinkler System. Sprinkler systems are the preferred method for protecting ESS due to their superior cooling capabilities, low cost, human safety, and environmental friendliness. While the rack frame may obstruct direct water flow to the cells, sprinklers can still effectively prevent a fire from spreading to adjacent racks. However, it is important to consider that sprinklers may cause water damage following discharge.

Lithium-iron-phosphate (LFP) and lithium nickel manganese cobalt oxide (NMC) are two common types of lithium-ion batteries. According to a June 2019 research report titled “Development of Sprinkler Protection Guidance for Lithium-Ion Based Energy Storage Systems” by FM Global, the minimum sprinkler density required for ESS is 12.2 liters per minute per square meter (Lpm/m2), or 0.3 gallons per minute per square foot (gpm/ft2), for both LFP and NMC batteries.

The report indicates that ESS systems using NMC batteries pose a greater fire risk than those with LFP batteries, and it provides guidelines for the required separation between racks and the necessary sprinkler discharge duration. For LFP batteries with sprinkler protection, the minimum separation is 0.9 m (3 ft.) from non-combustible objects and 1.5 m (5 ft.) from combustible objects. The discharge duration must be at least 90 minutes. Meanwhile, for NMC batteries with sprinkler protection, the minimum separation is 1.8 m (6 ft.) from non-combustible objects and 2.7 m (9 ft.) from combustible objects. Discharge duration for NMC batteries is 45 minutes multiplied by the number of adjacent ESS racks, that is, racks with less than the recommended separation for combustible objects, but no less than 90 minutes.

FM DS 5-33 adopts the stricter NMC requirements for separation distances and discharge durations, regardless of whether LFP or NMC batteries are used. FM-approved fire barriers can be installed between racks to reduce water demand. NFPA 855 specifies the same sprinkler density as FM DS 5-33 but allows for the use of an alternate density if supported by large-scale fire testing in accordance with the UL 9540A Installation Level Test, Method 1.

For a standard 40-foot enclosure with dimensions of 12.2 m (length) x 2.44 m (width), the minimum required water flowrate and capacity are calculated as follows. Flowrate = 12.2 m x 2.44 m x 12.2 Lpm/m2 = 363.2 Lpm. Capacity = 363.2 Lpm x 90 min = 32,688 L (32.688 m3).

Water Mist System. A water mist system, similar to sprinklers, uses water but at high pressure to create a fine mist with droplets smaller than 100 microns in diameter. This mist vaporizes into steam, expanding more than 1,700 times in volume. Water mist suppresses fires by cooling the cells, reducing oxygen concentration, lowering radiant heat transfer, and inhibiting the exothermic reactions associated with thermal runaway.

Water mist systems are categorized by pressure into three types: Low pressure (less than 12.1 bar [175 psi]), intermediate pressure (12.1 bar to 34.5 bar [175 psi to 500 psi]), and high pressure (greater than 34.5 bar [500 psi]). NFPA 855 requires compliance with NFPA 750 for water mist systems. According to NFPA 750, the system must provide sufficient flow to meet the nozzle’s discharge density rating, with a minimum discharge duration of 30 minutes. For typical mist nozzles, the required water density ranges from 1.0 to 2.0 Lpm/m2. For a standard 40-foot enclosure, the estimated minimum flowrate and capacity are calculated as follows. Flowrate = 12.2 m x 2.44 m x 2.0 Lpm/m2 = 59.5 Lpm. Capacity = 59.5 Lpm x 30 min = 1,785 L (1.785 m3)

Please note that these figures represent minimum requirements. The actual flowrate and capacity should be verified through large-scale testing to ensure that battery temperatures are reduced below the auto-ignition point and the threshold for triggering thermal runaway.

Compared to sprinkler systems, water mist systems offer several advantages, including lower water consumption and smaller pipe sizes, which facilitate easier installation in confined spaces. Additionally, the fine mist reduces the risk of equipment damage.

Gaseous Suppression System. Common agents used in gaseous suppression systems for ESS include inert gases and FK-5-1-12 (NOVEC 1230). Inert gases function by lowering the oxygen concentration to suffocate the fire and are environmentally friendly. In contrast, FK-5-1-12 interrupts the fire’s chemical reaction rapidly. Both agents minimize damage to electrical equipment since they do not pose a risk of short circuits, leave no residue, and require minimal cleanup. To reduce downtime due to replenishment delays, the gas reservoir should be sized to accommodate two discharges. Ensuring proper airtightness in the enclosure is crucial to prevent gas leakage. NFPA 855 mandates compliance with NFPA 2001 for the use of inert gases and FK-5-1-12.

However, FM DS 5-33 does not recommend gaseous suppression systems for ESS due to their limited effectiveness, lack of cooling, and potential for reignition. Therefore, a combined suppression system may be employed. In the initial stage of temperature rise, the electrical circuit should be cut off, and the gaseous suppression system activated to resist thermal runaway. If this fails, a water-based suppression system can be activated to fully extinguish the fire.

Weighing the Pros and Cons

This study presents key findings and recommendations for selecting fire suppression systems for ESS in outdoor enclosures. FM DS 5-33 and NFPA 855 are recognized standards for the design and installation of these systems.

A thorough analysis of three common fire suppression systems was conducted. The research suggests the system with the highest suppression effectiveness typically uses the most water and may cause the greatest damage to equipment. Still, the pros of these systems often outweigh the cons. It is important to note, however, that these rankings are general; each system’s suppression effectiveness and water requirements may vary based on individual manufacturer designs.

To enhance safety, enclosures should be equipped with vents to facilitate gas release and prevent accumulation. Since deflagration can occur even in the presence of fire suppression systems, the installation of deflagration vents at the top of the enclosure, compliant with NFPA 68, can help mitigate the risk of enclosure rupture during such events.

—Yung-Shun Yen and Kuan-Hung Chen are industry experts with CTCI Corp.