Instrumentation & Controls

-

Instrumentation & Controls

Power Plant Automation: Where We Are and Where We’re Headed

Over the past decade, power plant control systems have evolved from DCS-centered platforms with proprietary software, to open systems using industry standard hardware and software, and then to totally integrated plant automation systems with almost unlimited connectivity and the ability to interrogate field instruments from many different manufacturers. What’s next?

-

Instrumentation & Controls

Enhancing Plant Asset Management with Wireless Retrofits

Wireless technology is a mostly untapped resource in the power generation industry that can have a significant impact on the way business is done. It enables a greater degree of connectivity among devices for enhanced monitoring and asset utilization and has led to the development of new applications that improve productivity, uptime, and overall business performance.

-

Instrumentation & Controls

Wireless Technology Unlocks Possibilities

Modern wireless systems improve productivity, monitoring activities, and safety at power plants by enabling the right people to be at the right place at the right time. Wireless technology can put hard-to-access process and asset information at your fingertips, wherever you are, to enable more accurate and timely decisions.

-

Instrumentation & Controls

Upgraded Control System Adds to Merchant Plant’s Bottom Line

If the rotating equipment and boiler are a plant’s brawn, then a control system that efficiently integrates myriad plant functions is its brains. Luckily, in a power plant, we can perform a brain transplant when the control system becomes unreliable or too costly to maintain. But first, you have to justify that surgery.

-

O&M

JCP&L’s SCADA-controlled adaptive relay scheme saves 25 SAIDI impact minutes

In 2005, Jersey Central Power & Light (JCP&L), a subsidiary of Akron, Ohio – based FirstEnergy Corp., initiated a project to identify protection system improvements that could be made to proactively combat wind- and lightning-related weather events that create sustained power outages (Figure 2). JCP&L determined that these changes had the potential to improve the […]

-

O&M

Entergy’s “big catch”

Entergy christened its Performance Monitoring and Diagnostic Center several years ago to leverage the expertise of its most senior operators and technicians across the company’s entire fleet of plants. The center also makes use of advanced software tools that increase plant availability and reliability by identifying faults before they become major, unplanned outages. The center paid for itself for years to come with a single “big catch” last year.

-

O&M

Focus on O&M (September 2008)

Tackling substandard water sources / Control abrasive wear in scrubber piping / Sensors and final control elements

-

Instrumentation & Controls

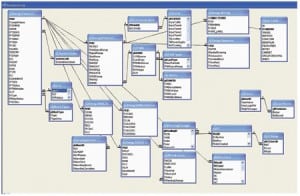

Digital technology spawns need for configuration management

Documenting changes to the distributed control system and other digital plant applications should be considered a critical element of managing risk—and of safe, efficient daily operations and maintenance. Coming up with a practical configuration management approach, though, isn’t easy.

-

Instrumentation & Controls

Assessing and addressing cyber threats to control systems

Control systems used by utilities and other operators of America’s industrial infrastructure increasingly rely on an Internet connection that makes them as vulnerable to hackers as any computer or network. One reason many utility control systems are vulnerable is that, unlike your ISP’s systems, they don’t record an audit trail that reveals the source of the attack.

-

O&M

Boiler optimization increases fuel flexibility

Burning spot market fuels can reduce plant fuel costs, but it can also introduce unexpected operational problems throughout the boiler island. Orlando Utilities Commission’s Stanton Energy Center optimized its Unit 2 combustion system and improved O&M practices as part of a project to increase the unit’s fuel flexibility without degrading reliability or heat rate. OUC’s attitude: If you can measure it, you can manage it.