China has been battling—and losing—a “war” on air pollution for years. Stepping up its efforts, the country recently issued new policy measures, tougher even than those in the U.S. and…

Coal power plant design, construction, operation and maintenance, as well as legal and regulatory issues.

China has been battling—and losing—a “war” on air pollution for years. Stepping up its efforts, the country recently issued new policy measures, tougher even than those in the U.S. and…

Even without regulatory considerations, there are good reasons for virtually every coal-fired power plant to improve its heat rate. The Electric Power Research Institute (EPRI) has looked at dozens of…

The first full-scale commercial post-combustion carbon capture and sequestration (CCS) project at an operating coal-fired power plant is now online in Estevan, Saskatchewan, roughly 10 miles north of the U.S.…

![Plant Washington Coal Project Gets Permit Extension [Updated]](https://www.powermag.com/wp-content/uploads/2014/02/Stock_ColoCoalTrain_feb2014_GReitenbach_Web.jpg)

Plant Washington, a planned $2.1 billion, single-unit, 850-MW supercritical coal plant that a consortium of generators has been trying to build near Sandersville in east-central Georgia, was given an 18-month…

Cost estimates for the Kemper County Integrated Coal Gasification Combined Cycle project (IGCC) have surged another $330 million since August, mostly owing to delays that have shifted the plant's in-service…

The U.S. Environmental Protection Agency (EPA) has released a notice of data availability (NODA)—making additional information and ideas available for public comment—and it has also proposed carbon goals for areas…

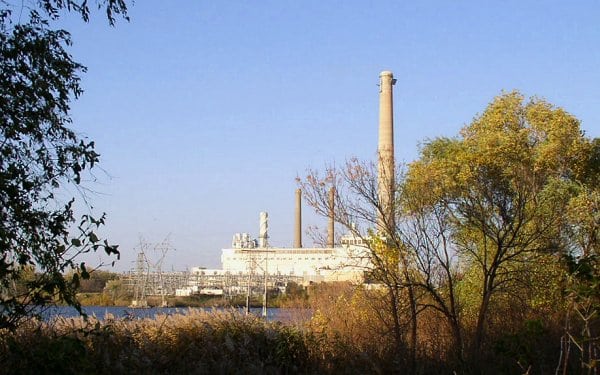

Xcel Energy formally notified state regulators and the Midcontinent Independent System Operator that it plans to close the two remaining coal-fired units at its Black Dog Generating Station in Burnsville,…

Plant engineers at Eskom’s Majuba Power Station in South Africa have been continuously looking for ways to improve efficiency and reliability. The six-unit, 4,000-MW, supercritical coal-fired plant was experiencing an…

San Antonio's CPS Energy on Monday announced a new agreement to buy power from Summit Power's proposed integrated combined cycle coal gasification (IGCC) plant that will include carbon capture, utilization,…

American Electric Power's (AEP's) Ohio unit has asked the state's Public Utilities Commission for permission to essentially charge customers for costs to operate nine unregulated coal-fired units, a move the…