Though unsigned by its governor, North Carolina has enacted the nation's first comprehensive coal ash management law. The statute, which took effect on Sept. 20, applies to all unlined dry…

Coal power plant design, construction, operation and maintenance, as well as legal and regulatory issues.

Though unsigned by its governor, North Carolina has enacted the nation's first comprehensive coal ash management law. The statute, which took effect on Sept. 20, applies to all unlined dry…

With Units 6 and 7 back in operation, Colorado Springs Utilities (CSU) has restored 80% of the generation capacity at its Martin Drake Power Plant located in downtown Colorado Springs.…

Consumers Energy—Michigan’s largest utility—reached an agreement with the U.S. Environmental Protection Agency (EPA) and the U.S. Department of Justice that will result in more than $2 billion being spent on…

Power companies will retire more coal-fired generating capacity and retrofit much fewer units with environmental controls than estimated just two years ago, the Government Accountability Office (GAO) reveals in a…

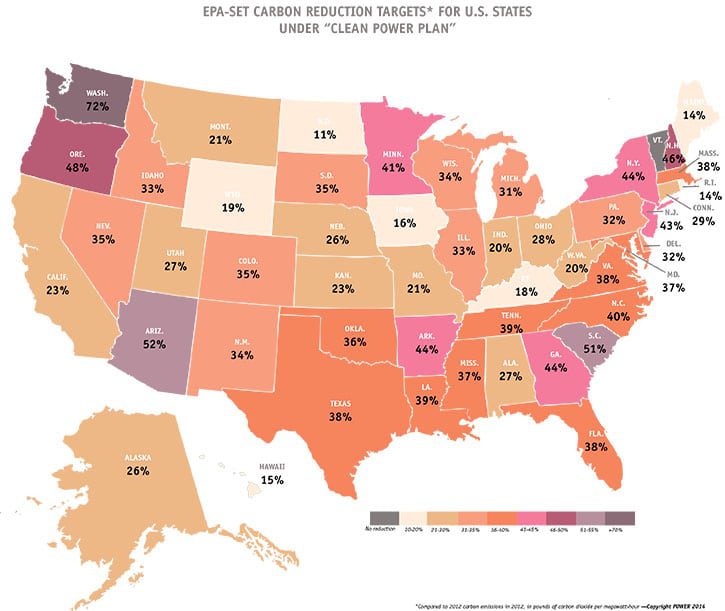

The Environmental Protection Agency (EPA) has extended the public comment period for its proposed rule to limit carbon dioxide emissions from existing power plants by 45 days. Janet McCabe, acting…

Regulators from six states shared starkly different views on the Environmental Protection Agency's (EPA's) proposed carbon rules for existing power plants at a House hearing on Tuesday. Some state-level officials…

The coal supply picture for Midwest power plants darkened again this summer as deliveries of Powder River Basin (PRB) coal to the region fell for a second consecutive quarter due…

The Environmental Protection Agency (EPA) on Tuesday granted the nation's first four Class VI underground injection permits for carbon sequestration to the federally backed FutureGen 2.0 carbon-capture-and-storage (CCS) project. The…

Revised national ambient air quality standards (NAAQS) for ozone that are expected from the Environmental Protection Agency (EPA) this December will likely be stricter. Agency staff from the Office of…

The Aug. 4–6 U.S.-Africa Leaders Summit shed light on the power plights faced by sub-Saharan African countries, but it also highlighted their massive power potential and the array of solutions…