Coal

-

Coal

Speaking of Coal Power: Illinois Coal Poised for Comeback

Sylvester Stallone, as Rocky Balboa, staged another magical comeback earlier this year — in the ring and at the box office. Just when you think Rocky is down and out for good, the sixth release of the Rocky franchise just may be the best of the lot. "Down but not out" is also an apt […]

-

Coal

The Coal Patrol: Coal-to-Liquids Resurfaces after 20 Years

It’s déjà synfuels all over again. With crude oil prices seemingly interminably pegged at over $60 a barrel, the old, beguiling notion of turning coal into liquid fuel — a task accomplished by the Nazis in the 1940s and the South Africans in the 1970s and 1980s — is once again front-page political news in […]

-

Coal

PRB Tech Notes: Pay Me Now or Pay Me Later

Money is always spent with the best intentions. We look for the best deal, often identifying it by the lowest price. Sometimes, our choice works out and we save money and get a great product. When it doesn’t work out, however, we find ourselves spending more and more money to repair or replace our "great […]

-

O&M

Coal Plant O&M: River Locks and Barges Are an Aging Workforce, Too

During 2005, about 150 million tons of coal were transported to power plants by hopper barges plying U.S. inland waterways. With coal-fired plants expected to continue producing 50% of America’s electricity, coal barge traffic is not likely to fall off. In fact, it may increase, for two reasons. One is cost. Shipping coal by barge […]

-

O&M

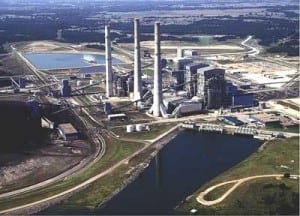

Pollution Control: LCRA Fayette Lowers NOx Below 0.10 lb/mmBtu

The Fayette Power Project (FPP, aka the Sam K. Seymour Power Station) is a three-unit, coal-fired generating plant sited near La Grange, Texas (Figure 1). Units 1 and 2, each with a nominal rating of 600 MW, are co-owned by the Lower Colorado River Authority (LCRA) and Austin Energy (AE). LCRA is a conservation and […]

-

O&M

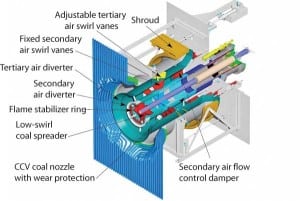

Pollution Control: Low-NOx Combustion Retrofit Options

Reducing NOx emissions from large utility coal-fired boilers has been a primary focus of the U.S. power generation industry since passage of the 1970 Clean Air Act and subsequent legislation. By the early 1990s, nearly all such boilers had installed some form of low-NOx burner (LNB) technology and/or overfire air (OFA) — the least expensive […]

-

Coal

The Coal Pile

Ninety years ago America was at war, and producers of coal (principally anthracite) were struggling to meet demand. It’s hard now to conceive of coal as the universal fuel, but there was a time when it was used in the U.S. to heat homes, schools, and libraries as well as to make steel and manufacture […]

-

Coal

Global Monitor (April 2007)

Npower plans big coal plant in UK / Berkeley boffins make thermoelectric discovery / Rinspeed’s roadster: Fast, fun, and green / Dead chickens, the weirdest renewable / Siemens celebrating three big deals / Nevada Power picks P&W, CH2M Hill / Scuderi’s air-hybrid engine / Ovation for huge new Chinese coal plant / PG&E dips toe into wave power / POWER digest

-

Coal

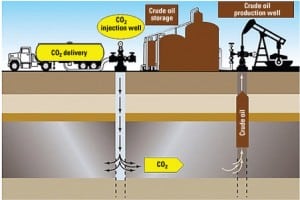

Exploring the many carbon capture options

Carbon capture and sequestration have many technical hurdles to leap in coming years. The capture and reuse of CO2 to enhance oil recovery preceded the current clamor over climate change, and that experience is often used as an example that the process is a viable way to handle this greenhouse gas. This article explores options for the first part of the process: CO2 separation and capture.

-

Coal

At CERA Week 2007, most life was carbon-based

For the past 25 years, Cambridge Energy Research Associates has hosted an annual conference that has drawn the captains of the worldwide oil and gas and electricity industries. The 120 distinguished speakers at this year’s summit attracted more than 2,000 delegates from 55 countries, making it the largest and most diverse ever. Naturally, one of POWER’s contributing editors was there, too; here’s his take on what transpired.

-

O&M

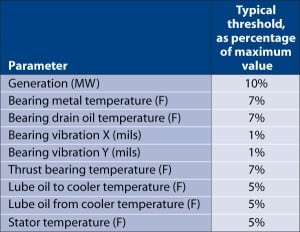

Coal Plant O&M: Continuous On-line Monitoring Cuts Downtime, Costs

As gencos seek to improve plant reliability and availability, many are turning to on-line condition monitoring for help. Huge advances in the capabilities of on-line diagnostics have occurred over the past five years. By using this technology, plant personnel can spot early warning signs of impending equipment failure and take action to correct the underlying […]

-

Coal

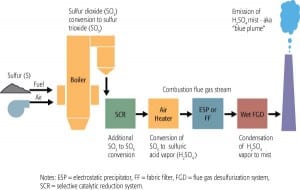

SO3 Control: AEP Pioneers and Refines Trona Injection Process for SO3 Mitigation

Using a selective catalytic reduction (SCR) system to reduce the emissions of nitrogen oxides (NOx) from a coal-fired power plant is rapidly becoming the norm, rather than the exception. But for many plants, adding an SCR system has unintended consequences: greater oxidation of sulfur dioxide (SO2) to sulfur trioxide (SO3), and a rise in stack […]

-

O&M

SO3 Control: Dominion Demonstrates CleanStack Technology

Dominion Generation (DG) has installed selective catalytic reduction (SCR) systems on many of the large coal-fired generating units it operates. The catalyst used has an SO2 to SO3 oxidation rate of about 1%, which roughly doubles the SO3 concentration at the outlet of the boiler economizers. The magnitude of the increase was proportional to the […]

-

O&M

SO3 Control: How Many Coal Plants Might Have Opacity Issues Due to SO3 Emissions?

Flyash and condensed sulfur trioxide (SO3) are the major components of flue gas that contribute to the opacity of a coal plant’s stack emissions (stack opacity). Estimates are that 75% to 85% of bituminous coal-fired plants with selective catalytic reduction (SCR) and/or wet flue gas desulfurization (FGD) systems are likely to produce enough SO3 vapor […]

-

Coal

The Coal Pile

This month’s photo was submitted by David Carter, power generation supervisor at Springerville Generating Station. Readers of POWER may recall that Springerville Unit 3 — the first pulverized coal – fired unit built in the U.S. in more than a decade — was that magazine’s 2006 Plant of the Year. Located in northeastern Arizona, the […]

-

O&M

Speaking of Coal Power: Coal in a Carbon-Constrained World

Carbon capture and sequestration (CCS) have elbowed their way into the nation’s lexicon with the rise in concern over climate change. But few of the journalists who are hyping global warming have taken the trouble to learn the ins and outs of producing affordable electricity from coal. Citizens of the industrialized world now wring their […]

-

Coal

The Coal Patrol: Glaciers and New Coal Plants

The big buzz still echoing through world of coal-fired generation is the move by two big-bucks private equity investors to take TXU Corp. off the public market, including scuttling announced plans for eight new pulverized coal – fired plants. That leaves alive plans for three new units at TXU’s existing Sandow and Oak Grove sites. […]

-

Coal

PRB Tech Notes: New Plant/Old Plant: Are We Applying What We’ve Learned?

In the last issue of COAL POWER, I urged readers to give coal handling the priority it deserves. The coal yard warrants as much attention as boilers and combustion systems, turbine-generators and auxiliaries, and postcombustion emissions control — the other three "zones" within the plant perimeter — because it is an equally valuable business unit. […]

-

O&M

To optimize performance, begin at the pulverizers

A systematic, performance-driven maintenance program for optimizing combustion can achieve great results. The challenge for an O&M staff is deciding which proven strategy and tactics for reducing NOx and improving plant reliability to adapt and implement. The structured approach presented here has proven its worth at several plants that have wrestled with problems similar to yours.

-

O&M

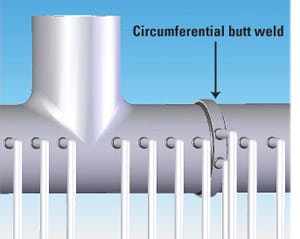

Finding and fixing cracks in high-temperature headers

The welds on superheater and reheater headers are arguably the most stressed parts of a modern steam plant. For that reason, it’s surprising that they also may be the most under-inspected. Cracks are rare, but they can be repaired if found early. One plant avoided a long forced outage to replace a reheater outlet header by using the correct condition assessments and welding techniques.

-

O&M

SO3’s impacts on plant O&M: Part II

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operation and maintenance of back-end plant equipment. In this issue, we list and quantify the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. Part III—to appear in the April 2007 issue—will describe the characteristics of an optimal SO3 removal technology and present the technical details and operating experience of one patented process that has worked successfully at a half-dozen plants for up to three years.

-

Coal

Sealing abandoned mines with treated flyash kills two birds with one stone

Environmentally benign disposal of coal combustion products/by-products (CCPs) such as flyash and bottom ash has been a problem since the first coal-fired power plant went on-line. In recent years, ways have been developed to recycle CCPs into useful commercial products like bricks and roadbase. This article describes an innovative State of Maryland program that is putting CCPs to yet another use: stabilizing abandoned mines to permanently sequester acids and harmful metals.

-

Coal

NOx, SO3 in the spotlight at NETL’s 2006 Environmental Controls Conference

As emissions caps drop, technological solutions must become increasingly effective and efficient. Researchers, equipment vendors, and plant operators are exploring alternatives to SCR and SNCR, with a view to reducing the overall costs of NOx reduction. They’ve also achieved 95% to 99% removal of SO3, with no visible plume opacity.

-

Coal

Global Monitor (January 2007)

DOE walks the clean coal talk / For Swedish nuke, a case of mistaken identity / Siemens completes big CHP plant / E.ON bets big on coal / BP Solar expands Maryland plant / GE scores big turbine deals / PSNH switches from coal to wood / EPRI tests solid-state current limiter / POWER digest

-

Coal

Investment in generation is heavy, but important needs remain

Forecasting the direction of the U.S. electric power industry for 2007, much less the distant future, is like defining a velocity vector; doing so requires a direction and speed to delineate progress. In this special report, POWER’s first stab at prognostication, the editors look at current industry indicators and draw conclusions based on their more than 100 years of experience. To borrow verbatim the title of basketball legend Charles Barkley’s book: I May Be Wrong but I Doubt It.

-

Coal

Near-term capital spending in the North American power industry

Following the money invested in projects is a viable way to compare growth trends for power projects using the four major generation types: coal, natural gas, nuclear, and renewable.

-

Coal

Speaking of Coal Power: Shedding More Heat Than Light

When Charles Dickens began A Tale of Two Cities with, "It was the best of times, it was the worst of times," he was referring to the French Revolution of the late 18th century. But Dickens’ words apply equally well to the American generation industry of the late 20th century. A decade of overbuilding U.S. […]

-

O&M

The Coal Patrol: Looking Back at 2006

To borrow shamelessly from Charles Dickens, one of my favorite authors, for coal in 2006, "It was the best of times, it was the worst of times." No Escape The year began in horror. On January 2, most likely a result of a severe lightning strike, methane gas in the International Coal Group’s Sago Mine […]

-

Coal

PRB Tech Notes: Give Coal Handling the Priority It Deserves

Over the past 17 years — dating back to the 1990 Clean Air Act Amendments and including the introduction of retail competition — coal-fired power plants have become much cleaner and more efficient. Utilities have spent many billions of dollars to install pollution controls for regulatory reasons, and only slightly less to upgrade turbine-generators and […]

-

O&M

Coal Plant O&M: Elemental Analyzer Checks Quality of Delivered Coal in Real Time

When you receive a shipment, you don’t wait weeks to see whether you got what you paid for — do you? J.M. Stuart Generating Station doesn’t, but it used to. Since coming on-line in the early 1970s, the big plant, on the Ohio River near Aberdeen, Ohio, mechanically sampled coal shipments as they reached the […]