|

A diesel-powered rotary flywheel is at the heart of an innovative backup power system for the campus at the University of Washington.

The University of Washington needed to bring new life to its 1960s-era steam plant. Campus officials knew the priority for an upgrade would be a system with the ability to provide uninterrupted power during outage events.

Mark Kirschenbaum, the assistant director of campus utilities, noted the importance of backup power, and also the challenges faced with improving the decades-old plant. “It could be just a five-second loss of power, but it’s a five-hour recovery period,” said Kirschenbaum of dealing with the aging facility. The solution would be found with a system used by data centers, but one that had rarely been deployed on a college campus.

Stanley Consultants, known for its engineering expertise, created an extensive matrix to evaluate the feasibility of all possible options for upgrading the power plant. It was decided a Diesel Rotary Uninterruptible Power Supply, or DRUPS, system (shown above)—manufactured by HiTec, with an expected lifespan of 35 years—was the most economical and efficient option.

“Multiple options were considered when determining which type of system would work best for the University of Washington, including batteries, fuel cells, renewables, heat pumps, sewer waste heat recovery, electric boilers, combustion turbine/microturbine, and more,” said John Solan, principal mechanical engineer with Stanley Consultants. “The DRUPS was selected because it provided the plant with necessary electrical reliability while lessening the university’s reliance on fossil fuel technologies. Relying on the DRUPS instead of a larger steam turbine simplified the plant’s high-pressure steam system and reduced fossil fuel consumption.”

The existing steam turbine was decommissioned and replaced with the DRUPS. Officials said the upgrade proved its usefulness just weeks after commissioning, and has been utilized many times since coming online. The project was substantially completed in January of last year, at a total cost of $27 million.

“From an operational standpoint, the DRUPS functions the same for a university as it does for a data center. The DRUPS identifies issues with the incoming electrical feed within milliseconds and instantaneously responds to enable a continuous supply of power to the user,” said Solan. “While the DRUPS unit itself would be the same for a data center or a university, there are differences in the configuration of the supporting electrical equipment. This is primarily due to the need to integrate the DRUPS equipment into an existing campus electrical distribution system. Stanley Consultants conducted a thorough design process to confirm the DRUPS was properly integrated into the campus electrical system and could be operated safely.”

Officials said UW is thought to be one of only a few campus sites in the U.S. to utilize the DRUPS system. The equipment is essentially a six-ton flywheel, continuously spinning at more than 4,200 revolutions per minute (RPM), which keeps the campus power plant operating when the electricity supply to the university is disrupted. If the outage is more than a few milliseconds, the diesel engine kicks in and maintains the power supply, resulting in no interruption to electricity service.

The DRUPS also has a side benefit from the rotational mass—increased voltage support in the electrical system. The new power plant’s value to the campus makes it a worthy recipient of POWER’s 2025 Reinvention Award.

Critical Need for Reliable Power

Reliable power is essential to the university, and certainly to the campus hospital. A loss of energy, and therefore steam, could result in canceled surgeries, an inability to sterilize instruments, and potentially ruin scientific experiments.

“The earlier plant could not be trusted to provide uninterruptible power. The aging steam turbine was becoming increasingly unreliable, leading to large repair expenses and unacceptable downtime,” said Kirschenbaum. “The University of Washington needed a guaranteed supply of uninterruptible power for its central heating plant. With a steam boiler, a brief sag in power can result in an hours-long recovery. In fact, a one-second interruption of power can result in a four-hour recovery period to bring the plant back up. Due to critical heat loads, such as the UW hospital, such outages were not acceptable.”

Kirschenbaum said Seattle City Light serves the main campus electrical load. During the construction phase for the upgraded system, the power plant’s emergency power needs were temporarily covered by a diesel generator, which provided backup power until the DRUPS system became operational.

Officials said the project was completed on budget, thanks to the progressive design-build engineering, procurement, and construction contract that contained multiple risk contingencies that ultimately were not needed, largely due to the team from McKinstry, an engineering and design group. The released contingencies allowed the university to increase the scope of the project, using those funds to update other critical plant needs, including emissions monitoring and replacing old valves.

Kirschenbaum said a common thought among utility managers looking to reduce emissions is to get rid of an old plant that burns fossil fuel. Officials at UW, though, understood that an aging plant could be modified to reduce carbon emissions significantly, and plant operators could rework the old equipment while taking regular steps toward the future—and do it economically.

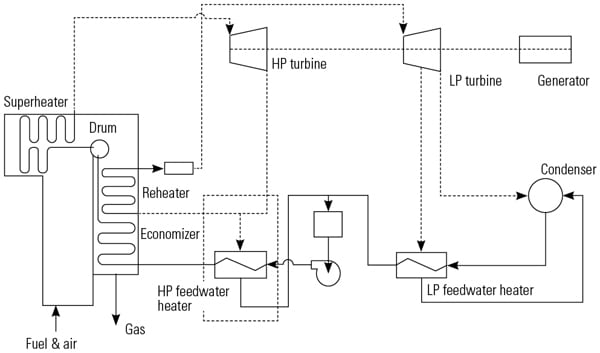

Kirschenbaum said, “For decades, the University of Washington’s steam plant, formerly powered by coal but now by natural gas [with diesel as a backup fuel], operated with two different steam systems—425 psig superheated and 185 psig saturated. The 425-psig system was comprised of an Erie City Iron Works and Foster Wheeler boilers with a total capacity of 450,000 pph [pounds per hour of steam]. The 185-psig system was comprised of two Riley Stoker and one Foster Wheeler boilers totaling 430,000 pph of capacity.

“The boiler installation dates range from 1948 to 2000,” said Kirschenbaum. “Removing the 1968 5-MW Worthington steam turbine eliminated the need for the superheated system. This made it possible to reduce the operating pressure of the two superheated boilers to 185 psig saturated steam by removing the superheater, modifying boiler tubes, and replacing the steam drum internal equipment to match the lower operating pressure.

“The old facility was not demolished but rather retrofitted to accommodate the new DRUPS and boiler modifications. McKinstry began work onsite April 2022, modifying the steam piping and preparing the DRUPS site. The DRUPS arrived in September 2022 and was placed into service in November 2022,” said Kirschenbaum. “From summer 2022 through 2023, modifications were made to the two superheated boilers converting the plant to 185 psig saturated steam only. Project scheduling ensured that all plant boilers were available during the winter heating season. The plant also took the opportunity to replace the 30-year-old continuous emissions monitoring system [CEMS]. CEMS certification testing was completed in November 2023, and the project was substantially completed in January 2024.”

|

|

1. The new 3-MW steam turbine is a single-stage, backpressure unit, using 185 psig saturated steam and reducing it to match the 10-psig campus heating system. Courtesy: Stanley Consultants |

Officials said a 3-MW backpressure steam turbine (Figure 1), specifically made for saturated steam, was added to the design to recover energy when reducing steam pressure down to the 10-psig steam distribution system. According to Kirschenbaum, eliminating superheated steam not only simplified plant operations but also reduced the fuel consumption by more than 10%, which also reduced carbon emissions.

Integration and Synchronization

Demolition of the old plant, and construction of the new facility, was challenging due to its location on a hillside. Finding an accessible, sufficient site that could bear the load of the 30-ton high-mass, high-speed DRUPS in a seismic zone required a reinforced foundation that was reverse engineered. Another challenge was to modify, meld, and integrate a 60-year-old legacy system with new components—instrumentation, controls, software, sensors, relays, and switchgear—so that the old interfaced and synchronized with the new. The group worked with the two original boiler manufacturers to gather information on how to best manually remove the superheater tubes from those boilers. Extensive modifications were made to the decades-old switchgear and relays to synchronize with the new system.

Demolition of the old plant, and construction of the new facility, was challenging due to its location on a hillside. Finding an accessible, sufficient site that could bear the load of the 30-ton high-mass, high-speed DRUPS in a seismic zone required a reinforced foundation that was reverse engineered. Another challenge was to modify, meld, and integrate a 60-year-old legacy system with new components—instrumentation, controls, software, sensors, relays, and switchgear—so that the old interfaced and synchronized with the new. The group worked with the two original boiler manufacturers to gather information on how to best manually remove the superheater tubes from those boilers. Extensive modifications were made to the decades-old switchgear and relays to synchronize with the new system.

Kirschenbaum said DRUPS was “by far the most economical solution” for the university’s needs. “It provided the operational reliability we had been seeking,” he noted. “As an all-around project, it provided everything we were hoping for but realistically didn’t expect.”

Kirschenbaum said the DRUPS system has been activated successfully multiple times since its commissioning. The new system proved its dependability just weeks after commissioning, when a rare Seattle ice storm caused a huge power sag. The DRUPS immediately bridged the gap and UW’s heating plant stayed up.

Another notable event was a windstorm that caused the plant to experience more than 40 separate voltage sags, but never a loss of power. The DRUPS activated four times during that period. As an example of its operation, when the DRUPS activates, it monitors incoming power quality for 20 minutes. If it sees any issues, it then resets the clock. During one of the activations, the DRUPS continued running for more than an hour, so it covered multiple voltage sags.

Kirschenbaum said it’s not confirmed that one of those sags would have tripped the plant, but he is sure that individual pieces of equipment would have been lost multiple times without the DRUPS. As Kirschenbaum noted, the DRUPS prevented the operators’ boring day from turning into a very busy one.

—Darrell Proctor is a senior editor for POWER.