Water-Capturing Cooling Tower Technology Makes Headway at MIT

A cooling tower water recovery system designed by engineers from the Massachusetts Institute of Technology (MIT) could capture water from power plant fogs and plumes, potentially rendering them into a source of clean drinking water.

The system, which in May won MIT’s $100,000 Entrepreneurship Competition and forms the basis of startup company Infinite Cooling, uses electrical forces to overcome aerodynamic drag forces, explained Maher Damak, PhD 2018, and associate professor of mechanical engineering Kripa Varanasi, in a research article published in June in the journal Science Advances.

The principle behind the concept is relatively simple: zapping air-rich in-fog with a beam of ions electrically charges water droplets; these droplets can then be drawn toward a mesh of wires, captured, and drained into a collection pan. That “harvested” water can then be reused by the power plant or sent to a city’s water supply system.

Fog-harvesting is hardly new. In areas prone to dense fog, which are usually close to oceans, fog-collectors are sometimes used to capture fog, which is composed of tiny droplets with a typical diameter of 10 micrometers. Common designs for fog collectors include a mesh that stands perpendicular to the fog-laden wind. However, according to Damak and Varanasi, who are among Infinite Cooling’s co-founders, these meshes typically have low efficiencies—only about 1% to 2%. A key mechanism that limits the efficiency of mesh-based fog collectors is the “aerodynamic deviation” of fog droplets. As a stream of air passes an obstacle—such as the wires in mesh fog-catching screens—the airflow naturally deviates around the obstacle. The deviating airstreams send droplets off to the side rather than toward the wire’s center. That typically means that the fraction of captured droplets compared to those initially directed toward the individual wires in the mesh is much lower.

The researchers’ water recovery system is designed to overcome the fundamental aerodynamic limitation of streamline deviation by introducing an electrical force to overcome the aerodynamic drag force and propel the fog droplets toward the collector. The approach, Damak and Varanasi said, was inspired by the principles of electrostatic precipitators. When incoming fog is zapped with an ion beam, droplets on the path of the wires as well as those aiming for the holes get pulled toward the wires. “The equipment is simple, and the amount of power required is minimal,” they said.

To put the concept to practical use, Damak, Varanasi, and another graduate student Karim Khalil, focused on capturing water from power plant cooling tower plumes, which they noted is much more concentrated than any naturally occurring fog. “It’s distilled water, which is of higher quality, that’s now just wasted,” Varanasi said. “That’s what we’re trying to capture.” The water could be piped to a city’s drinking water system, or used in processes that require pure water, such as in a power plant’s boilers, as opposed to being used in its cooling system where water quality isn’t as critical.

According to Varanasi, a 600-MW power plant could capture 150 million gallons of water a year—which represents about 20% to 30% of water lost from cooling towers. Further refinements could make the system even more efficient, he said. The water recovery system could also serve as a simple desalination service. Installing the conversion system would cost about a third of that to build a new desalination plant—and its operating costs would be about 2% compared to a desalination plant. It would also have virtually no footprint.

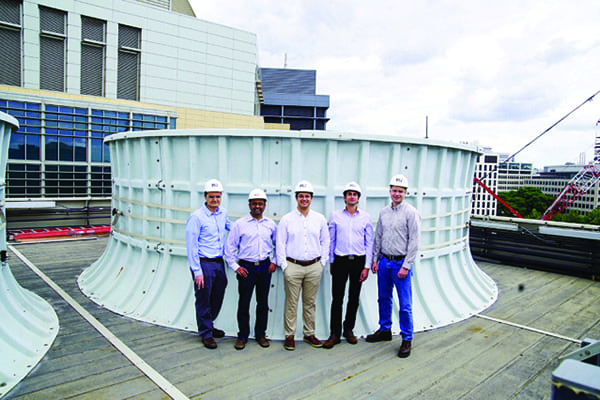

The researchers have already demonstrated the concept in a small lab version of a stack. They are now building a full-scale test version, which will be placed on the cooling tower of MIT’s Central Utility Plant (Figure 4), which is a natural gas–fired cogeneration plant that provides most of the heat and power on campus. Testing, which is expected to begin this fall, will include trying different variations of the mesh and its supporting structure, Damak said.

—Sonal Patel is a POWER associate editor.