In a brief interview this February, Francesco Venneri, Ultra Safe Nuclear Corp. CEO, explained to POWER why the company’s development of its proprietary fully ceramic microencapsulated (FCM) fuel is significant for the future of advanced nuclear, and how the company plans to roll it out.

Seattle-based Ultra Safe Nuclear Corp. (USNC), developer of the 5-MWe (15 MWth) Micro Modular Reactor (MMR) design, has garnered much attention for its progress in Canada—a nation that in December rolled out a small modular reactor (SMR) action plan to establish its leadership in the burgeoning global SMR landscape. Lesser discussed, however, are USNC’s contributions to a glaring gap in Canada and around the world to establish suitable nuclear fuels for SMRs.

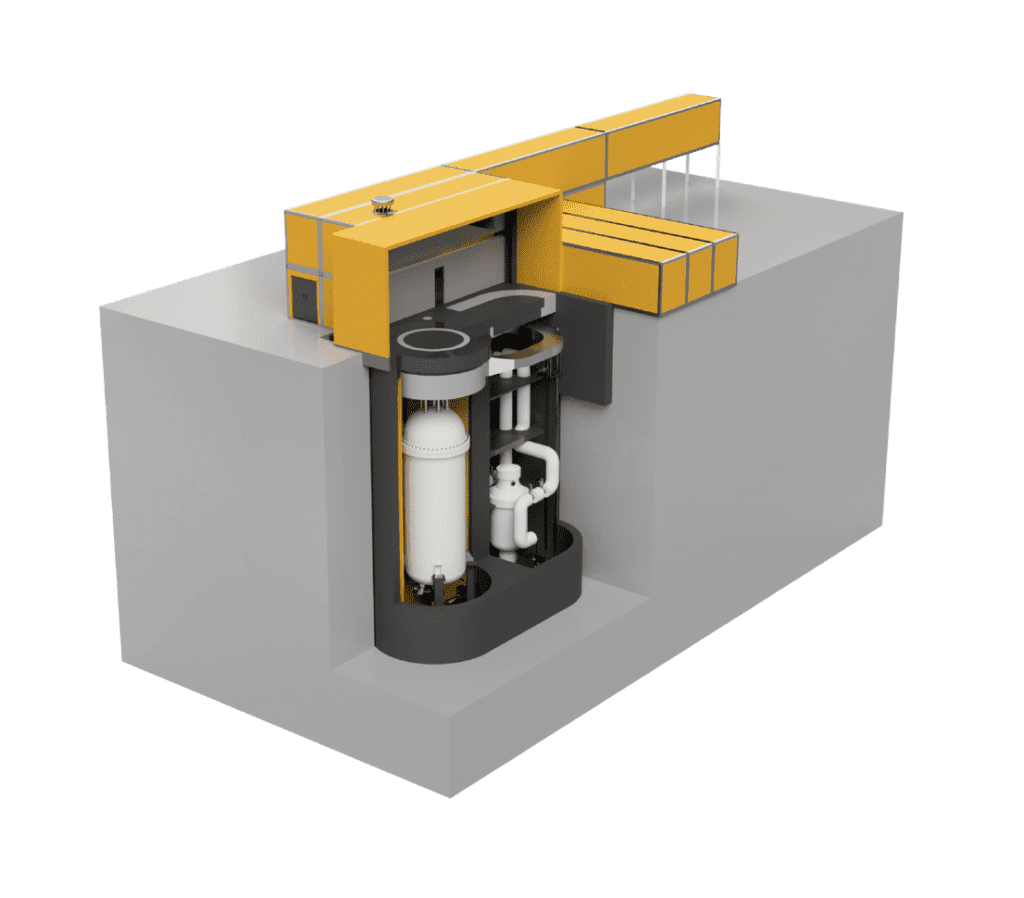

USNC’s MMR, high-temperature gas-cooled reactor (HTGR) microreactor, is poised to become Canada’s first SMR under a proposed project spearheaded by Global First Power, a joint venture partnership between Ontario Power Generation (OPG) and USNC Power, to build a full-scale reactor at Chalk River Laboratories, a sprawling 10,000-acre site in Ontario operated by Canada’s nuclear science and technology agency Canadian Nuclear Laboratories (CNL). While CNL wants to begin operating an SMR by 2026, and the MMR project could serve as a pivotal demonstration to show how nuclear microreactors could support heavy industry and other off-grids uses, the project’s timing is heavily dependent on completion of the environmental assessment and licensing activities.

The significance of Canada’s SMR action plan is that “it demonstrates the need for SMRs, these very distributable, scalable clean heat and electricity sources in numerous parts of our economy and in important parts of our society,” as John Gorman, president and CEO of the Canadian Nuclear Association (CNA) recently told POWER. SMRs “are going to be deployed much sooner than most people think in the Canadian context,” he said.

Canada’s Advanced Nuclear Fuel Gap

Efforts were recently buoyed by OPG’s November 2020 announcement that it will resume planning activities for an SMR of between 1 MW and 300 MW on its Darlington site, with deployment slated for as early as 2028. In October, the utility announced it would advance engineering and design work with GE Hitachi Nuclear Energy (GEH), Terrestrial Energy, and X-energy. Four utilities, covering four different provinces, have also laid out a business plan to explore SMR use for different applications,” Gorman noted. These “streams” involve larger grid-connected SMRs such as in Ontario and Saskatchewan; Gen IV SMRs, investments in which are underway in New Brunswick; and microreactors for the mining and extraction industries that could deliver heat to produce high temperature stream.

The federal government’s Dec. 18-issued SMR action plan lays out 50 recommendations in areas such as waste management, regulatory readiness, and international engagement, as well as to develop coordinated procurement through cohesive supply chains. If there is a gap, Gorman said, it concerns procurement of enriched uranium nuclear fuel. All of Canada’s 19 operable reactors—which provide 13.5 GWe of power capacity—are Canada Deuterium Uranium (CANDU) pressurized heavy water reactors (PHWRs), which means they use natural uranium (fuel in the form of uranium oxide powder packed into pellets and placed into fuel rods) as their nuclear fuel. Nearly all SMRs under consideration in Canada will use fuel types that are different from the natural uranium bundles the nation currently uses.

“Our regulatory system is kind of silent on whether or not we can actually make enriched uranium here,” Gorman said. “Most of our major producers of uranium—the ones that handle it and turn it into fuels—they’ve got major presence on both sides of the border. I guess to a certain extent, the big players like Cameco and BWX Technologies will have to decide what kind of approach they want to use,” he added. “A perfectly viable avenue is to get into an arrangement with the U.S. to get our enriched uranium from the U.S. That’s a perfect example of why we need these talks around reciprocating and transparent borders.”

Progress for Advanced Nuclear Fuel in the U.S.

As POWER has reported, to support its own ambitions to deploy a commercial SMR fleet within the next decade, the U.S. is aggressively acting to address the “technology gap” that exists for high-assay low-enriched uranium (HALEU) fuel systems, materials, and fabrication technologies for compact, power-producing, and high burnup applications, such as would work for (presumably military) off-grid power sources and transportable systems.

Outside of public research limitations, private technology developers are making headway, especially to develop tristructural-isotropic (TRISO) fuel. While it still has no commercial power-producing users, TRISO—a type of HALEU fuel—is seeing a resurgence of interest in the U.S., where it was first developed in the 1960s for gas-cooled reactors.

On March 1, notably, X-energy, a winner of the Department of Energy’s (DOE’s) Advanced Reactor Demonstration (ARDP) program, announced it signed a cooperative agreement with the agency, officially marking the beginning of the company’s participation in the program. In October, the DOE awarded the Rockville, Maryland–based firm $80 million in federal funding to build a commercial four-unit power plant based on its Xe-100 reactor design, an 80-MWe/200-MWth pebble-bed HTGR, which can be scaled as a four-pack to 320 MWe.

The funding will also support X-energy’s delivery of a commercial-scale fuel fabrication facility for its proprietary TRISO-X fuel, which it developed under the 2015 DOE Advanced Gas Reactor (AGR) Fuel Qualification Program. “This ~$2.5 billion project will enable X-energy to build the world’s first commercial scale advanced nuclear reactor with Energy Northwest in Washington state,” the company said on Monday. In total, the DOE will invest approximately $1.23 billion in X-energy’s project over the seven-year period for this demonstration, it said.

The Significance of FCM Fuel

USNC, a notable private TRISO fuel developer, is spearheading development of its proprietary Fully Ceramic Microencapsulated (FCM) fuel. This September, the company established a new facility in Salt Lake City, Utah, to support the development of its FCM fuel and materials that will be used in its own MMR, as well as other nuclear reactors, including gas-cooled reactors, light water reactors, CANDU reactors, and molten salt cooled reactors.

Venneri, USNC’s CEO, told POWER the company has marked several milestones since it initiated development of the MMR and FCM fuel in 2011. This interview has been edited for clarity.

POWER: What is FCM fuel, and why is it considered innovative?

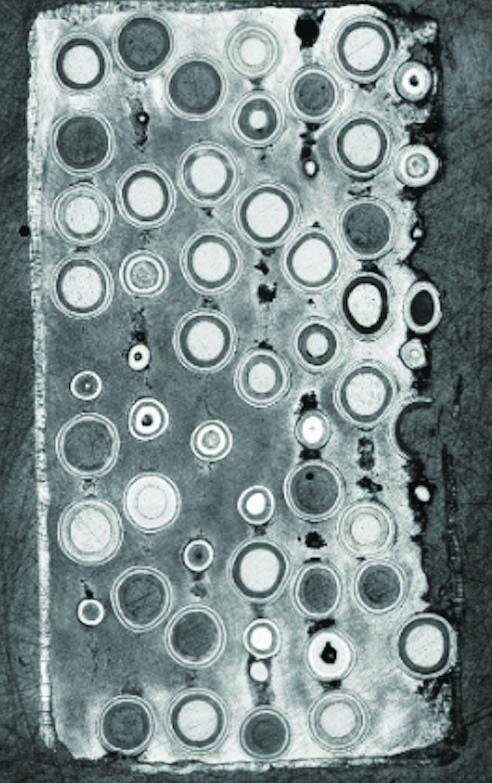

Venneri: Fully ceramic microencapsulated (FCM) fuel consists of coated nuclear fuel particles embedded inside a dense and fully sealed silicon carbide (SiC) matrix. The specific coated fuel particles are TRISO microspheres that provide micro-encapsulation of the fuel with multiple pyrocarbon and a SiC coating layer. Using FCM technology, an additional layer of protection against radionuclide release is added by taking advantage of SiC as the matrix for these coated fuel particles. This macro-encapsulation further enhances radionuclide retention capability of the fuel and allows for design and deployment of ultra-safe nuclear energy systems.

Historically the TRISO fuel particles are compacted inside a graphitic matrix that is susceptible to corrosion and oxidation, degrades with irradiation, and does not provide a strong barrier to any potential radionuclide release. The FCM technology provides this new strong additional barrier while also enhancing the environmental stability, heat dissipation, repository performance, and proliferation resistance of the fuel during operation and after its discharge.

POWER: Are there specific geometries or materials that USNC’s fuel uses that others don’t?

Venneri: USNC utilizes the proven TRISO fuel architecture and combines it with SiC matrix to produce a high-performance fuel form. FCM may host the well-established uranium oxide-carbide (UCO) TRISO particles or more recently developed variants such as the uranium nitride (UN) TRISO. The SiC matrix may be produced using conventional methodologies that allow for relatively simple geometries such as cylindrical compacts or via additive manufacturing methods that facilitate production of fuel elements with highly complex configurations. The advanced TRISO and manufacturing technologies have been systematically tested at Oak Ridge National Laboratory (ORNL) and through leveraging and licensing of these technologies, Ultra Safe Nuclear is able to develop tailored energy systems and facilitate their industrial deployment.

POWER: How was FCM tested, and what does the testing show?

Venneri: The constituents of FCM fuel form, the fuel particles and the SiC matrix, have undergone separate effects irradiation testing inside a U.S. DOE research reactor (at the High Flux Isotope Reactor at Oak Ridge National Laboratory). Integral FCM fuel elements are also being irradiated inside this reactor. As expected, the experimental data to date show that FCM is a highly radiation stable and robust fuel form. To expand on these activities and support the licensing basis for this fuel form, Ultra Safe Nuclear is orchestrating its own irradiation campaign at other test reactors to supply data specific to MMR operating parameters.

POWER: What progress has USNC made in the licensing process?

Venneri: The licensing process for the FCM fuel form is integrated with the overall radionuclide retention strategy and licensing basis for USNC’s MMR power systems. Ultra Safe Nuclear is taking advantage of modern licensing strategies that involve a combination of high-quality test data from experimental irradiation campaigns coupled with advanced modeling and simulation. In this manner, proven methodologies and supporting data with nuclear quality rigor requirements are provided to the regulators to facilitate licensing. Ultra Safe Nuclear targets integration of fuel and reactor licensing strategies to ensure and secure an efficient and swift licensing process.

POWER: USNC recently established a facility in Salt Lake City. What does this mean for the future of advanced nuclear?

Venneri: Establishment of the Salt Lake City facility is key for scale up of advanced ceramics production technologies that enable Ultra Safe Nuclear‘s advanced MMR systems. Ultra Safe Nuclear is also pursuing another site to expand these capabilities and is currently considering the states of Washington, Tennessee, and Utah for this new facility. Proximity and close partnership with U.S. DOE national laboratories and sites will be key to any advanced reactor demonstration in the U.S.. Ultra Safe Nuclear has formed strong partnerships with many of these laboratories and is able to leverage significant expertise and capabilities within these organizations to deliver its advanced nuclear energy systems.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).