Stepping up efforts to develop a hydrogen gas turbine, Doosan Heavy Industries & Construction (DHIC) and a consortium of partners will begin South Korea’s first large-scale hydrogen gas turbine demonstration at the 1.8-GW Ulsan Combined Cycle Power Plant by 2027.

DHIC, a regional energy technology conglomerate, on June 3 said it signed a series of agreements with the city of Ulsan in southeastern South Korea, Korea East-West Power (EWP), and leading domestic liquefied petroleum gas provider SK Gas to pursue a hydrogen gas turbine demonstration project. The demonstration at the Ulsan combined cycle plant, a 2014 POWER Top Plant facility that is today fired with liquefied natural gas (LNG), will essentially convert a 25-year-old gas turbine into a 270-MW hydrogen gas turbine.

Under the agreements, the city of Ulsan—which is nicknamed “Hyundai City”—will provide administrative support on implementing the infrastructure needed for the “hydrogen gas turbine business,” whereas EWP, a 2001 spinoff of Korean Electric Power Corp. (KEPCO), will handle the demonstration of the hydrogen gas turbine using South Korean technology. SK Gas will spearhead laying the foundation for hydrogen supply, while DHIC will oversee technology development and supply the hydrogen gas turbines. “We plan to use these agreements as a stepping stone to develop the hydrogen gas turbine business into the next-generation growth engine,” said Yeonin Jung, DHIC chief operating officer. “It is all the more significant as we will be able to supply the local communities with eco-friendly energy.”

DHIC Spearheading Domestic Gas Turbine Development

The development is a notable acceleration of DHIC’s efforts to establish itself at the core of South Korea’s strategy to become only the fifth country to own an independent gas turbine model. The company last year cemented dual contracts valued at a total $300 million with Korea Western Power Co. (KOWEPO) for the construction of the 500-MW Gimpo Combined Heat and Power (CHP) plant using a gas turbine technology it developed as part of a South Korean–government led initiative.

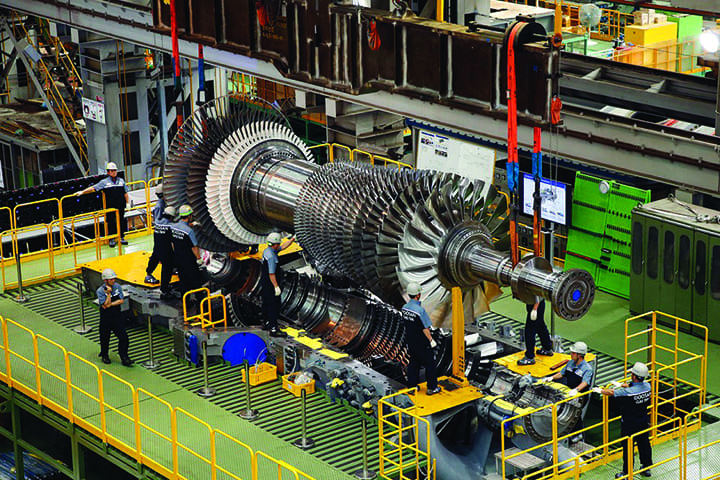

DHIC has invested $830 million in research and development as part of the government-led effort for the project’s flagship 270-MW class large gas turbine model, the DGT6-300H S1. Developed with advanced technologies—including ultra-heat-resistant alloys and precision casting, the 270-MW model has more than 40,000 parts, including 450 blades. It features “axial compressor technology that compresses a large volume of air to up to 24:1; a combustor technology that minimizes exhaust gas; and a system integration technology for assembling the core components of the compressor, combustor, and turbine.” These efforts have enabled a combined-cycle efficiency “of more than 60%,” the company said last year.

In September, DHIC also signed an MOU with KEPCO, five power sector companies—including Korea South-East Power Co., Korea Midland Power Co. (KOMIPO), KOWEPO., Korea Southern Power Co., and EWP—to implement an LNG combined cycle power plant.

Meanwhile, DHIC says that it is developing its own 100% hydrogen-fueled 5-MW gas turbine combustor. However, since May 2020, it has also partnered with the Korea Institute of Machinery and Materials (KIMM) to develop a dual-fuel combustor for a 300-MW hydrogen gas turbine that can burn hydrogen in fuel mixes of at least 50%. Under an MOU DHIC signed with KOMIPO on June 2, notably, KOMIPO agreed to adopt Doosan’s technology for this hydrogen dual-fuel combustor and its hydrogen gas turbine.

DHIC says, citing KIMM, that hydrogen-fueled power plants may emit fewer pollutants compared to conventional LNG-based combined cycle power plants. “If a 30% hydrogen fuel mix is used, a CO2 emissions level that is 10.4% less than LNG-based power plants can be achieved and if a 50% hydrogen fuel mix is used, the emissions level can be [reduced] by up to 21.4%,” it said. “Power plants that are fueled 100% by hydrogen generate zero carbon emissions.”

Doosan Expanding its Hydrogen Potential

These efforts are also rooted in DHIC’s strategy to diversify its hydrogen business portfolio. In tandem with its hydrogen gas turbine development, it is currently planning to acquire a technology “track record” for producing blue and green hydrogen and “build up” its hydrogen-related equipment business.

So far, it is looking at building a hydrogen liquefaction plant within its Changwon complex in Jeju, where its global headquarters are sited, by 2022. At the liquefaction facility, Doosan will employ “high efficiency” carbon capture, utilization, and storage technology to produce blue hydrogen. Meanwhile, it is also developing a project to produce green hydrogen using wind power on Jeju island.

“The option of applying small modular reactors (SMRs) to produce clean hydrogen is also being reviewed. Given that renewable energy, such as solar and wind energy, and nuclear power, are all sources that emit zero carbon emissions, they are receiving attention both at home and abroad as viable energy sources for achieving clean hydrogen production,” the company told POWER.

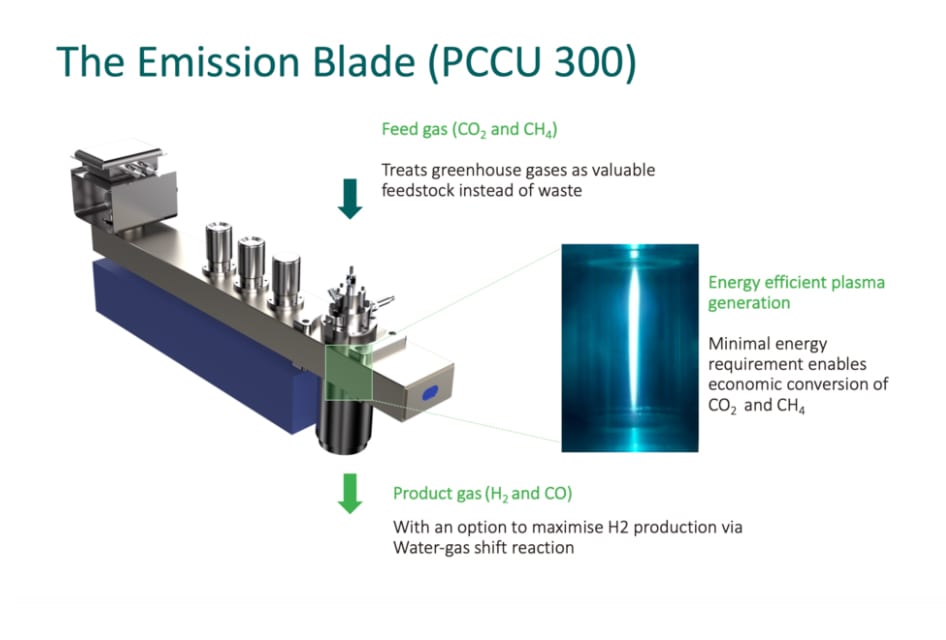

Finally, DHIC subsidiary Doosan Mecate has acquired shares in ReCarbon, a company that in 2018 commissioned a module of its 72 x 1 kW “emission blade” plasma carbon conversion unit (CCU) at the Daegu municipal landfill, utilizing CO2 from the landfill gas generated by organic solid waste, and methane.

ReCarbon’s microwave plasma technology essentially works to convert greenhouse gases into syngas; it then separates the hydrogen component through a pressure swing adsorption system that is capable of achieving a 99.99% hydrogen purity. That hydrogen is then “filled” in a stationary hydrogen fuel cell power plant through a hydrogen purification unit.

ReCarbon says its plasma-based CCU technology was in July 2020 commissioned at the Bradley County, Tennessee, landfill site through a partnership with H2Renewables, a Santek Waste Services company. The project is operating as designed, Philip Sohn, executive vice president of Business Development at ReCarbon, told POWER on June 10. H2Renewables and ReCarbon are now expanding that site with a project slated for construction in 2022 that has a capacity to produce 12 tonnes of hydrogen per day from landfill gas.

“The current plant was built to test the landfill gas scrubbing projects. We are also announcing a broader agreement soon,” Sohn said. “Aside from the biogenic hydrogen space, which we are developing in many countries presently, we also have a significant business converting industrial CO2 into syngas-based products, such as methanol, ethanol, chemicals, and plastics.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).