Currently, Poland is trying to reconcile its recent hard-won freedom and cultural openness with its centuries-long history of oppression at the hands of a number of conquest-driven marauders. From the time of the Crusades through the Teutonic Knights, Tartars, Cossacks, and Turks; through three partitions; and through the most recent occupations during two world wars, Polish citizens have dealt with many challenging times, particularly during the 20th century.

Starting in 1981, the beginnings of the "Solidarity" trade union contributed to the fall of communism. Finally, in 1989, free, democratic elections marked the end of the communist regime imposed on Poland by the Soviet Union.

A "shock therapy" program during the early 1990s enabled the country to transform its economy into one of the most robust in Central Europe, according to the U.S. Central Intelligence Agency’s World Factbook. However, despite recent changes resulting from EU development programs, Poland still faces the lingering challenges of high unemployment, underdeveloped infrastructure, and a poor rural underclass.

Poland joined NATO in 1999 and the European Union in 2004. With its transformation to a democratic, market-oriented country largely completed, Poland is an increasingly active member of Euro-Atlantic organizations.

The Polish Power Industry

Given Poland’s history as a communist country from the 1940s through the late 1980s, it’s not surprising that the Polish government managed power generation assets and the distribution of electricity for many years.

In an interview with POWER in January, Gene Larson, vice-president of business development with SNC-Lavalin Constructors Inc., described how the electric utility industry in Poland has evolved in recent years. He served as the director in his company’s Warsaw, Poland, office during the effort to restart construction of the Patnów II Power Plant in north-central Poland.

"In preparation for accession into the [European Union] EU, Poland was required to liberalize its electricity sector, including creating policies for opening the power markets and privatizing the large state-owned electrical generation companies," Larson said. "Most of the existing generation assets were completed prior to 1970 and are based mostly on Soviet-designed power plants, both inefficient and highly polluting, supplemented by British-designed mid-sized steam turbine technology."

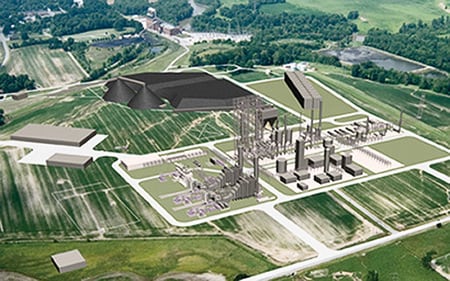

Larson pointed out that the Patnów II plant was the first of a series of planned projects to demonstrate leading-edge technology for coal-fired power plants, which still generate over 94% of the power in Poland. Patnów II is the largest new project recently completed and is both highly efficient and less polluting than any other project currently operating in the Polish market: It meets emissions requirements of both the EU and the Kyoto Protocol (Figure 1).

1. Polish pride. The Patnów II Power Plant represents a new era in electricity generation for Poland. The plant will sell a portion of its power to the Polish grid company, PSE. Courtesy: SNC-Lavalin Constructors Inc.

According to Larson, other new high-efficiency and clean-burning plants are currently under design or construction by Poludniowy Koncern Energetyczny (PKE) at Lagisza (a 460-MW circulating fluidized bed plant) and PGE Elektrownia Belchatow (an 858-MW circulating fluidized bed design). Neither would have been easily funded had SNC-Lavalin not found a way to reenergize the lenders involved with the Patnów II project.

"Following a turbulent path towards deregulation and privatization during the 1990s and early 21st century, today there are four integrated Polish utilities: ENEA S.A., Polska Grupa Energetyczna S.A. (PGE & PSE), Tauron Energia S.A., and Energa S.A.," Larson said.

At present, a number of Polish government entities are involved with the electric power industry. The main government agency in Poland that deals with the electric generation industry is the Ministry of Economy, and the Urzad Regulacji Energetyki (the Energy Regulatory Office) regulates the power sector. The country’s national grid company is Polskie Sieci Elektroenergetyczne (PSE) Operator S.A.

Plant Profile

According to Andrzej Mich, manager of engineering for SNC-Lavalin Polska, the new 460-MW Patnów II unit was designed to replace two old 200-MW oil-fired power units.

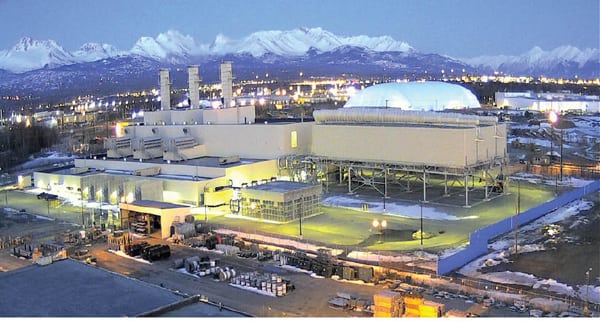

"The new unit is a supercritical design with parameters of live steam [at] 540C and 25.0 MPa and hot reheat steam [at] 565C and 5.2 MPa," he said. "Gross electrical output at design conditions is 469 MW with a gross efficiency of 44% exported to the Polish grid at 400 kV. The unit is equipped with the following auxiliary systems: once-through cooling, coal handling, fly and bottom ash handling, start-up fuel oil, water treatment plant, and a wet flue gas desulfurization" (Figure 2).

2. Lakefront property. Intake water is drawn from the lowest of three cooling lakes (top) and discharged into a weir, where the water flows to the highest cooling lake, from which it cascades back down to the intake. Only the lowest lake is used in the winter due to ice build-up on the upper lakes. Courtesy: SNC-Lavalin Constructors Inc.

Patnów II fulfills EU regulations related to air emissions, Mich stated. Due to its new air pollution control technology, the plant’s emissions numbers are as follows:

-

NOx as nitrogen dioxide (NO2) below 200 milligrams per normal cubic meter (mg/Nm3).

-

Sulfur dioxide (SO2) below 200 mg/Nm3.

-

Ash content below 30 mg/Nm3.

The Project’s Past Financial Challenges

SNC-Lavalin Constructors’ involvement in the construction of Patnów II has an interesting history.

In 2003 the company decided to evaluate the market in Europe, Larson explained. "In March of 2003, Ron Denom, now president of SNC-Lavalin International, brought to our attention Patnów II, a suspended lignite-fired project in Poland," he said. "Further investigation revealed a somewhat ‘Enron-esque’ nature to the project. It was started by Elektrim, the holding company controlled by Polish media mogul Zygmunt Solorz-Zak, which also has a 46% stake in power company ZespóÅ‚ Elektrowni Patnów-Adamów-Konin SA (ZE-PAK), whose other key owner is Poland’s treasury."

Elektrim Megadex, the engineering, procurement, and construction (EPC) contractor that began design and construction of the Patnów II project, was a wholly owned subsidiary of Elektrim, Larson explained. Elektrim had significant assets in the telecommunications industry, and when these assets were devalued by a worldwide telecom market collapse in 2001 and 2002, the bank club that was originally assembled to finance the Patnów II project declined to fund it. Elektrim continued to bankroll the project, investing nearly a billion Polish zloty (approximately 206 million euros at the time) before finally suspending project activities in 2003.

The basic plant design included the most modern technology. It utilized a supercritical pulverized coal boiler, which was designed by Alstom and manufactured and erected by the consortium Alstom-Rafako. The design also included a 460-MW steam turbine designed and supplied by Alstom Power. The boiler structure was completed and some of the pressure elements were already hung in the boiler building when design and construction ceased. Overall progress was between 25% and 30% when construction stopped in 2002.

"SNC-Lavalin saw the opportunity to lend their strong balance sheet and extensive EPC construction experience to the formula needed to reassemble the bank club and have them begin funding the project." Larson said. "SNC-Lavalin carried out cursory due diligence work on the status of the project, and a short competition by two companies, including SNC-Lavalin, began. After preliminary terms were discussed, SNC-Lavalin was selected as the potential EPC contractor, and negotiations with Elektrim and the lenders took over a year to complete. Discussions on restarting the project with all the key suppliers and vendors added another six to eight months to the process. A contract was finally signed in July 2004 with design and construction restarting shortly thereafter. The plant reached full power in December 2007 and was taken over by the client on June 31, 2008."

During the three-and-a-half-year period needed to finish the Patnów II project, world power markets experienced unprecedented escalations in the price of commodities and engineered products. The now-completed Patnów II project, even with the additional costs of bringing the project out of suspension, is a relative bargain by today’s standards: Final costs total approximately $460 million euros, or an EPC price of $996 euros per kW (US$1,300 per kW).

Overcoming Construction Difficulties

"The challenges inherent in this project were many and varied," Robert Cano, senior project director with SNC-Lavalin, told POWER in January. "Work on the project had been suspended in 2002 due to collapse of the planned financing. At that time the work had progressed to approximately 30% completion. Thirty subcontracts had been awarded by the original EPC contractor, and these contracts were taken over by SNC-Lavalin in 2005 when the project was restarted."

The difficulties in remobilizing and effectively restarting construction during Poland’s coldest winter in the previous 30 years were compounded by the country’s entrance into the EU and a massive exodus of labor to Western Europe, according to Cano. At the same time, Poland was experiencing a construction boom that further strained the ability of contractors to take on large projects. This resulted in a significant restructuring of the original subcontract execution plan to provide for smaller work packages that widened the pool of available contractors.

Restarting the design effort presented challenges for many of the same reasons that affected the construction effort, Cano explained. Engineering for the systems outside the scope of the major original equipment manufacturers was performed by three large Polish firms that had been contracted by the original EPC contractor. Additionally, resuming a design that had been initially developed during the pre-EU period required a significant period of analysis and review to confirm compliance with EU directives that subsequently had been adopted by Poland.

Cano noted that the greatest technical challenge revolved around processing and delivery of the fuel. The fuel used at Patnów II is a poor-quality brown coal, or lignite. The lignite contains a large quantity of fibrous, woody material referred to as xylites, which cannot be crushed with conventional equipment. Instead, they must be separated, chopped, and then returned to the fuel mixture (Figure 3).

3. Coal-handling operations. This side view of the boiler building and steam turbine building shows the structural framework for supporting the feed conveyor to the coal hoppers. Courtesy: SNC-Lavalin Constructors Inc.

Larson also shared his observations about some of the problems the construction team initially faced.

"Another interesting aspect of bringing a project out of suspension and restarting [it] is determining the current status and the ability to update the exiting 3-D model of the project," he said. "A total of seven different companies played a significant role in the detailed design of the project and integration of the input from all these entities was a significant challenge to the project. Having inherited the structure from Elektrim Megadex, SNC-Lavalin chose to continue with the key parties involved in the detailed design — overseeing and managing the process to ensure smooth integration into the overall design concept."

Similarly, with multiple subcontractors performing construction activities on the site simultaneously, the 3-D model that was created was invaluable in resolving workspace allocation issues and routing critical mechanical and electrical systems throughout the boiler and steam turbine buildings without major interferences, Larson noted.

The Impact of Environmental Concerns

Another hurdle the SNC-Lavalin team faced in resurrecting Patnów II was dealing with major Polish and EU environmental laws and regulations that affected plant design and operations.

"One of the several unique aspects of the Patnów II plant was the fact that it was approved, designed, and essentially manufactured under one set of environmental standards (Polish standards), and then, in order to be completed, had to conform to the new EU standards that came into effect as we were negotiating to bring the project out of suspension," Larson said. "Both the EU pressure equipment directives and the new EU emissions standards were exhaustively vetted by the regulatory entities prior to allowing the project to continue."

In addition, Larson discussed the environmental issues associated with using lignite as a fuel source. As mentioned earlier, a large number of xylites (long, stringy, fibrous strands that are unique to Polish lignite) are found in the coal used by this plant. Xylites make the lignite difficult to crush, pulverize, and combust.

"Lignite is a common fuel in use worldwide," Larson said. "According to a technical paper on lignite published by the U.S. Environmental Protection Agency (EPA), ‘the major advantages of firing lignite are that it is relatively abundant, relatively low in cost since it is surface mined, and low in sulfur content, which can reduce the need for post-combustion sulfur emission control devices.’"

Lignite’s disadvantages are that more fuel and larger, more capital-intensive facilities are necessary to generate a unit of power than with bituminous coal, according to the EPA. These disadvantages arise because:

-

Lignite’s lower heating value means that more fuel must be handled to produce a given amount of power.

-

The energy and maintenance costs of coal-handling equipment are higher.

-

The high inherent moisture content of lignite decreases boiler efficiency.

-

Lignite’s ash characteristics require more attention to sootblowing and boiler operation to maintain high availability and reliability.

A Brighter Future

The suspension of the Patnów II project effectively froze development of new power projects in Poland for several years, according to Krzysztof Michalczuk, vice-president, business development for SNC-Lavalin Polska. Even with the substantial equity invested by Elektrim, the bank club formed for the project would not finance it. Bringing the project out of suspension and to successful completion has opened the door to lenders financing other projects in Poland and has allowed significant modernization to occur. Michalczuk indicated that, having established an experienced team of managers and engineers based in Poland, his company is now well-positioned to support the future growth of power opportunities throughout Eastern Europe.

Although the bulk of the power generated by Patnów II is likely to be used in Poland, some may cross the border into Germany. The impact of the new efficiency and clean emissions of this project will help establish a benchmark for future projects in Poland and show how to generate more electricity in an environmentally sustainable manner.

–Angela Neville, JD is POWER’s senior editor.