This May, following two years of construction, Siemens Energy put into operation Irsching 5, an 847-MW advanced combined-cycle power plant near Ingolstadt, Germany. The plant’s owner, Gemeinschaftskraftwerke Irsching GmbH—a joint venture of E.ON, Mainova, and HEAG Südhessische Energie—features two SGT5-4000F gas turbines, one SST5-5000 steam turbine, three hydrogen-cooled generators, electrical systems, and Siemens’ SPPA-T3000 instrumentation and control system.

The plant is designed for 250 starts annually and reaches full output in just 30 minutes to meet grid requirements for the integration of wind power, Siemens said. The plant’s F-class gas turbine technology and quadruple-flow low-pressure steam turbine pushes its efficiency to more than 59.5%. But this isn’t the best in Siemens’ arsenal of gas turbines anymore. According to the German company, that title is reserved for its new 60-Hertz SGT6-8000H gas turbine. Florida Power & Light will be that model’s first customer.

At a press conference this June to mark commercial availability of the H-class turbine after a nearly decade-long development phase that took it from prototype to marketing, the company said it had achieved “a masterpiece of engineering” that sets a world-record efficiency of 60%. It also claims that, compared to solutions installed at combined-cycle power plants, the new generation of gas turbines consumes one-third less natural gas and emits one-third less carbon dioxide. Added to that, while temperatures inside the combustion chamber reach up to 1,500C, the turbines can go from standby to start-up in 5 minutes and reach full power operation in just 15 minutes. “They need only minutes to switch from full power to half power or vice versa, enabling them to optimally compensate for natural fluctuations in rapidly increasing grid feed-ins from wind and solar energy sources,” the company said.

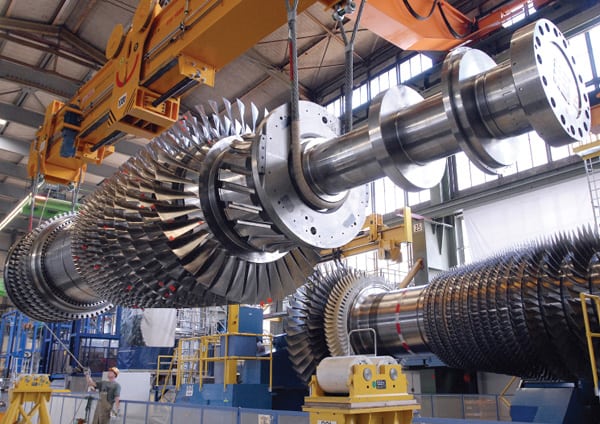

A brainchild of Siemens and Westinghouse engineers, the H-class consists of more than 7,000 individual parts (Figure 1). The largest model available weighs a stunning 444 metric tons—as much as a fully fueled Airbus A380—and, according to Siemens, the distance between the blades and the housing is as small as the thickness of a postcard. The company adds: “Turning at more than 1,700 kilometers an hour, some parts of the turbine blades exceed the speed of sound when in operation.”

|

| 1. In a class of its own. Siemens Energy marked commercial availability of its SGT6-8000H gas turbine, shown here, this June. The so-called H-class gas turbine is the result of a nearly decade-long development phase and is the highest efficiency class currently available, Siemens says. The SGT5-8000H was tested more than 1,500 hours at a simple-cycle power plant at Irsching 4 in Bavaria, Germany. Courtesy: Siemens Energy |

The H-class turbine is in the “two- to three-digit million [dollar] range,” yet it already has its first customer—and Siemens expects to sell at least 10 a year in the medium term. Florida Power & Light in June signed up for six 60-hertz, 274-MW H-class turbine generator packages for the modernization of its Riviera Beach and Cape Canaveral Next Generation Clean Energy Centers in Florida. The utility said its decision was based on “long-term strategic decisions” that would comply with stricter anticipated environmental controls in energy legislation.

The shift to gas-powered generation is gaining speed across the pond, too, fueled by a recent plunge in natural gas prices, new shale gas mining, and campaigns against new coal power plants. In the UK—a country that produced 47% of its power with natural gas (compared to 34% from coal in 2008)—24 new gas-powered stations, nearly 29 GW, are under construction or in the planning process, compared with two planning applications for new coal plants.

|

| 2. Dash for gas. Gas-powered generation is gaining ground against coal in the UK, too, fueled by a recent plunge in natural gas prices, new shale gas mining, and campaigns against new coal plants. The growing market prompted Rolls Royce to launch the H63, the latest addition to a range of industrial gas turbines. This engine delivers 11 MW more power but in the same footprint as the RB211-GT61, and with an improved efficiency of up to 41.5%—the best in the 35 MW to 45 MW range, Rolls Royce claims. Courtesy: Rolls Royce |

Like Siemens, anticipating increased demand for high-efficiency gas turbines, UK company Rolls Royce in June rolled out the H63 (Figure 2), the newest model of its industrial RB211 gas turbine series. The 44-MW engine can deliver at least 30% more power than earlier models, Rolls Royce claims, with a thermal efficiency of up to 41.5% as well as operational flexibility. The technology builds on Trent aero technology and features high-pressure turbine rotor blades and intermediate compressor stators and rotors.