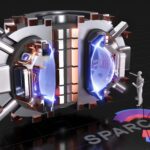

A key component of a system that would deliver fusion energy in the U.S. has arrived at Commonwealth Fusion Systems’ (CFS) campus in Devens, Massachusetts. The company on October 28 said the first half of the vacuum vessel at the heart of SPARC, the group’s tokamak machine, is now on-site.

The company on Tuesday said the “48-ton half-donut-shaped steel construction is instrumental to SPARC’s mission to demonstrate the core technology for our ARC fusion power plant,” adding, “We already have installed SPARC’s cryostat base in place, the foundation fusion machine called a tokamak, but the vacuum vessel gives a much better idea of SPARC’s final form and how it’ll carry us toward large-scale commercial fusion energy.”

Brandon Sorbom, the company’s chief science officer and co-founder, said, “This is a really exciting time because we’re starting to really see the pieces come together for SPARC.” The company is now set to begin a new phase of SPARC assembly, as CFS crews working on the floor of Tokamak Hall are preparing the vacuum vessel for use by first adding diagnostic equipment, and then components made of heat-tolerant tungsten metal.

Fusion-Friendly Environment

The vacuum vessel is the donut-shaped chamber inside SPARC. The vessel’s job is to house the superhot cloud of charged particles called a plasma, which is CFS’s fusion fuel. Officials said the vessel’s job isn’t to control the charged plasma — that’s done by magnets surrounding the vacuum vessel — but rather to “create an airless environment, like a pocket of outer space, in which the plasma can exist.”

Officials noted that “even a wisp of air in the vacuum vessel will snuff out the fusion reaction. The vacuum vessel is a super-tough component. It needs to withstand heavy heat loads from being near plasma that’ll exceed 100 million degrees Celsius. And it’ll need to shoulder the strong physical forces that SPARC’s magnets will exert.”

The company said that getting the vacuum vessel onto the CFS campus, and then inside Tokamak Hall for SPARC assembly, “required years of close coordination among several CFS teams—from diagnostics and design to thermal and structural engineering. But it also involved work to develop a supply chain that reaches outside CFS.”

Building the Fusion Supply Chain

“The vacuum vessel is really significant because it’s a big piece of work that’s been done in concert with one of our suppliers,” Sorbom said.

CFS has developed its own manufacturing abilities with key new technologies, such as the high-temperature superconducting, or HTS, magnets that are made in a magnet factory at the Devens campus. The company in a news release wrote, “Building a supply chain lets CFS complement that in-house capability by drawing on partners that already have the talent and know-how we need for other projects. Our vacuum vessel uses state-of-the-art technology, but manufacturing partners don’t need expertise in fusion science to build it to our specifications. That means our work in fusion energy can bring in new business to companies looking to expand—for example, the oil and gas industry’s suppliers that are already experts in fabricating sophisticated metal machinery. Today’s work on SPARC could lead to tomorrow’s work on many ARC power plants.”

Said Sorbom: “It’s a big moment for us because we have a big piece of hardware showing up, but it’s also just a really big moment for the industry. It’s a sign of how the supply chain is really maturing.”

—Darrell Proctor is a senior editor for POWER.