Most of today’s operating coal plants began service at least a generation ago and were designed to burn eastern bituminous coal. A switch to Powder River Basin coal can stress those plants’ boiler systems, especially the pulverizers, beyond their design limits and cause no end of operational and maintenance problems. Many of those problems are caused by failing to maintain good fuel fineness when increasing fuel throughput.

Many of our pulverized coal plants began life 30 or more years ago burning eastern bituminous coal. Utility practice at that 7. Predicting pulverizer performance. Four key parameters must be considered when assessing the performance of a pulverizer: fuel feedsize, fineness, moisture, and Hardgrove Grindabilty Index. Often pulverizers are called to perform far above their true capacity. Source: Storm Technologies Inc.time was to simply burn the coal particles until the flyash contained 3% carbon or less and then call it a day. That practice is antiquated by today’s competitive operating standards, yet the fuel preparation equipment we operate today remains unchanged.

Without question, the heart of a pulverized coal–fueled plant is its pulverizers. Familiar problems such as boiler tube slagging and fouling, excessive furnace gas temperatures, poor furnace combustion, and waterwall wastage are often traced back to poorly performing pulverizers. In my experience, about 75% of the efficiency improvements in coal-fired boiler systems center on the pulverizers and closely related issues of coal fineness, fuel distribution, fuel line balance, and primary airflow.

Last year (see POWER, October 2007, “Managing air to improve combustion efficiency”) I wrote about the importance of managing air throughout the steam generator system. This month, I direct your attention to properly managing the fuel component of the combustion equation.

Balancing act

Injecting the correct mixture of air and suitably prepared coal into the furnace in the right amounts, in the right location, and at the right time is the key to optimizing boiler efficiency, reliability, fuels flexibility, maximum capacity, and low stack gas emissions. This sounds easy in theory, but it’s much more difficult in practice given all the seemingly uncontrollable variables in the process.

However, pulverizer and related problems lend themselves to a structured analysis approach. There’s an old proverb that asks, How do you eat an elephant? The answer: One bite at a time. The same wisdom applies to a pulverizer tune-up (see sidebar).

Figure 2 shows the burner belt and furnace of a typical boiler and illustrates the short residence time, typically less than two seconds, that a coal particle has to complete combustion before impinging, and perhaps sticking, on a superheater or waterwall tube. If that particle continues to combust in the backpass, boiler efficiency is reduced, slagging and fouling increase, upper furnace gas temperatures are elevated, and emissions may increase.

2. In the zone. A fuel particle has less than two seconds to complete combustion before entering the superheater section of the boiler. Source: Storm Technologies Inc.

For example, pulverizer mechanical tuning and airflow management must work hand in hand to exploit the NOx-reduction potential of a boiler. Experts estimate that about 70% of the NOx produced from a pulverized coal–fueled boiler originates with the fuel-bound nitrogen. Nitrogen, usually between 0.5% to 1.6%, is usually a very small component of the fuel’s ultimate analysis but is the source of most of the NOx produced.

A fine performance

Improved fuel fineness, achieved only when pulverizers are in top-notch shape, leads to improved fuel distribution and greater surface area on each coal particle, making it easier for the fuel-bound nitrogen to be released in the burner devolatilization zone. Remember, fuel and air mix at the burners. Larger, coarse coal particles have higher momentum when entrained in air at a certain velocity and are more easily stratified than finer coal particles that have less mass and, thus, lower momentum.

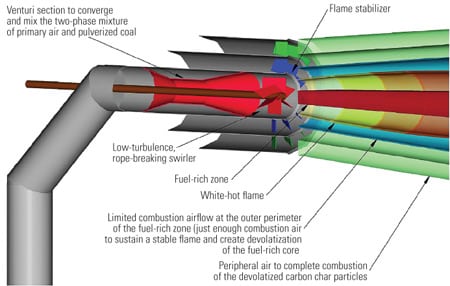

Moreover, as coal particle size is reduced, the available furnace residence time is more effectively used to complete carbon char burnout before the actively burning products of combustion enter the superheater section of the boiler. This is especially important with typical low-NOx burners (see Figure 3) and internally staged combustion.

3. Magic air mix. Modern burners stage the combustion of coal fuel particles to reduce NOx formation, but they increase carbon in the ash, which is an indicator of a loss of combustion efficiency. Source: Storm Technologies Inc.

After coarse and fine coal particles are separated, the fuel and air balance is further complicated by imbalances in airflow. Typically, burner lines that receive the largest quantity of coarse coal particles have the lowest dirty air velocities. This is why clean air balancing to achieve equal resistance between fuel lines is critical. It is also why attempts at fuel line balancing with “in service” adjustable orifices are very seldom repeatable. In addition, improved fuel distribution allows for more uniform burning in the furnace and equitably distributed oxygen across the furnace. Finely distributed 45- to 50-micron with “zero” percent particles on 50 mesh (say 75 to 100 microns) coal exiting the coal nozzle contributes to a more symmetrical and well-defined flame shape and much improved furnace performance.

Reducing upper furnace slagging is also a major driver for pulverizer performance optimization. Fuel-rich or fuel-lean streams of combustion products can produce localized zones with reducing conditions in the upper furnace. Secondary combustion in the upper furnace can elevate the furnace outlet gas temperatures, and when those temperatures are combined with the chemistry effects of a reducing atmosphere, they can cause the ash to become soft or sticky at lower temperatures. That soft or sticky ash can contribute to severe slagging at the superheater inlet in the upper furnace. The furnace excess oxygen cannot be “reduced” when there are zones of the upper furnace that have near-zero excess oxygen.

Finally, my experience is that larger boilers that fire high-sulfur and high-iron fuels with poor coal fineness will experience higher rates of waterwall wastage.

If fuel fineness is so important, why aren’t coal fineness samples and fuel distribution measurements taken on a regular basis? Often I have seen plant maintenance overhauls scheduled based on tons of coal throughput, pulverizer motor operating hours, or even calendar month. Sometimes, pulverizers are overhauled without performing a full before-and-after pulverizer test.

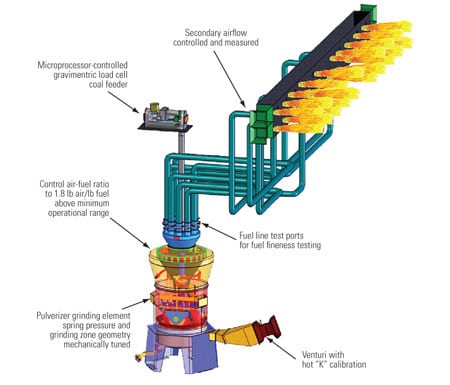

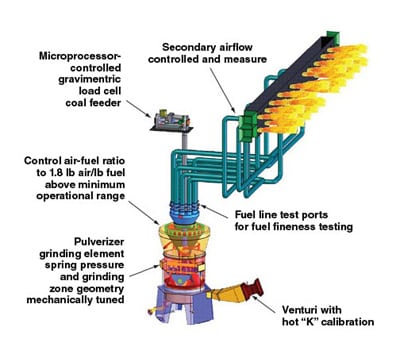

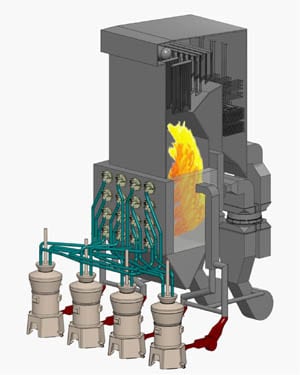

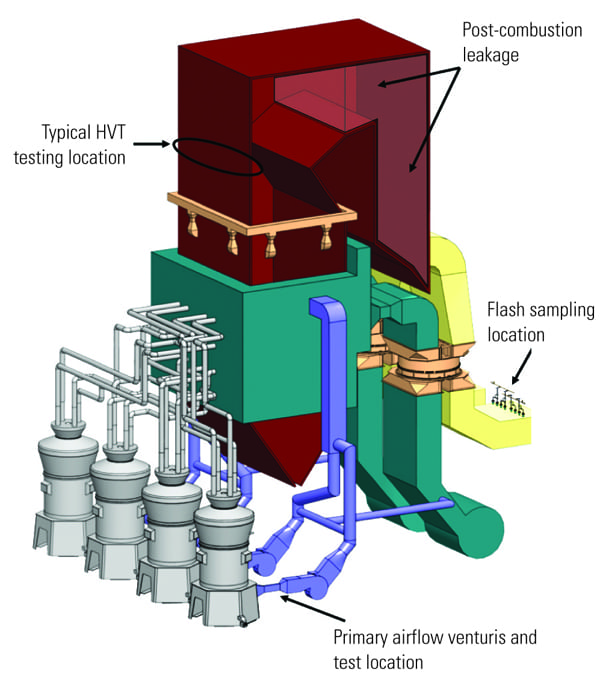

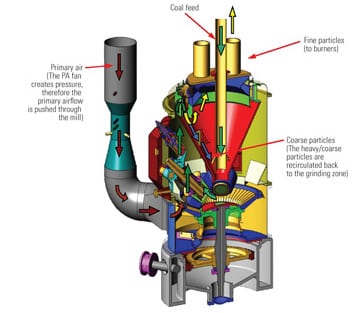

Instead, pulverizer fineness and fuel distribution to the furnace should be measured and, more important, used as the key metric for scheduled maintenance. When poor coal fineness is discovered, chances are good that fuel distribution will also be poor. Figure 4 illustrates how many of these hard-learned lessons are applied to a pulverizer system.

4. Pulverizer basics. The prerequisites for optimum pulverizer performance are good grinding element condition, satisfactory spring pressure, and of course, excellent mechanical condition. When these conditions are satisfied, the performance of the mill can then be optimized. Source: Storm Technologies Inc.

I have observed that many plants do not know what their fuel fineness is for months at a time, and when it is checked, it’s usually just a spot check of one pipe per pulverizer. Even when a sample is taken, many technicians aren’t sure what the measurements really mean in relation to good combustion practices.

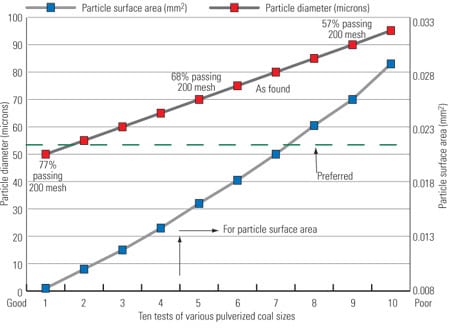

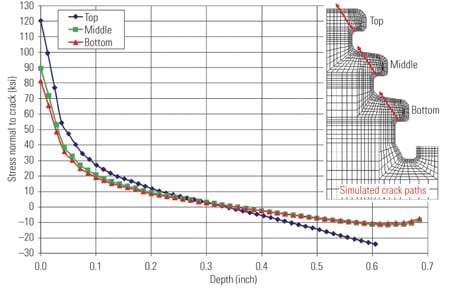

Figure 5 summarizes our experience over many years and many plant tests of the range of what we consider to be good to poor fineness. The figure depicts a rather large difference in measured micron sizing. Remember that coal fineness, or particle size, directly affects the time required for “carbon burn-out.” Improved fineness also improves fuel distribution to each burner line.

5. Making fine coal. The key to good combustion in the furnace is a pulverizer that produces coal with the right fineness. Source: Storm Technologies Inc.

Also observe that the variance from 60% passing 200 mesh results in a typical mean particle size of about 80 microns versus a preferable mean particle size of 45 to 60 microns—it’s a surface area difference of about 85%. Proper fuel fineness is absolutely necessary if carbon burnout is to occur in those first two seconds of residence time in the furnace.

Fine-tuning a pulverizer

The classifier can only supply sufficient fuel to the burners when the grinding zone is optimized for maximum pulverizer capacity. Pulverizer “capacity” is the amount of coal a pulverizer can grind at a given raw feed rate, to a given fineness, at a certain Hardgrove Grindabilty Index (HGI), and at a specific raw fuel size—typically crushed to ¾-inch plus tramp metal separation before entering the fuel silos. All four of these variables must be properly managed to achieve good pulverizer performance.

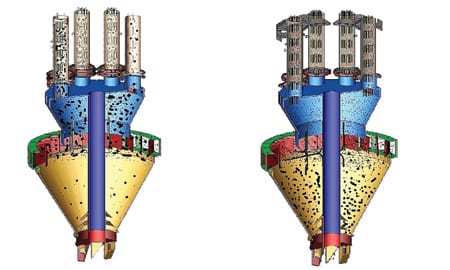

Classifier changes must be made to optimize both fuel fineness and fuel distribution. That is, classifiers can create good fuel balance provided the fuel lines are flow-balanced on clean air (Figure 6).

6. Balancing burners. Balancing burners begins with the classifier on pressurized pulverizers. The classifier has two purposes: to return course particles for regrinding and to balance fuel streams to each burner line. Poor coal fineness often yields poor distribution, because large coal particles and air mix to form a two-phase mixture that will not homogenize (left). Good fineness creates a homogenous and balanced mixture that behaves more like a gas than a two-phase mixture of air and fuel (right). Source: Storm Technologies Inc.

A typical pulverizer capacity correction graph is shown in Figure 7. Note that the capacity of a pulverizer originally designed for 45 HGI and 70% passing 200 mesh when operated with 40 HGI fuel at 80% passing 200 mesh will have a true capacity of about 70% of the base design. Of course, the penalty is greater if the pulverizer was originally designed for a typical eastern bituminous coal 40 years ago with an HGI of 50 to 60.

Figure 7 also clearly shows that fineness and hardness have a much more profound effect on pulverizer performance than moisture or coal feed size. This observation leads to an important conclusion: The common link for good furnace combustion and good pulverizer performance is fuel fineness, and that’s why we believe a properly tuned pulverizer that is capable of delivering rated fuel flow with the fuel fineness essential for good combustion is critical for optimum plant performance.

7. Predicting pulverizer performance. Four key parameters must be considered when assessing the performance of a pulverizer: fuel feedsize, fineness, moisture, and Hardgrove Grindabilty Index. Often pulverizers are called to perform far above their true capacity. Source: Storm Technologies Inc.

An optimum air/fuel ratio is also critical for achieving best fineness and best furnace performance. Pulverizer throats that are oversized are often compensated for by raising the primary airflow above the optimum 1.6 to 1.8 lb air/lb fuel range to minimize coal rejects. Although high primary airflow will reduce coal rejects, it does so at the detriment of coal fineness, fuel distribution, heat rate, upper furnace slagging, and furnace NOx production (Figure 8).

8. Sampling coal fineness. A typical sampling methodology uses an isokinetic coal sampler to determine if the coal pipes are properly balanced and if the coal is ground to adequate fineness. Source: Storm Technologies Inc.

Switching from an eastern coal to PRB coal entails much more than just getting a good price per ton for lower-sulfur coal. PRB coal can cause problems from the pulverizer through the furnace if the plant’s pulverizers are not up to the task. Many plants have switched to PRB only to experience much higher furnace and backpass slagging and fouling, which then prompts them to add more sootblowers and water lances in an effort to keep furnace surfaces clean. Chances are their problems are not with the furnace or the new coal but rather are the result of a poor tradeoff between pulverizer capacity and fuel fineness that was made to minimize the capital cost of the fuel switch.

—Richard F. (Dick) Storm, PE (rfstormsea@aol.com) is senior consultant for Storm Technologies Inc. and a POWER contributing editor.