This year’s ELECTRIC POWER Exhibition will feature the latest technologies and services from approximately 500 companies. Get a preview of some of the exhibitor offerings here. For the entire offerings, you’ll have to visit the show floor in Chicago this May. (You’ll find all the event information here.)

This exhibitor preview is arranged alphabetically by company name (in bold). If you know the name of the company you’re looking for, or to find a particular type of product, search this page by keying Ctrl-F (PC) or Command-F (Mac) and then typing the keyword(s) in the box at the bottom or top of your browser window.

A

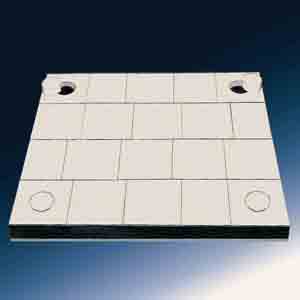

Wear Protection Systems

Abresist Corporation, a Kalenborn Company, introduces two new KERAFLEX wear protection systems, consisting of ALRESIST® high alumina ceramics or KALMETALL®W hard overlay welding plates vulcanized to a steel base. These systems are well suited where high abrasion and impact occur in combination. Maximum operating temperature is 176º F/80º C.

KERAFLEX reduces noise and is especially well suited for use in transfer chutes in belt conveyor systems and impact zones in bunkers and silos. These wear protection systems are produced in standard panels, up to 20” square, with welded studs or countersunk bolting attachments. KERAFLEX-KRM consists of ALRESIST high alumina ceramics with a tile thickness of ½” or 1”. The thickness of the rubber is determined by the severity of the impact. KERAFLEX-WRM consists of KALMETALL-W hard overlay welded plates, rubber and steel. KERAFLEX-KR, with 1/8”- to 1/2”-thick ALRESIST tile and a rubber backing only, provides for a flexible lining that is glued in place.

The Ultimate 3D Flow Measurement System

The 3D Probe Data Acquisition System (3DDAS™) sets a new standard for volumetric flow measurement systems for use in stack/RATA testing, fan outlet ducts, mill inlet ducts, and general ductwork. It is fully compliant with EPA Methods 2, 2F, 2G, and 2H and weighs just 22 pounds.

The 3DDAS boasts the ability to secure the most accurate measurements possible. Gone are the days of “sight weighted averages.” The 3DDAS takes 1,000 readings per second and calculates averages instantly. This is achieved with 3DPROBE™, state-of-the-art software that simplifies and expedites the testing process. It automatically generates test configuration information, records data, completes error checks, and outputs reports detailing velocities, pressures, temperatures, and flow rates.

Designed and built by Michigan-based Airflow Sciences Corporation, the 3DDAS also features a rugged industrial NEMA 4/12-rated computer, 16-channel and 16-bit data acquisition board, touch screen navigation, and wireless remote transmitter interface.

Utilizing Hot-Dip Galvanizing In Alternative Energy Projects

The American Galvanizers Association is pleased to announce the release of Sustainable Solutions for Corrosion Protection in Alternative Energy, an informative publication (available at www.galvanizeit.org/publications) detailing research regarding the strength and sustainability of hot-dip galvanized steel in the alternative energy market.

Sustainable Solutions explores how utilizing hot-dip galvanized steel in biofuel, wind, hydroelectric, and solar structures not only protects them from the effects of corrosion but also is highly sustainable and earth-friendly. Highlighting the inevitability of corrosion, this publication stresses the importance of making intelligent environmental and economic decisions, supported by real-life case studies from each sector of the alternative energy market. It also explains how the natural, recyclable zinc coating created in the galvanizing process will provide superior corrosion protection without requiring the costly carbon footprint of maintenance.

Increased Emissions Reductions

APTECH CST has developed a new very affordable technology (patents granted and pending) that will achieve better than 70% reductions in SO2 and NOx. If needed, reductions of more than 90% can be achieved with companion technologies such as low-NOx burners for NOx and small polishing scrubber for SO2. Reductions approaching 100% can be achieved for SO3 and chlorides. A significant reduction in mercury is expected and should exceed 90% using a bag house. Slag formation in the upper furnace and convective pass can be eliminated or dramatically reduced.

The capital and operating costs for the combined technologies are less than 8% of the cost of a scrubber and SCR, making them especially attractive because no large external structures required. Parasitic power is less than 0.5%.

Multi-Barrier Seal for Troughing Belts

Arch Environmental Equipment Inc. announced in January the release of the Talon® Seal, a skirt seal that utilizes the “more is better” theory. Manufactured with wear-resistant EPDM rubber, the Talon Seal minimizes belt friction using a multi-barrier seal design to guard against fugitive dust and spillage. The unique design includes a flexible heel and toe that auto-adjusts to belt sag and troughing angles maintaining a consistent, spill-proof seal. Resistant to ozone, weather and UV factors, the highly durable Talon Seal withstands temperatures up to 250° and is available in continuous lengths up to 600 feet.

Consistent with Arch’s goal of providing products that are simple to install, use, and maintain, this seal is easily installed using existing clamps and automatically conforms to the dynamics of any toughing conveyor belt without maintenance. Arch Environmental Equipment is a manufacturer and distributor of a wide range of mechanical and electrical products designed to improve the efficiency and safety of conveyor belt systems.

Bulk Conveyer Components

ASGCO Manufacturing Inc. is a leading manufacturer and service provider of proprietary bulk conveyor components that enhance bulk material-handling performance. We use proven products and technologies to provide our customers with solutions to their conveyor material-handling problems.

Essential attributes of present and future growth are the following:

• Develop productive cost-effective and technologically advanced, safe and reliable products specifically for the bulk material-handling industry.

• Establish a national and international network of local distributors that are selected based on their expertise in the conveyor material-handling industry and their commitment to 24/7/365 customer service.

• Provide assistance to customers that require specific application advice, customized products, or fabrication from installation through ongoing services with tailored maintenance.

• Actively continue to provide our distributors and customers with conveyor-training programs.

• Maintain a safe working environment for our employees.

B

Precast Concrete Trench Systems

An alternative to direct burial, Con-duct offers you a modular or one-piece concrete encasement that enables you to protect your cables or pipes from light pedestrian traffic or heavy truck traffic. Barkman Concrete’s design allows for future expansion and the flexibility to create angled corners, tees, and 90 degree corners, if needed.

Various options include unistrut inserts, weld plates, cable support blocks, grounding clips and divider panels to meet the needs of your application. Our support staff will provide you with technical data and detailed drawings as well as consultation services while the product is being installed. Standard, easy-to-remove, concrete covers are available along with lightweight GFRC lids, both giving superior protection and easy access to your electrical or mechanical system without having to resort to excavation.

Online Ash Analyzer

Berthold Technologies, well-known as a manufacturer of non-contact, non-intrusive measurement systems, has launched the newest generation of its ash analyzer – the LB 421 AshAlyzer, which measures the process online and in real time. Due to the real-time availability of ash content and calorific value, loading, unloading, production and preparation processes can be optimized. The supply of consistent coal quality is therefore guaranteed, which leads to significantly increased efficiency.

The modular concept of the AshAlyzer allows an easy application to the individual needs of customers’ measurement requirements. In addition to the analysis of ash content and flow rate using the tried and tested gamma transmission method, the energy and moisture content of coal can be determined by integrating an additional microwave measurement system. Features such as high detection sensitivity and stability ensure high reliability and accurate measurement results. The AshAlyzer has the industry standard IP65 with an easy-to-use touch screen operator interface, making it ideal for use in the coal industry.

Electric Power Technology Courses

Bismarck State College’s National Energy Center of Excellence offers online and classroom training for the energy industry. Associate in Applied Science (AAS) degrees can be earned, or courses can simply be taken for professional development and training. Classes are available in Electric Power Technology (distribution), Electrical Transmission Systems Technology (system operations), Power Plant Technology, Process Technology, or Nuclear Power. In addition, a Bachelor of Applied Science degree in Energy Management is available entirely online.

The classes are offered in a convenient block-style format, giving students the opportunity to complete a class in three to six weeks. The National Energy Center of Excellence is also known for its non-credit offerings such as apprenticeship programs, customized training, and NERC CEH courses.

Advanced Silicon Carbide Products

Blasch Precision Ceramics InVinCer by Blasch™ lines of advanced silicon carbide products deliver superior wear resistance for power generation applications. Blasch’s new reaction bonded silicon carbide (SiSiC) offers excellent wear, chemical, oxidation, thermal shock resistance, and the highest thermal conductivity to its maximum use temperature of 1,380°C. Available products include burner nozzles, pump components, mechanical seals, micronizers, and cyclones. Custom shapes are also available upon request. Highly abrasive wear and corrosion applications include FGD nozzles, burner liner blocks, pipe bend liners and other highly abrasive power generation applications.

Blasch’s recrystallized, RSiC, silicon carbide offers very high strength, excellent thermal shock, oxidation, and abrasion resistance to its maximum use temperature of 1,610° C. Available products include burner nozzles and specialized structural members, as well as custom shaped parts.

Boro-Block Borosilicate Stack and Duct Liner

Blome International is pleased to announce the addition of Boro-Block Borosilicate Stack and Duct Liner to its product line for FGD service. Boro-Block has many years of International success and has been specified and used by several U.S. utility companies in the past year. Not only does the Blome system outperform competitive materials, but it also is covered by a full 10-year warranty backed by a domestic insurance carrier. Boro-Block is suitable for use on steel, concrete, or brick substrates and could minimize loss in the event of a fire.

Blome International is a U.S. company with over 35 years of proven performance in the power industry. Our coatings are formulated and manufactured in house to maintain the highest level of quality on the job.

Wood-Handling Expertise

For the past 20 years the BRUKS Rockwood team has been developing and supplying materials handling solutions for customers who process and burn wood residue. The demand was initially centered on pulp and paper producers who had the desire to efficiently turn process waste into fuel. As the energy market has evolved this desire has expanded from the pulp mills into a variety of different arenas.

Today, demand for such solutions ranges from gas-fired boiler operators to producers of wood-derived fuels such as pellets. Most of these systems can be broken into three distinct segments: materials handling, production, and delivery. The BRUKS group focuses on the materials handling segment or the front end. In this area the materials are received, cleaned, sized, stored, and then delivered to the production island. A recent example of such a project is Green Circle Bio Energy located in Cottondale, Florida.

C

High-Density Ceramic Linings and Steel Fabrications

Headquartered in St. Louis, Missouri, C.L. Smith Industrial Company is a family owned business specializing in solving wear problems for industry. For over a quarter of a century, our fine reputation has been built on quality, service, and customer satisfaction.

We provide services and materials to improve reliability and service life of equipment and systems that are subjected to wear damage caused by abrasion or corrosion. Our materials include high-density alumina ceramic, silicon carbide, ceramic loaded epoxies, tungsten carbide, RTV silicone, and epoxy adhesive.

These materials can be shop or field installed in assemblies you provide to us or fabricated in our shop to your specifications and requirements. Most of these products are available for installation by you; however, some applications may require that we install the products in order to insure they will provide the service life you need.

Shotcrete for Boiler Cyclones, Furnaces, and Ash Hoppers

Christy Industrial Services is the leader in installation of shotcrete refractory for power generation, offering speed, safety, performance, and cost competitiveness:

• Installation time is reduced by over 50% vs. traditional ramming and gunite methods

• We set records for turning around your boiler

• Fewer people on site = fewer injuries

• Shotcrete is ergonomically safer than pounding plastic or guniting

• Shotcrete has four times less rebound, waste, and dust than guniting

• Other trades can work side-by-side with us due to low dust

• Our shotcrete materials have superior physical properties to ram or gunite

• Our customers are seeing at least double the life they traditionally get with gunite or ram plastic

• Shotcrete can be walked upon within minutes of shooting with no risk of damage due to foot traffic, scaffolding, etc.

• No one has installed more shotcrete in power than Christy

“Superheater” Vaporizers for Alternative Energy Systems

Chromalox, a leading manufacturer of electric heat and control products, has improved the heating capability and corrosion resistance of its horizontal electric vaporizers to create “superheater” technology to support production of materials for alternative energy systems. The enhancements allow the production process to vaporize materials rather than heating them in a furnace.

Chromalox horizontal electric vaporizers are designed to transfer heat at high temperatures and low pressures and are pre-engineered, pre-wired, and pre-piped for flexible, dependable and efficient operation. The recent enhancements to the technology open up new applications for these vaporizers, including hydrocarbon vaporizing.

Concrete Construction

The COMMONWEALTH Power Group of Companies is a recognized worldwide leader in the design and construction of power plant equipment, specializing in reinforced concrete chimneys, steel stacks, combustion turbine exhaust systems, and maintenance and repair services. Specifically, our products include the new construction of jump-formed and slip-formed reinforced concrete chimneys, dual-wall and single-wall steel stacks, HRSG stacks, combustion turbine exhaust stacks, tower-supported structures, incinerator stacks, architectural stacks and finishes, FRP and steel liner systems, and maintenance and repair services for all types of industrial concrete and steel structures. We serve a wide range of clients in power generation and other major industries both in the United States and around the globe.

High-Pressure Components

Come visit CTI Power (a division of Chicago Tube and Iron) at our new plant, which started production December 8, 2008.

EASYchange Online Removable Brush Holder

Cutsforth Products’ founder, Dave Cutsforth, has discovered that most problems that occur in the generator doghouse (including carbon deposits in brush box, poor terminal connections, brush binding in the holder, poor spring tension, and brush box erosion) can be traced to the brush holder itself. Any of these problems can lead to collector ring and commutator damage, poor brush life, possible catastrophic damage, and/or forced outages. The Cutsforth EASYchange Brush Holder System was designed to address each of these problems keeping you online and on time.

There are over 4,000 EASYchange brush holders operating without a single failure. See why the United States’ second-largest producer of power is in the process of retrofitting 50+ generators with EASYchange. Our holder addresses the seven most common problems with brush holders and rings. Imagine having one brush, one brush holder, and one mount for all units in your company plants, regardless of the foreign or domestic generator manufacturer.

D

Managed Maintenance Solutions

Day & Zimmermann Power Services (DZPS) would be pleased to meet with you at the 2009 ELECTRIC POWER Conference. This major industry event offers us a great venue for engaging in a dialogue about your power plant maintenance challenges, with a focus on how we can help accelerate your success in this critical area of your business.

In the power generation value chain, no other company provides the breadth of services, industry experience, strategic vision, and excellence in execution delivered by Day & Zimmermann. Our suite of innovative Managed Maintenance SolutionsSM is specifically tailored to be a “one-stop shop” for all of your power generation maintenance and modification needs. DZPS is comprised of Day & Zimmermann NPS and DZ Atlantic; combined, we are the largest O&M contractor in the power industry, according to the Engineering News-Record 2008 rankings. Our full-service offering includes: maintenance, modifications, construction, condenser services, valve services, fabrication & machining, radiological services, asbestos abatement/insulation, turnkey scaffold services, painting and coating, and professional staffing.

Planetary Mixer

DustMASTER® Enviro Systems introduces the first planetary mixer designed and built in the U.S.A. Developed for fly ash, bottom ash, and general industrial waste mixing, it utilizes a unique counter-current action to achieve a homogeneous mix in 60 seconds for most applications. With capacities from 4 to105 cubic feet, it delivers high quality and productivity for utilization or disposal needs.

E

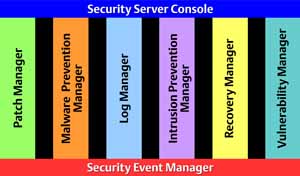

Ovation Security Center

The Ovation® Security Center from Emerson Process Management makes it easier for Emerson’s power generation customers to manage the execution of cyber-security measures related to compliance with the North American Electric Reliability Corporation Critical Infrastructure Protection standards. The Ovation Security Center is tightly integrated into the company’s industry-leading Ovation expert control system. The Ovation Security Center’s centrally located console streamlines management of the following security functions:

• Security event collection and threat identification

• Patch deployment and audit

• Malware detection and prevention

• Event log storage and reporting

• Intrusion detection and prevention

• Data back-up and recovery

• Vulnerability assessment and management

The Security Center’s event management capability provides a centralized event collection, event correlation, and threat identification function for security-related events in an Ovation control system. Security events are collected from each network device, including network intrusion detection systems, firewalls, routers, switches, servers, workstations, controllers, and Security Center application modules. Critical security events that require plant personnel intervention are forwarded to a notification function, such as the Ovation alarm system, an e-mail or pager.

Simpler Level Indication

The Endress+Hauser FMP45 Guided Wave Radar is already recognized as an excellent device for high pressure/temperature level measurement. However, with the Endress+Hauser Gas Phase Compensation enhancement, you can confidently place this unit in even more demanding applications. The Levelflex FMP45 with Gas Phase Compensation is the only guided wave radar that automatically adjusts for gas phase error, even in variable operating conditions. By utilizing a known reference point, the Levelflex FMP45 detects the gas phase error and corrects for it. This function is seamless and undetectable to the operator. The result is consistent and highly accurate level measurement.

You can install the FMP45 in your existing displacer chamber to minimize your downtime or include it on newly designed vessels. With no moving parts and Endress+Hauser reliability you will have a nearly maintenance-free level indication solution.

Intensive Use Chairs

Ergonomic Office Chairs Co., a division of United Group, Inc. announces the latest addition to the IRONHORSE 24/7 Intensive Seating line, the 1000HDC and 4000HDC.

Born out of the heavy equipment industry, the IronHorse HD Series 24/7 chairs are built like a Sherman tank but feel like you’re seated in a high-end luxury automobile. The 1000HDC and 4000HDC feature a high backrest design that contains an inflatable air lumbar support to ensure comfortable seating for prolonged periods of time. The anatomically contoured cushions are engineered for maximum memory, zero pressure points, and are supported by a robotically welded heavy gauge tubular steel frame with a positively locking backrest. Fitted with a polished cast aluminum base, the 1000HDC and 4000HDC will support a user up to 400 pounds.

Self-Cleaning Suspended Electromagnet

Eriez will exhibit a rugged 7000 Series Self-cleaning Suspended Electromagnet with Armor-Clad belt. Such SE magnets remove damaging tramp iron from coal and other materials conveyed in heavy burden depths on flat conveyors, vibratory feeders or chutes. All Eriez Suspended Electromagnets feature an exclusive external oil expansion tank that has helped prevent coil burnout on thousands of Eriez oil-cooled electromagnets. Heat and moisture, the greatest enemies of electromagnets, are effectively controlled by the expansion tank, which ensures that the coils are always completely covered with cooling oil. Competitive units provide air space within the magnet housing, where damaging condensation forms when moist air seeps in through the pressure relief valve as the magnet cools. Eriez’ expansion tank traps this moisture and keeps it out of the magnet.

These magnets are fabricated from heavy-steel plate with a thick, manganese, steel bottom plate. Other design features include Class H insulated aluminum coils, Space–wound coils with non–deteriorating fiberglass spacers and insulating material. Eriez 7000 Series Suspended Electromagnets are also covered by a 60-month coil warranty.

Tube Stabilizer and Anchor System

EST Second Generation Tube Stabilizer Anchors are now available to complete the Pop-A-Plug® Tube Stabilizing System. EST’s Tube Stabilizers prevent vibration or damage caused by movement of fractured or damaged tubes in many types of heat exchanger units. Without stabilization of the damaged tubes, neighboring tubes can be damaged or destroyed.

The stabilizer extends from the tube sheet, through the fractured or damaged section of the tube, and through the support plate beyond the fracture. The system utilizes one of several optional types of support (rod or cable), EST Pop-A-Plugs® Tube Plugs, and the Second Generation Pop-A-Plug® Stabilizer Anchors. The new anchor design incorporates the benefits of the patented EST Pop-A-Plug® with the added feature of user removal being possible. This allows for the efficient reclamation of tubes when called for.

Flat Rotating Self-Lapping Disc Valves

How many maintenance hours are you losing as a result of repairing the same valves more than once a year in your coal fired power plant? Everlasting valves from Everlasting Valve Company have provided years of service life in dry abrasive applications, including fly ash and bottom ash slurries. The Everlasting flat rotating disc air cylinder actuated Bulk Material Valve or BMV (U. S. Patent 5,396,919) was designed for vacuum to 100 psig systems, including dense and dilute phase pneumatic conveying systems for transporter fill valve, discharge, vent applications, transfer lines, under baghouses, silos and dust collectors. Sizes range from 2” through 14”, including 5”; cast iron sizes 2” through 8” available from stock.

Innovative Penetration Boiler Seal for HRSGs

Heat Recovery Steam Generators (HRSGs) are an excellent way to capture more value from the fuel budget. But achieving the most from an HRSG requires that they be operating as efficiently as possible. To increase efficiency and reduce maintenance cost, power plants are embracing a new generation of boiler penetration seals: slider seals that can significantly lower energy loss while reducing the maintenance load and risk of unplanned outage.

One new slider seal, the PS Seal® from Expansion Joint Systems, uses a floating ring design with patented stainless steel flow-reducing seals in contact with the penetration pipe outside diameter and lateral movement plates. The seals are compressed on assembly to provide minimal gas leakage during operation. As particulates build up in the seal and further restrict passage of gas, the gas leakage in the seal increasingly reduces over time. The stainless steel wire mesh seal can be replaced easily during shutdowns, eliminating the need to replace the entire unit. Because these seals may be disassembled and repaired without cutting metal piping or welds, there is no need for specially trained welders to install the replacements. Standard sizes, 4”to 24” nominal diameter, are currently available and will accommodate axial movement lateral movements.

F

Controlled Flow Material Transfer Systems

Controlled Flow Material Transfer Systems™ (CFMTS®) from Flexco Engineered Systems Group is designed to enhance overall conveyor system uptime and productivity. Flexco’s CFMTS are designed to control flow of material through a transfer by keeping material in a continuous stream throughout the transfer. The geometry of the system is designed to accurately control velocity and direction of the material stream contained within it, so the material stream stays together with all fines and particulates entrained in the stream. CFMTS is characterized by:

• Low angles of impact

• Low material degradation and dust generation

• Low noise levels and wear rates

• Soft and central loading on the receiving belt(s)

• Being spillage and maintenance free

• Not requiring impact beds

• Not sensitive to conveyor orientations

• Low maintenance operating costs

• Reduced associated conveyor component wear

Flexco’s bucket diverter design permits simultaneous splitting of the material stream between two discharge legs of a diverting system. Furthermore, the proportion between the legs and/or the amount of material flowing down the legs can be controlled and automated, provided there is a system for measuring the amount of flow, such as a belt scale, coupled with a PLC or similar control system.

Fly Ash Handling System

FLSmidth’s A2P™ Fly Ash Handling System reduces capital cost by up to 50%. The Airslide™ Conveyor to Fuller-Kinyon™ Pump Fly Ash Handling System offers these benefits:

• All hoppers empty, all the time

• Virtually maintenance-free

• Continuous ash removal from collection hoppers

• Only two moving pieces between collection hopper and storage

• Continuous conveying to storage

Fly ash continuously discharges from all dust collector hoppers simultaneously. Ash becomes fluidized within the Airslide Conveyor and flows rapidly down the slope via gravity. Fluidization air is heated to further ensure proper ash flow to the Fuller-Kinyon Pump. The pump acts as a “line charger,” injecting the ash into the pressurized convey pipeline while acting as an airlock between the conditions in the dust collector/Airslide conveyor and the conveying system. The Fuller-Kinyon pump conveying system uses carbon steel straight piping and hard iron sweep fittings. A simple bin vent filter is required at the destination silo to vent the conveying air.

Enhanced NOx Reduction

Fuel Tech completed the acquisition of Tackticks and FlowTack in October 2008. Volker Rummenhohl brings 23 years and 55,000 megawatts of experience in the design, evaluation and performance of SCR systems for NOx control. This enhances Fuel Tech’s process design capability of its NOxOUT CASCADE system, which is enhanced SNCR with a downsized SCR system. Services include ammonia injection grid tuning and catalyst management help optimize catalyst performance and life. FlowTack brings expertise in physical experimental models and computational fluid dynamics models. Models help clients optimize performance in flow critical equipment, such SCR systems, flue gas desulfurization scrubbers, electrostatic precipitators, exhaust stacks, and sorbent injection systems. Product offerings include flow corrective devices, such as turning vanes, static mixers and its patent pending Graduated Straightening Grid.

On January 6, 2009, Fuel Tech completed the acquisition of Advanced Combustion Technology. Product offerings include ultra low NOx burners, burner upgrades, and over-fire air systems, with experience on over 70 installations. Services include airflow testing, coal flow testing, and boiler tuning and consulting services. High Energy Reagent Technology HERT or NOxOUT® SNCR systems can be combined with burner and over-fire air systems for total NOx reductions up to 85%.

Babbitt Bearing News

Fusion Babbitting Company Inc. news includes:

• Addition of a state of the art metalizing booth to rebuild the OD fit on bearings. We now are spraying, steel, cast iron, and bronze material.

• We have increased our machining capabilities by purchasing a new 42” swing lathe, setting up a new 36”centrifugal casting machine, and hiring six new employees for our 2nd shift operation.

• Redesigned company brochure and printed for distribution

• Green participation: We installed all new plant and office energy saving lighting this year.

• In March 2008 Milan Juric joined our staff as general manager.

• We are again offering babbitt bearing educational seminars.

• We will participate in 5-6 trade shows in 2009.

G

Spring-VISCODAMPER Support of Machinery

The GERB Spring-VISCODAMPER® element is a widely applied device for the elastic support of power plant equipment and piping around the world. Its elements: protect equipment and structures during seismic events, reduce stress in the machine and foundation due to differential settlement, reduce sub-foundation dimensions, and reduce vibration transmission. Applications include the spring support of turbines, condensers, boiler feed pumps, coal mills, fans, diesel gen sets, and transformers.

Established in 1908, GERB Vibration Control Systems has unique solutions for the vibration isolation of machinery, buildings, and power infrastructure. GERB offers consulting services, design, manufacturing, and installation of vibration isolation systems consisting of compression steel spring elements and VISCODAMPER. GERB has continued to develop this technology, solving complex dynamic problems in many fields of application.

Variable-Speed Tube Cleaner

Goodway Technologies Corporation is proud to introduce the RAM-5SFVS Variable Speed Ream-A-Matic® Tube Cleaner. With a shaft feed rate of up to 3′ per second, it is the machine of choice among contractors and facility managers with large tube bundles. As the cleaning tool loosens debris, the shaft casing provides a steady stream of water, flushing out debris and restoring system efficiency. While the Speed Feed gun lets you control the direction of shaft rotation as well as the flow of water, the variable speed function allows you to control both the brush rpm and the feed rate. It is ideal for removing both soft and hard deposits from smooth bore as well as internally enhanced tubes/pipes 1/4"-1" (6.4-25.4mm) I.D.

Specifications:

• Flexible shaft speed: Variable, up to 862.5 rpm

• Speed-Feed gun rate variable, up to 3′ per second

• Speed-Feed gun push/pull force: 50 lbs

• Motor power: 1 HP

• Input power 12 amps, 115 V, 60 Hz AC

• Optional: 12 amps, 115 V, 50 Hz; 6 amps, 230 V, 60 Hz; or 6 amps, 230 V, 50 Hz

• Dimensions (excluding gun and guide hose): 37" high x 20" wide x 17" deep

• Weight: 75 lbs net dry

Submersible Drainage Pumps

In Grindex’s new generation of submersible drainage pumps, wear resistance has been at least tripled by preventing abrasive particles from reaching the vulnerable parts of the pump. The newly designed hydraulics section with its closed impeller is dramatically reducing the performance drop caused by long-term wear. This makes the new pumps capable of operation in really demanding applications with maintained capacity. The new design also allows easy adjustment of the impeller to regain optimal performance. It simplifies the service and ensures both longer lifetime and stable dewatering during the whole pump life.

The new pumps have an ergonomic design that makes them easier to handle. We have introduced a new cartridge seal, simplifying service routines because it can be fitted with a simple movement. And being able to adjust the impeller with a single screw simplifies service further. The new pumps still feature the SMART Grindex electronic motor guard. These features prevent overheating, incorrect rotation, and single phasing. SMART contributes to longevity and high reliability. Another refinement is the air valve. In the event of dry running, the impeller automatically functions as a fan to cool the pump motor, bearings and seals when the air valve releases the hot air.

H

Equipment Management Software

HECO, Inc. Industrial Service Groups of Kalamazoo, Michigan, has just introduced the newest generation of its “equipment management” software, uniquely named “TracRat®.” This program was developed to have identified savings through repairable asset inventory reduction and repairable asset repair cost reduction.

Originally born over 25 years ago as a combination of 1980s paperwork and computer technology, the first generation of HECO’s “Motor Management” effort served a collective group of seven automotive plants in western Michigan. The goal was to store electric motor critical spares, share electric motor inventory between plants, set electric motor inventory reduction goals, and reduce the cost of repair for the plants at a measurable pace. With the advent of the PC-based World Wide Web, HECO began to develop TracRat® as a user-friendly information technology tool that could not only perform the day-to-day motor management functions but can also be easily adapted to fit any repairable asset. For all repairable assets, TracRat® can track warranty recovery, track and report cause of failures, issue request for quotes, and generate a variety of charts to determine planning for future predictive maintenance procedures and repairs.

Advanced Energy Solutions to Reduce GHG Emissions

Honeywell’s Process Solutions business has introduced its Advanced Energy Solutions, a suite of process control, monitoring, and optimization applications designed specifically for industrial power generation facilities. The Advanced Energy Solutions suite allows industrial power and cogeneration plants to balance electricity generation demands with operational efficiencies and regulatory constraints. By implementing Advanced Energy Solutions, industrial power generation facilities will benefit from reduced heat rate and power production costs, increased effective boiler operating range, reduced greenhouse gas (GHG) emissions, optimized production capacity utilization, optimized transient states control, extended production asset life and reduced maintenance.

The solution fully integrates with the Honeywell Experion® Process Knowledge System, as well as other distributed control systems. Software applications available as part of the suite include Advanced Combustion Control, Plant Performance Optimizer, Master Pressure Control, Plant Performance Monitor and Tie-Line Control. These applications have common architecture, compatible interfaces, and can be implemented individually or as a completely integrated solution in order to maximize the process optimization benefit.

Integrated System Descriptions

HPC Technical Services has taken system descriptions to the next level and is excited to introduce the Power-Doc, which includes the following in one document:

• Interactive system description,

• Interactive P&ID,

• Interactive alarm response manual

• Interactive instrument loop diagram

First, HPC writes an equipment-specific system description, adds images of your equipment, and includes your P&ID completely redrawn in color. This colorized version has the same detail as the original drawings and is a definite plus when tracing system piping and/or troubleshooting system problems. Next, HPC adds links to the P&ID, images, and system description to allow the user to jump back and forth within the Power-Doc. The resulting Power-Doc is a great tool for operating/troubleshooting each system.

If an alarm occurs in the control room, operations personnel open the Power-Doc, select the appropriate Alarm Title, and immediately view a list of probable causes and probable operator responses. They can also select the P&ID on the screen and go immediately to a highlighted P&ID of the system in question or select the instrument on the P&ID and see an Instrument Loop Diagram that shows the instrument, the wiring, and calibration data.

I

Imbiber Beads

Award-winning Drain Protection Systems (DPS) from Imbibitive Technologies America are designed to allow rainwater to drain but automatically seal the leak path in the event of an oil release. Imbiber Beads®, used by the DPS, selectively remove organic liquids including PCBs from water. Imbiber Beads are discussed in the Design Guide for Oil Spill Prevention and Control at Substations, USDA-REA (RUS) Bulletin 1724E-302, the USEPA final rules for SPCC compliance, 40 CFR Part 112 (2002) as well as in the IEEE Guide for Containment and Control – IEEE Std. 980.

Imbiber Beads are the only true aBsorbent (ASTM F716) “engineered” for organic chemicals. They are not an aDsorbent and they are not a thickener/solidifier. Imbiber Beads will not dissolve in excess liquid. Water can not be absorbed by Imbiber Beads as they are hydrophobic. Imbiber Beads Imbicator® (changes color) Spill Maintenance Products (booms, blankets, pillows and packets) are also available for capturing and containing compatible organic chemical (fuels, solvents, mineral oil) releases.

Enhanced 3D Electric Field Solver

INTEGRATED Engineering Software, a leading developer of hybrid simulation tools for electromagnetic, thermal, and structural design analysis, has launched an enhanced version of its COULOMB 3D electric field solver software. Fast and accurate, COULOMB’s calculations include electric field strength, transmission line parameters, and capacitance. It is suitable for applications such as high-voltage shielding, transformers, insulators and bushings, transmission lines and lightning arresters.

COULOMB has always offered a successful integration of an effective calculating method with accuracy and an engineer-oriented approach. Powerful parametric solvers allow designers to automatically vary and experiment with geometry, materials and sources, reducing the tedious, repetitive task of fine-tuning multiple design parameters. Version 7.0 of the software includes features such as self-adaptive 3D Finite Element Method and a better use of memory. The self-adaptive 3D FEM feature has been significantly enhanced and is now quicker to converge with less iterations. The only practical limitation for this feature is the amount of RAM available on the workstation. The program can now solve larger FEM problems up to 10 times faster than previously.

Water Treatment

Itasca Systems and its parent corporation, H2O Innovation, have a solution for all of your industrial water treatment needs. Our talented team designs, builds, and services every Itasca water treatment system with a sense of commitment and dedication that is unparalleled in the industry. We are a custom manufacturer that can build a system to your exact specifications with versatility and innovation. Our engineers see our projects through to the very end, so you can always count on us to listen to you and help you through every phase, before and after the job is done. Whether you need a high-quality membrane system for your high-pressure boiler or a waste water system for your plant effluent, we have knowledge to share.

J

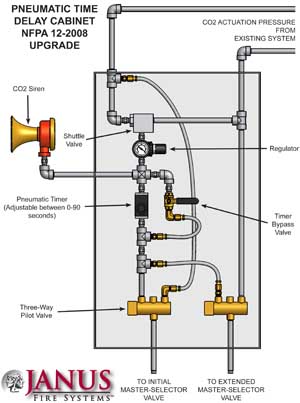

Fire Protection

Janus Fire Systems is an integrated supplier of fire protection products and services for the power generation industry. Janus Fire Systems designs special hazard systems using a variety of products. Carbon dioxide fire protection systems have been effectively used to protect base load fossil and nuclear plants, as well as combustion gas turbines for years. In an unprecedented move, the NFPA 12 committee mandated safety upgrades for new and existing carbon dioxide systems to be completed by December 31, 2008. The National Fire Protection Association’s (NFPA) Standard 12 has been the definitive guide for design, installation, and maintaineance of carbon dioxide systems since its adoption in 1929. Required system modifications include upgraded signage, lock-out valves, odorizers, and pneumatic discharge delay timers—all to reduce the chance of a carbon dioxide discharge in an occupied space.

The Janus Fire Systems engineering team reviewed existing low-pressure carbon dioxide systems with the focus of becoming compliant with the new standard. In the process, they designed a proprietary Universal Pneumatic Time Delay System that meets the requirements of NFPA 12, section 4.5.6.1. This preassembled unit can retrofit all brands of low-pressure carbon dioxide systems.

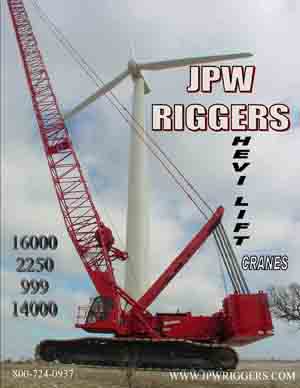

Crawler Cranes

JPW Riggers, Inc./JPW Structural Contracting, Inc., based in Syracuse, New York, have been servicing the industry since 1953. JPW Riggers offers one of the largest fleets of Manitowoc 16000 crawler cranes in the country, as well as Manitowoc 2250’s, 999’s and 14000 series cranes. JPW also offers a diverse selection of hydraulic, rough terrain, and all-terrain cranes.

JPW Riggers offers nationwide service. JPW Structural Contracting is an AISC certified steel fabrication and erection facility with a 120,000’ state of the art fabrication complex located in Syracuse, NY. JPW Structural offers the latest in CAD technology and steel fabrication equipment. JPW Erectors was the first steel erector in New York State to be awarded an ASIC certification in complex steel erection. JPW is number one in safety compliance.

K

Bearing Repair and Service

There are many reasons why bearings fail in rotating equipment. Failures occur from contaminants in the oil such as quartz and sand, metal chips, fly ash, and weld spatter. Bond failures occur from improper cleaning, dirt, gases, pour bonding techniques, oxides, reused or bad babbitt, etc. Cavitation erosion and corrosion are other means of failures. Fatigue failure is the cracking and fracturing of metals due to excessive cycling. There are other failure reasons such as overheating, electrical pitting, high-chromium damage, seizure from improper clearances and misalignment. There are many reasons that are recognizable and there are many that are very difficult to distinguish.

Kingsbury Repair & Service Division provides you with experienced personnel to help recognize problems and work out solutions. Kingsbury provides quality control unmatched in the repair industry. If we need to resolve a problem such as redesigning a bearing, eliminating or reducing shaft currents, increasing loading capability, installing temperature probes, or providing a field service engineer, we can handle it.

Key Interlock

Since 1932, Kirk Key Interlock Company has continually demonstrated its commitment to the key interlock industry. Now, we are introducing a new logo that symbolizes the company’s past, present, and future. Along with our dynamic new logo, Kirk Key Interlock Company will re-launch kirkkey.com to feature multilingual content and convenient, yet secure, access to your order information (i.e. shipping date, tracking number, etc.) as an extension of the professional and courteous customer service you have come to expect.

High-Pressure Screw Compressor

High-pressure screw fuel gas compressors (API-619) are now available up to the high-pressure range of 100 barG (= 1500 psig), allowing the high-pressure screw compressor to cover most of the areas traditionally handled by reciprocating compressors. This means that owners of gas turbine power plants can fully enjoy the higher reliability and long-term continuous operation with lower maintenance offered by the high-pressure screw gas compressors, without suffering from difficulties due to the frequent maintenance required by reciprocating compressors.

In addition to more than 250 sets of experience for all types of gas turbines, Kobelco has already delivered several sets of screw fuel gas compressors for GE LMS100 in the U.S. and Canada, which requires higher pressure fuel gas due to its high efficiency. The positive displacement screw gas compressor continues to offer the original great design benefits, such as higher reliability, lower maintenance, environmental friendliness, flexibility for changeable operating conditions, plus tremendous power saving by the slide valve mechanism. Kobelco higher pressure screw gas compressors can now bring even more benefits to gas turbine power plant.

Ring-Section Pump

Power generation stations play an important role in meeting today’s energy and environmental needs. KSB’s high-pressure ring-section pump is designed with state-of-the-art technology that will improve your overall plant performance while meeting these needs. The HGM is an environmentally friendly pump that requires no oil, no cooling water, and is essentially maintenance free. Together, these features give you a product that not only leads the field in quality, efficiency, and reliability but also keeps your energy and life cycle costs down.

L

Rotating Equipment Repair

L&S Electric works hard at keeping you working. With the current economic environment that we’re in, that core belief has never been more important. We offer comprehensive rotating apparatus repair capabilities regardless of brand. Our network of service centers feature complete diagnostic and testing capabilities for almost any type of rotating equipment. The L&S Electric name has become synonymous with recognized leaders in modernizing hydroelectric controls, with the best value in digital governors, automation, excitation, and digital relay protection systems.

The power service team provides complete service for all power system components, regardless of voltage, including troubleshooting, commissioning, turnkey installation, repair, calibration, testing, and system design. Our reliability service team specializes in custom predictive maintenance programs designed to detect equipment problems before they cause costly downtime. Using state-of-the-art technology and training, our reliability team can eliminate any future headaches that may cost you a fortune. With convenient locations throughout the upper Midwest and Canada, L&S Electric offers capabilities unlike any other company. From small motors to large hydroelectric generators, we offer unparalleled service. With total on-site and in-shop services available 24/7, L&S Electric is your complete source for all your service needs.

Lectrodryer Fast Degas CO2 Evaporator

The Lectrodryer Fast Degas CO2 Evaporator system allows for quick degassing of the generator while preventing lines from clogging due to ice forming as a result of CO2 expansion. The Fast Degas CO2 Evaporator has the ability to deliver 305 SCMH of CO2 to the help reduce the time and cost involved during outages by allowing the generator to be degassed and brought back online much more rapidly. This system also provides an important safety benefit by rapidly blanketing the generator with inert gas in times of upset conditions or emergency situations.

Portable, Multi-Process Power Source

Lincoln Electric’s new Power Wave® C300 is a portable, multi-process power source with high-end functionality, ideal for applications and materials where arc performance is critical, including aluminum, stainless steel, and nickel. The Power Wave C300 provides one machine for nearly every weld application, including production welding, construction, aerospace, automotive repair, general fabrication or a training environment.

The machine features Lincoln’s new PowerConnect™ Technology to automatically switch from 200 to 600 volts, 50 or 60 hertz, and single- or three-phase welding with no manual reconnect and a constant welding output. It also features:

• Patent pending technology that allows for automatic input voltage reconnection

• Advanced user interface customizable for multiple operators, processes, and settings

• Industry’s highest efficiency rating at 88 percent at 250A with a 0.97 power factor

• Standard Production Monitoring™ 2 software enables weld data to be monitored

• Durable and rugged case designed for harsh environments

The machine is IP23 rated and weighs just 91 lbs, making it easy to transport for off-site applications, and its Waveform Control Technology® provides superior arc performance and allows users to download applications free of charge from www.powerwavesoftware.com.

M

Eddy Current Inspection Technology

Magnetec Inspection, Inc. is the recognized market leader in the on-site inspection of tubular process equipment, high- and low-pressure feed water, tubular heat exchanging, and cooling equipment in the petrochemical, chemical, paper/pulp, and electric power generating industries. Our continuing emphasis is on supplying high-quality, eddy current, remote field, IRIS, and remote video inspection services to our customers on their heat and cooling exchangers.

Through our advancement in personnel training, product data development and R&D activities we will remain at the leading edge of technology and provide for our customers the most up-to-date, reliable, and quality inspection services that are available. Our capabilities not only encompass the inspection and analysis of eddy current data but also evaluation of the exchanger based on metallurgy selection, corrosion engineering, failure mechanism analysis, design, performance, and life expectancy.

Dust Accumulation Resistant System

Martin Engineering has designed a dust accumulation resistant system. MARTIN® EVO™ Conveyor Technologies eliminate flat surfaces where dust can accumulate. This new architecture is upgradeable to meet any future material handling challenges. MARTIN EVO Conveyor Technologies exceed safety, environmental, and design codes and regulations.

The majority of the components are track-mounted and accessible from one side of the conveyor, simplifying installation and maintenance. The patent-pending wear liners are mounted on the outside of the skirtboards for more efficient and safer installation, adjustment, and replacement. All of the components are designed to eliminate dust, maximize uptime, and minimize downtime and maintenance costs.

Linking Financial and Operational Systems

Companies have long been monitoring the operation of their assets and in parallel tracking the costs of their operation. However, for most companies the challenge lies in linking the financial and the operational systems. This linkage is now possible, enabling companies to tie the cost of their operation back to the actions and processes that contribute to the costs. Once this linkage is achieved, users can make decisions with full visibility into the bottom line impact of the decision.

Matrikon’s solution integrates data from the following types of systems into a homogeneous platform: financial data, maintenance work orders, reliability data, real-time time-series data, and calculated values (such as production costs in $/MWh, process cost, and lost market opportunity). Through this integration, users at all levels of the organization are able to see the impact of their actions on profitability and modify their actions or processes to improve company results.

Air Pollution Control Systems

McGill AirClean helps the power generation industry meet stringent emissions regulations with dependable, economical air pollution control equipment. Our acid gas control systems provide effective control using a variety of reagents to convert acid gas to chemical salt. Our spray-dry scrubbers utilize dual-fluid nozzles to spray finely atomized reagent droplets into the scrubber for excellent acid gas neutralization. We also engineer dry injection systems that use various types of alkali.

Our electrostatic precipitator designs are modular, which drastically reduces field construction time. The dry ESP uses needle/plate electrodes that are the most energy efficient in the industry. Our wet ESP is a horizontal flow design with multiple, independent fields for superior performance. Our fabric filter design utilizes a single removable top lid, where the entire pulsing system is lifted off an individual module with an integral crane for quick, unimpeded access to bags and cages. Our deNOx reactor for selective catalytic reduction systems can be manufactured in high-dust or low-dust configuration. The systems are flow-modeled and can achieve 90+% nitrogen oxides removal.

Multi-Point Lubrication System

The MEMOLUB® “Plug ‘n Lube”™ Multi-Point Lubrication System is a miniature central lubrication system. The system can be used to lubricate from 2 to 12 lube points. The Plug ‘n Lube system comes with a MEMOLUB Lubricator, distribution block and nylon tubing, prefilled with your selection of lubricant. Simply cut the tubing to the required lengths and plug them into the lubricator and bearings using the plug-in tube fittings that are supplied with the system. That’s it. The system is ready to go.

The programmable MEMOLUB uses low-cost, prefilled replaceable lubricant cartridges, available in three sizes, with a selection of over 300 lubricants. A variety of power options are available , from self-contained battery pack to external 12 or 24 volt power operating under external or PLC control.

Easy Coal Dust Clean-Up in Hard-to-Reach Areas

OSHA’s Combustible Dust National Emphasis Program now requires dust levels to be less than 1/32” (which is approximately equal to the thickness of a typical paper clip) due to combustible dust incidents/explosions. FoamKleen® portable cleaning systems safely keep coal handing facilities in compliance. FoamKleen can be used to reach high spaces such as roof beams, open web beams, tops of pipes and duct work, and other horizontal surfaces (as defined in OSHA Directive #CPL 03-00-008) where coal dust or other dust accumulates to stop the threat of explosions. The FoamKleen Systems also come with standard explosion-proof pumps.

By using air and/or water only cleaning systems, dust plumes are created, which is unacceptable under OSHA housekeeping standards. The FoamKleen agent encapsulates the coal dust and dirt that travels down the walls from the ceiling, girders and framework. The foam then carries the dust deposits directly to the floor. After the foam dissipates, coal fines and dust can be easily removed.

For over 33 years, Midwest Industrial Supply Inc. has improved customers’ operational efficiency and operation costs while achieving environmental integrity and compliance in a variety of industries.

Axle Trailer

Miller Transfer recently put into service a new 2008 Nelson 9-axle trailer. The trailer, coupled with Miller’s 4-axle tractor, creates a 13-axle tractor trailer combination, which has a “cargo” capacity of 160,000 lbs. This new state-of-the-art trailer offers the latest in “depressed well” technology. The trailer well assembles from 15 to 90 feet long and can accommodate shipments up to 19 feet wide within the well. The trailer has telescopic crossmembers that are hydraulically operated, thus requiring minimal assembly. This results in time and cost savings for Miller Transfer’s customers.

Reliable Isolation, Vent, and Drain for Severe HRSG Service

Severe service floating ball valves from MOGAS Industries have proven to be a dependable solution to demanding valve applications with a history of leaking. The MOGAS quick quarter-turn valve design has sealing components that are precisely mate-lapped with sharp leading edges on the metal seats that act as windshield wipers to wipe the ball clean with each operation. Also, the seats are protected in the open position.

Tight isolation is critical to allow the units to be able to sustain longer run times. Typical large bore MOGAS C-Series valve applications include: HRSG isolation with HP valves of F91 ranging in size from 12-18” 2500 ASME ; turbine bypass isolation floating ball valves of F91, 12-18” 2500 ASME; and sky vents available in F91 or F22 from 3-8” 2500 ASME. Good applications for the rugged but smaller RSVP MOGAS valves are HRSG drains and vents. These LP, IP, and HP installations are usually carbon steel, F22 or F91 valves ranging in size from 1” to 3” and 300 to 2500 ASME. Some key features of the RSVP include superior spray and fused coating, a double-keyed stem, deep stuffing box, mechanical precision stop, and stem with an integrated thrust bearing.

Complete Services for Electric Power Generation Projects

Mustang Engineering (“Mustang”), part of international energy services company John Wood Group PLC, offers complete services for electrical generation, transmission, and distribution projects, whether above ground linear or buried lines. Mustang couples a staff of experienced electrical engineers and designers with a pipeline field services group to complete all aspects of electrical transmission, utility interface, and substation projects. Electrical engineering can commence with the project’s conceptual phase and follow through project execution and startup. Pipeline field services include in-house specialists in right-of-way, environmental permitting, survey, pipeline engineering, construction management, and project management.

Mustang is an independent services provider to the global oil, gas, chemical, and manufacturing industries. Specializing in design, engineering, procurement, project management, and construction management, we offer these services through six business units: upstream oil and gas, midstream, pipeline, automation and control, refining and petrochemicals, and process & industrial. Mustangers number 5,000 worldwide, with offices in the U.S., United Kingdom, Australia, India, and the Middle East. U.S. offices are located in Houston and Fort Worth, Texas; Birmingham, Alabama; Monroe, Louisiana; Martinez, California; Atlanta, Georgia; Greenville, South Carolina; and Wilmington, Delaware.

N

High-Voltage Coils

The world’s largest independent manufacturer of high-voltage coils for generator replacement windings, National Electric Coil offers the most diverse range of options in engineered coil design in the industry. NEC makes coils and bars of all types: conventionally cooled coils and bars as well as inner-liquid- or inner-gas-cooled Roëbel bars. Unit size is no limit. NEC has manufactured windings for units over 1,000 MW. NEC also offers design options for both vacuum pressure impregnation (VPI) and B-staged tape insulation systems.

Along with its engineering expertise in high-voltage machines, NEC also provides aftermarket services for the repair, upgrade, and refurbishment of large generators and rotating exciters. Services include failure analysis, testing, high-speed balancing with running electrical tests, engineering design for unit modifications, and fabrication of replacement parts. NEC operations include manufacturing sites in Columbus, Ohio (turbogenerator rotor windings) and Brownsville, Texas (high-voltage stator windings), and a service facility in Columbus addressing a full range of electrical and mechanical issues for turbogenerator rotors. NEC also provides on-site services for generator rewinds, retrofits, and repairs.

Heat Exchange Cleaning Services

National Heat Exchange Cleaning Corporation (NHE) has been the power industry’s one-stop shop for all heat exchanger needs since 1995. With its patented, proven shell-side cleaning process combined with all services required to refurbish, restore, and rebuild heat exchangers, NHE leads the industry in customer satisfaction.

New services for 2009 include cooling tower cleaning and repair services for hyperbolic and mechanical cooling towers. Allied with the Merrick Group of Harleigh, Pa., which brings 25 years experience into the NHE arsenal of services, NHE is capable of meeting all your cooling tower cleaning, repair, and refurbishing needs. A full-service retubing shop is now operating within NHE and offers its customers the best in retubing services with full control over quality and on-time delivery.

Driver Safety Training

For over 30 years, National Traffic Safety Institute has remained the leader in traffic safety education nationwide. NTSI’s innovative approach to driving safety stresses personal accountability as the participants explore an interactive curriculum based upon proven behavioral modification principals. Some of the programs created include SAFER Driver, Van/High Profile Vehicle, CDL Refresher, Fire Department, and Law Enforcement Programs. NTSI recently completed Golf Cart/Utility Vehicle Program Online.

NTSI is pleased to continue providing driver training to the US Army as well as the Federal Highway Administration. The US Army has been a continued partner since 2005. Approximately 3,000 to 5,000 soldiers complete NTSI programs daily. As of August 2007, over 2.3 million soldiers have completed their assessments, of which four have been killed (two of whom were actually operating a motor vehicle). By providing a copy of their risk analysis, participants are able to discuss their planned trip, the risks involved, and how to control and mitigate those risks.

P

Contractor Safety

Need an auditable, standardized OSHA safety orientation for your utility contractors? One that provides awareness-level training and a secure database for records retention and look-up? Ready to eliminate redundant training as your mobile contractor workforce moves from site to site? As a utility owner, you understand the challenges of verifying contractor safety. You need an effective and cost-efficient way to ensure that your workforce is safety-ready before stepping on property. You need assurance that a consistent and timely message about the value of safety is reaching every worker.

PowerSafe Generation™ delivers what you’re seeking. We heard you say, “Our contractors’ safety matters too!” So, we brought together a representative group of utility owners and contractors to create PowerSafe Generation to meet your specific contractor safety awareness level orientation needs. Accessed through the web, or delivered by a third party, PowerSafe provides up-to-date training to your contractors’ employees. With PowerSafe, you know that your contractors have been trained to the same standard.

Partnership to Increase Operations and Maintenance Capabilities

Wamar International, Inc., a U.S. corporation founded in 1983 with its headquarters located in Simi Valley, California, and Primesouth, with its headquarters in Columbia, South Carolina, have merged their individual capabilities through Wamar International acquiring controlling interest of Primesouth. This new alliance will allow the two companies to serve their customer base even better by being able to now offer an extensive spectrum of services under one roof.

Wamar International’s Energy Division provides overhaul, repair, and maintenance services for industrial gas turbines of all sizes, supplying complete turnkey solutions for gas turbine operated power plants and offering major overhaul and repair services for steam turbines and facilities. Primesouth has 20 years experience in providing third-party operations and maintenance services to power, ethanol, biodiesel, and industrial facilities throughout the U.S. and internationally. Primesouth Trade Services, a Primesouth subsidiary, stands ready to provide short- and long-term construction and maintenance labor support specializing in welders, pipe fitters, millwrights, and other industrial construction trades, as well as rapid response teams providing precision millwrights, certified boilermakers, welders, and pipe fitters.

Primesouth’s maintenance and service division offers consulting in the field of preventive, predictive and proactive maintenance, including thermography, lube oil sampling, borescopic inspection, and vibration analysis.

High-Voltage Services

ProEnergy Services recently launched a new division to provide high-voltage services to power generation customers. This new service further expands the company’s single source capabilities, offering innovative power solutions to major energy providers throughout the world. ProEnergy’s High Voltage division gives customers the competitive advantage of speed and technical knowledge through its services related to construction, testing, maintenance, and training of high-voltage substations.

The company’s services include:

• Assembly and installation and commissioning of HV equipment

• Project management for substations and HV services

• Fault analysis

• Maintenance plans, RCM and preventative maintenance

• Custom training programs for operators and maintenance crews

• Infrared inspections

ProEnergy is an integrated service provider that delivers safe, reliable solutions to clients throughout the world. ProEnergy provides a variety of professional services, parts, and equipment to the energy industry. The company has U.S. offices in Sedalia, Mo.; Atlanta; Tulsa; and Houston. Overseas locations are in Argentina, Mexico, Venezuela, Pakistan, Panama, and Ghana.

Q

Boiler Tubes Scanner

Due to the nature of power boilers, accessibility for boiler tube butt weld examinations is limited. With the MetaPhase Helix scanner, Q.Pro Technical Services is able to quickly and efficiently scan the total circumference of boiler tube butt welds, providing a higher quality examination with instant results. The compact design of the Helix scanner also allows for access in all areas of the boiler with the capability to examine all ranges of thicknesses and diameters.

Due to the close proximity of crafts working simultaneously in the unit, radiography is not a desirable option for these examinations, as it can cause interruptions in adjacent work activities. MetaPhase involves no radioactive materials or devices, enabling production welding teams to work side by side with the inspection crews. Applications for the Helix scanner include: reheat and superheat sections, header replacements, economizer overhauls, and water wall tubes.

R

Logic Tree Knowledge Management Templates

Reliability Center, Inc., announced the availability of their exclusive PROACT® Logic Tree Knowledge Management Templates™ to their suite of PROACT® software products. The templates, developed and owned by Reliability Center, Inc. (RCI), are now available for use in the Root Cause Analysis module. The PROACT Logic Tree Knowledge Management Templates are an aggregation of experience garnered from more than 800 field investigations. The analyses have been thoroughly reviewed and their results compiled to form this unique, single RCA knowledge base.

Analysts can now utilize RCI’s templates, providing a comprehensive knowledge base that can be leveraged to accelerate analysis activities. As RCA teams progress through their analyses related to a particular failure, they can now review additional possibilities made available with the PROACT Logic Tree Knowledge Management Templates. These templates provide analysts with greater visibility into something their team could have missed and can also incorporate previous findings into the current analysis to ensure that appropriate corrective actions are identified.

Engineered Boiler Systems

RENTECH Boiler Systems is an international provider of high-quality, engineered boiler systems with headquarters in Abilene, Texas. RENTECH designs and manufactures its products in Abilene in a state-of-the-art plant spanning nearly 40 acres. We offer excellent technical solutions to the unique needs of the heat recovery steam generators (HRSGs) with a focus on custom engineered products. You can depend on RENTECH boilers for reliable performance because of their quality and unique application to the needs of each customer.

We specialize in, and are the largest supplier of HRSGs for today’s high-efficiency gas turbines that operate in the 3- to 40-MW size range. Our expertise in high-fired applications incorporates full optimization of the duct-burner performance while utilizing catalytic oxidation and SCR for control of emissions for the entire system. Our approach to achieving lower emissions starts with optimization of the HRSG design. Coupled with RENTECH’s knowledge of low emissions burner and in-house catalytic reduction technologies, we are capable of supplying a system that fully complies with all performance criteria and is backed by a single-source emissions guarantee.

Pipe and Cable Utility Locator

With the RIDGID® SeekTech® SR-60 pipe and cable utility locator users can do fast, easy, and accurate locates to protect infrastructure and underground assets. The innovative, easy-to-read display visually maps the signal so users can constantly view the changes in the line direction, depth, and signal strength in real time, increasing efficiency and confidence when on the job site. The unique passive search mode on the SR-60 can be used to search all broadband passive frequencies at once, allowing for easy identification of known and unknown power lines or other metallic lines in the target area.

It is the only utility locator with the capability to receive the full range of locatable frequencies of 10 Hz to 490 kHz. Users can tune the frequency 1 Hz at a time, allowing the SR-60 to be used with any pre-set frequency transmitter or proprietary frequency. RIDGID locators raise the standard in locating equipment. The SR-60 locator uses multi-directional antennas and state-of-the-art processing to provide users with the information they need, when they need it, to effectively and easily locate underground utilities.

Construction Trades Contractor

We here at RMF Nooter strive for continuous improvement through education and experience to better serve our clients and their needs in a positive work environment. We work hard through planning and scheduling to eliminate problems associated with projects of all sizes and structure. Our supervisors aren’t just handed a plan; they help build it. With our multi-crafted talent pool of supervision in boilermakers, pipefitters, millwrights, electricians, and iron workers, we not only have the experience and the technical know-how to do the projects but also utilize trained personnel from the local union halls in the areas in which we work.

We promise to provide our customers the best workmanship available and deliver uncompromising quality in a timely fashion. Our goal is not to meet schedules but to beat them. Our vision is simple and that is “To be our customers’ preferred choice in all the markets we serve.” Our safety department prides itself with safety not being a goal as much as it is a way of life. We boast an EMR of less than .70 since inception.

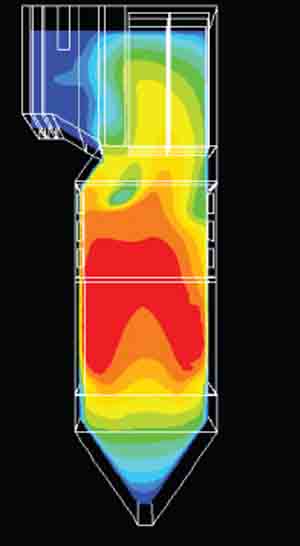

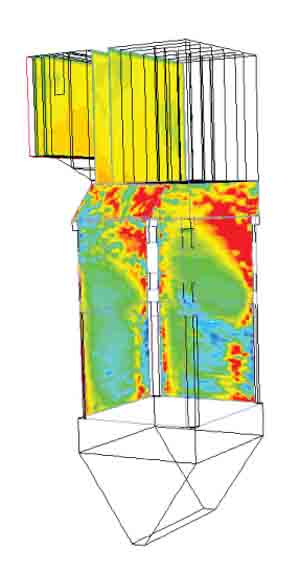

Applied Computational Modeling

RMT’s SmartBurn® group delivers more power and more profit to its power producing clients. We do this by applying a series of products and services emanating from our core capability of Applied Computational Modeling (ACM), an advanced form of CFD modeling. ACM allows us to see into the boiler in a non-invasive way, predict its performance under varying conditions, and consider multiple performance parameters to bring sound financial balance to production and emissions.

Our products and services range from testing, tuning, assessments, and evaluations to physical modifications to the boiler, including RRI, SNCR, OFA, burners, tips, and nozzles. After a physical change, we also test, tune, and commission the new configuration for optimal performance. To ensure sustainable results, we provide training for operators. Our SmartBurn solutions can provide SCR-like performance without the large capital expenditures, the lost output, and monthly operational expenses associated with SCRs. This reduces the risk for clients and allows them to reach their profit objectives more easily. RMT is a proud sponsor of ELECTRIC POWER 2009.

Machinery Laser Alignment

ROTALIGN Ultra now features a larger full-color TFT display readable in sunlight with a faster processor, new user interface and enhanced graphics. As always, achieve alignment results in three easy steps: dimensions, measure, results. Enjoy wireless communication; standard, vector, and user-editable tolerances;, Soft Foot Wizard; standard deviation, and much more.

S

Advanced Elemental Analyzers

SABIA, Inc. the leader in advanced elemental analysis, announced the launch of the SABIA X1 Series—a more compact line of on-belt elemental analyzers and the most recent addition to the SABIA analyzer family. The SABIA X1 Coal Analyzer utilizes PGNA technology and is designed to provide the user with extremely accurate, real-time elemental analysis of a moving stream of coal: run-of-mine, stockpile, or finished product. The SABIA X1 brings improved levels of performance to coal applications and helps the customer eliminate material uncertainty and streamline the decision-making process. Like its predecessor, the analyzer is easy to install as it mounts onto existing conveyor structures without modifications. Analysis results can be accessed in real time from any web browser.

SABIA, Inc. is a privately held firm established in 2000 specializing in materials analysis, and the associated control and quality assurance of industrial processes. SABIA elemental PGNA analyzers, full line of nuclear analyzer services, and software options provide complete solutions for the coal, coal-fired power, cement, and mining industries.

Web-Based EHS Monitoring and Reporting Software

A new customizable version of AIRSWEBTM Environment, Health and Safety (EHS) software from Safety Management Systems, Inc., designed to the rigorous requirements of power and utility companies, is now being implemented by such industry giants as Florida Power & Light Inc. (FPL), Centrica Plc., Alstom Power, and MYR Group.

“Power industry companies must measure up to specific safety and environment-related standards that are more demanding than those of other businesses,” said Philip DeFina, chief operations officer of Safety Management Systems, Inc. “By working closely with clients such as FPL, Centrica, Alstom Power and MYR Group, we’ve developed features that meet and even exceed the requirements and expectations of EHS managers in the power industry.” Our latest power industry clients selected the AIRSWEB system after issuing a detailed RFP and evaluating vendors from all segments of the EHS software industry. They sought a Web-based application because there is no need for software to be installed or upgraded, there are no hardware requirements, and it affords easy collaboration between users in multiple remote locations.

Mobile Digital Recorder

Safety Vision, a global provider of mobile digital video solutions, introduces the RouteRecorder® CF2. This compact, mobile recorder supports two cameras, providing public works industries with quality video. For easy data storage and retrieval, this rugged recorder provides several days’ worth of recording and features the option of a removable CompactFlash card or hard drive. The CompactFlash card allows users to access video data at an affordable price, while significantly reducing storage space. Like the entire RouteRecorder series, the RouteRecorder CF2 has multiple input triggers that activate recording based on user-defined actions. It reliably tracks vital information for each recorded event with an option of GPS mapping. Safety Vision viewing software displays a location map showing where the video was recorded with the GPS feature.

“The RouteRecorder CF2 is an economical yet robust video recorder with an easy to use interface,” states Christopher Fritz, Safety Vision chief technology officer. “It provides optimal recording, superior picture quality, and user-friendly navigation at an affordable price.”

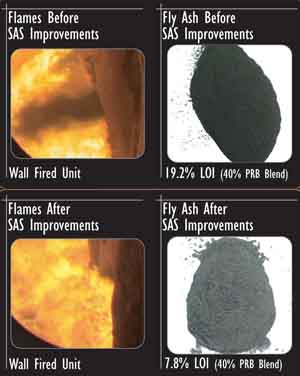

Total Solution Approach for Combustion

SAS Global Corporation is pleased to announce our Total Solution Approach (TSA) to your combustion concerns. Our approach is a custom-tailored solution based upon your specific goals. We will work closely with you to identify potential “opportunities” in combustion improvements that can directly lead to:

• Reduced flyash LOI (50% or more)

• Reduced NOx emissions (20% or more)

• Reduced slagging

• Reduced fuel costs and opacity

• Increased boiler efficiency and generation

• Increased flame stability using our patented In-Line Diffusers

The TSA is unique to each site and is based upon many variables.

Management Consulting Seminar