A continuous emissions monitoring system (CEMS) is required in the U.S. under Environmental Protection Agency (EPA) regulations to continuously collect, record, and report emissions data from industrial facilities, including power plants. The EPA also collects data from gas analyzers, including electrochemical sensors for gases, enabling the agency to conduct investigatory and enforcement activities. CEMS are used to monitor flue gas for emissions such as sulfur oxides (SOx), oxygen (O2), carbon monoxide (CO), carbon dioxide (CO2), mercury (Hg), and nitrogen oxides (NOx). Some of the leading CEMS and gas analyzer manufacturers and suppliers are featured here.

Digital Multigas Analyzer Meets Emissions Challenges

Servomex, a leader in gas analysis, offers a high-performance emissions analyzer, specifically designed for CEMS where legislation requires the measurement of criterion pollutants, greenhouse gases, and reference oxygen. The SERVOPRO 4900 Multigas Analyzer (Figure 1) uses a combination of leading-edge, patented, digital-sensing technologies for ultra-stable, reliable CEMS monitoring of flue gases. It can be configured with a combination of paramagnetic, infrared, and gas filter correlation sensors, and unites high-specification monitoring power with a low cost of ownership. When matched with a suitable sampling system, it is ideal for multiple measurements at MCERTS/QAL1 certification of the pollutants NO, SO 2, and CO, plus O 2. It also measures the greenhouse gases CO 2, nitrogen oxide, and methane with outstanding accuracy. Designed to integrate easily into existing systems, it provides up to four analog outputs, four analog inputs, eight digital inputs, 32 alarms, and 32 relays. Servomex, Egham, Surrey, UK

|

|

1. The SERVOPRO 4900 Multigas Analyzer uses digital-sensing technologies. Courtesy: Servomex |

www.servomex.com

Liquid Analyzer System Is Safe for Hazardous Area Duty

With its sealed explosion-proof enclosure and intrinsically safe sensors, the X80-B88-S88 Liquid Analyzer System (Figure 2) from Electro-Chemical Devices (ECD) now features FM approvals from international insurance carrier FM Global. The system is safe for use in hazardous areas in support of the most demanding applications within oil/gas production sites, refining operations, and storage terminals; chemical processing plants; electric power generation; fertilizer production and storage; and other industries. Wherever potentially explosive or combustible combinations of gases, liquids, and wastewater must be processed and/or treated, the X80-B88-S88 analyzer system is ready to provide highly precise measurement of pH, oxidation-reduction potential (ORP), dissolved oxygen, conductivity, resistivity, or various specific ions. The X80-B88-S88 system features a NEMA 4X, IP66 sealed 316 stainless steel design. ECD’s Model X80 Universal Transmitter is available as either a single- or a dual-channel instrument for continuous measurement with standard MODBUS or optional HART digital bus communications and three optional alarm relays. Electro-Chemical Devices, Anaheim, California

|

|

2. The X80-B88-S88 analyzer system is safe for use in hazardous areas. Courtesy: Electro-Chemical Devices |

www.ecdi.com

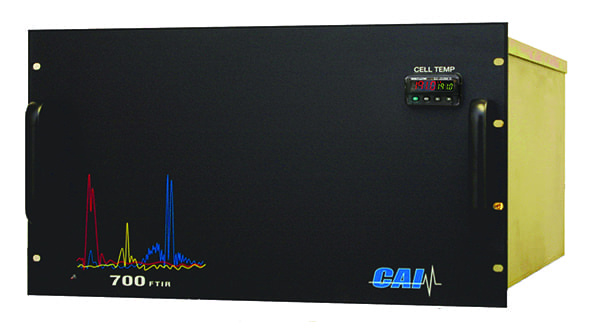

CAI Analyzer Serves Variety of Applications

The California Analytical Instruments (CAI) 7000 FTIR Analyzer (Figure 3) provides fast, continuous, and stable analysis of virtually any gas that has an infrared (IR) absorption spectrum. The proprietary heated sample cell enables the instrument to accommodate hot samples containing high levels of moisture. The 7000 FTIR can serve a variety of analytical applications, including diesel emissions, CEM monitoring, ammonia slip, selective catalytic reduction inlet/outlet monitoring, process monitoring, and others. The 7000 FTIR Analyzer is based on Fourier Transform Infrared Spectroscopy. Nonsymmetrical gas-phase molecules absorb IR light, causing the molecular bonds to stretch, bend, or rotate. This absorption is used to measure and quantify several chemical components simultaneously. The IR radiation is split in an interferometer, where the light is split toward two moving cornercube mirrors. The two beams recombine and pass through a 10.2-meter multi-reflection gas cell where the sample absorbs light at molecule-specific frequencies. The remaining light is measured with a mercury cadmium telluride (MCT) detector and Fourier transformed to convert from the time domain to the frequency domain. This produces a single-beam spectrum that is ratioed with a baseline spectrum, producing an absorbance spectrum. California Analytical Instruments, Orange, California

|

|

3. California Analytical Instruments’ (CAI’s) 7000 FTIR Analyzer provides analysis of virtually any gas with an infrared absorption spectrum. Courtesy: CAI |

www.gasanalyzers.com

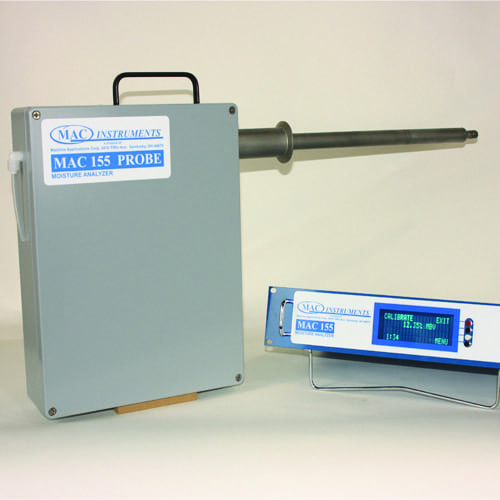

Mac Instruments Touts Easy Installation, Maintenance

Mac Instruments manufactures CEMS products, including analyzers. Product features include stainless steel barrels, aluminum enclosures, two-point calibration, mounting tubes, waterproof, and solid-state design. Mac’s products are designed to be easy to install, and easy to maintain. They feature weatherproof construction to enable indoor or outdoor installation. The MAC 155 moisture/humidity analyzer enables users to augment process safety and comply with EPA regulations. Several high-quality components such as a humidity probe and humidity transmitter combine to make this device exceptionally user-friendly. MAC 155 (Figure 4) is used in industrial operations worldwide for 24/7 monitoring of stack emission gases. It is designed for measuring humidity in exhaust gases in temperature ranges up to 1,200F (650C). Mac Instruments, Sandusky, Ohio

|

|

4. The MAC 155 analyzer monitors stack emission gases. Courtesy: Mac Instruments |