Adaptive Brush Seals Restore Air Preheater Performance

Air preheater (APH) leakage has several negative consequences, including lost revenue. A better design for APH seals has been shown to have several benefits over traditional metal strip seals, including a quick payback.

The gas sealing systems used on rotary, regenerative air preheaters (APHs) have evolved little from the metal strip configuration used on the first Ljungström preheaters nearly a century ago. Metallic strip seals are typically used for radial, axial, and circumferential seals that are exposed to corrosive gases at relatively high temperatures. Steel seal degradation begins soon after installation, and the inevitable result is increased air-to-gas leakage over time, which translates into increased fuel consumption and fan power usage. If you’ve ever experienced “running out of fan,” it’s likely that APH leakage is part of the problem.

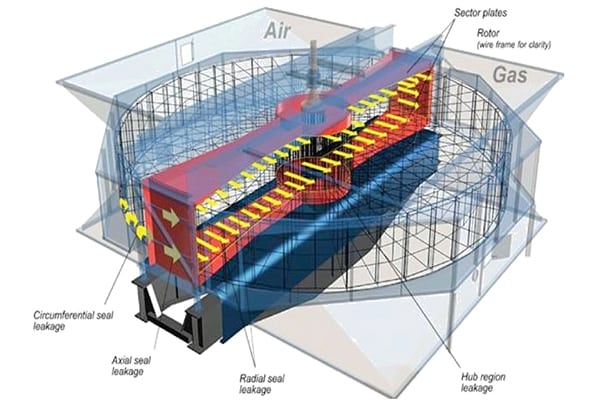

Repeated thermal expansions and contractions in the large (often 20-meter in diameter or more) rotors in continuous motion usually cause large and irregular seal gaps. At operating temperatures, outer edges of large APHs may droop or turn down by 3 inches or more from the cold condition. Steel strips wear (or warp or break) based on the smallest gap size, thus leaving larger gaps elsewhere. Leak rates with properly designed and installed seals should be less than 10%, although leakage rates of 15% to 20% are typical, and rates greater than 30% are not uncommon when conventional seals fail. APH leakages typically occur in air-to-gas and gas-to-air paths through the APH seals (Figure 1).

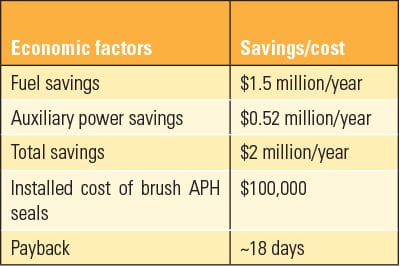

Rotary APHs are particularly critical to the efficient operation of coal-fired power plants, delivering up to 12% of the heat transfer used in the steam generation process. A useful rule of thumb is that for every 20 degree C decrease in the APH gas outlet temperature, boiler efficiency increases about 1%, which translates into about $1.5 million in fuel savings every year for a typical 500-MW plant. An optimally operating APH also reduces fan power consumption and thereby net plant generation capability.

APH leakage also has a detrimental effect on downstream air pollution control equipment due to increased gas velocity, temperature, and APH air- and gas-side pressure drop. For example, the typical flue gas velocity through a selective catalytic reduction (SCR) module is around 5 to 6 meters per second. Increased gas velocity caused by air-to-gas leakage will decrease the residence time of the gas and thereby reduce the effectiveness of the SCR, as well as potentially cause an increase in ammonia injection rates and slip.

Additionally, lower gas residence time in the flue gas desulfurization system can adversely affect lime or limestone injection rates and SO2 removal efficiency. For particulate matter control systems, higher air-to-cloth face velocities in fabric filters can lead to decreased bag life. Pulverizer capacity also can be negatively affected with lower air volumes and temperatures due to air-to-gas leakage.

Brush-up Your APH Seals

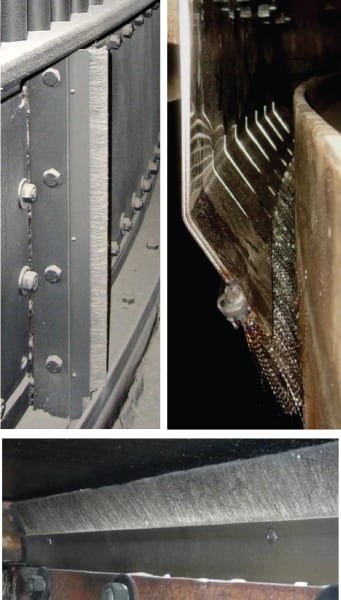

Brush seals are a particularly good choice for replacing steel strips commonly used for circumferential, radial, and axial seals on Ljungström rotary regenerative APHs (Figure 2). Each brush seal consists of thousands of filaments that form a high-integrity seal and provide a high degree of abrasion resistance, flex life, and bend recovery not possible with rigid strip seals (Figure 3). Each bristle is independent and flexible, allowing deflection to conform to any irregularities and gap variations and recover to its original position.

|

| 2. Brush seals installed. Circumferential (left), radial (bottom), and axial brush seals (right) can significantly reduce air preheater leakage rates. Source: Sealeze |

The inherent elasticity of the brush design dissipates stress under deformation, reducing drag and wear. In addition, within the dense barrier of thousands of filaments is an independent and flexible membrane designed for deflection that conforms to any irregularities and gap variations and recovers to its original position to ensure that a tight seal is maintained (Figure 4).

Quantifiable Benefits

Air preheater leakage can account for significant increases in parasitic power draw from the boiler fans, and this translates into lost net revenue.

Consider a typical 500-MW coal-fired unit configured with two APHs originally designed for 10% APH leakage. The unit has combined 8,595 kW installed fan power consisting of two primary, two secondary, and two induced draft fans (excluding the air quality control system). Referring to the fan curves, we find that when the APH leakage increases 10%, the fan power requirements increase 13% (1.12 MW). Table 1 suggests the simple payback for installing brush seals that return the APH leakage to design values can be a matter of days.

There are other significant benefits to using brush seals that aren’t included in Table 1. For example, reducing air leakage on a sustained basis results in lower flue gas velocities and, therefore, reduces the pressure losses in downstream air quality control systems, and results in a corresponding reduction in fan load. For plants with electrostatic precipitators, increased velocities attributable to APH leakage may result in higher dust emissions at the stack. For plants with fabric filters, the higher air-to-cloth ratios due to APH leakage can affect the frequency of bag cleaning and possibly shorten bag life.

Field Performance Results

In June 2007, the Hardin Generating Station, owned by Bicent Power (Hardin, Mont.), contracted with Sealeze, a unit of Jason Inc., to supply its axial and radial stainless steel brush seals for both the hot and cold ends of the 119-MW Unit 1 Ljungström APH. The plant has an average availability of nearly 97%.

Inspection of the brush seals in 2008 showed them to be in very good condition. Some splaying of the brush was evident on the cold end due to sootblower blasts of 205C steam. To prevent direct sootblower impingement, the brush seals mounted in the path of sootblower blasts have been redesigned to incorporate an angled orientation and an integral protective shield.

Since that design update, the brush seals continue to outperform the original steel strip seals more than five years after installation and are expected to continue to perform to specification through at least four outage cycles. During the past five years, the plant has been able to postpone two planned APH outages—another significant cost savings.

Two other brush seal installations have experienced similar results. Radial and circumferential brush seals were installed in 2010 on two 8-m-diameter horizontal APHs at a 300-MW coal-fired unit located in the U.S. (the plant wishes to remain anonymous). The plant reports leakage rates remain well under 10%. In fact, air leakage tests confirmed leakage rates of 5% and 7% on APH-A and APH-B, respectively.

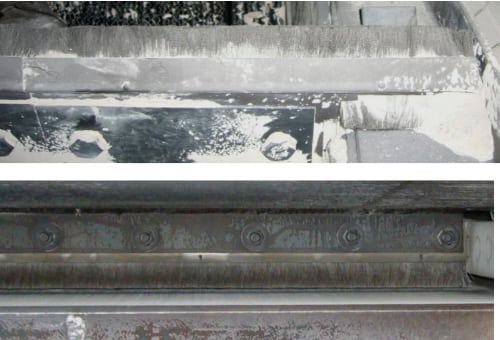

In 2010, radial and axial brush seals were installed on a 10-m-diameter vertical Ljungström APH at a 750-MW coal-fired plant located in the U.S. (this plant also wishes to remain anonymous). Both the radial and axial brush seals remain in excellent condition after more than 2.3 million impacts to the sector plates during 11,760 hours of service over 490 days (Figure 5). The brush profiles remain essentially in the as-installed condition. Seal integrity remains intact as the seal conforms to gap size variations and surface irregularities.

|

| 5. Seal inspections. The radial (top) and axial (bottom) brush seals remain in as-installed condition after 11,760 hours of operation. Source: Sealeze |

APH seal degradation is difficult to identify and is often overlooked as responsible for loss of fan margin, loss in boiler efficiency, and consequential problems with downstream air quality control equipment, particularly the SCR. Chances are your plant is currently troubled by poor APH performance caused by increased seal clearances in the hot condition, seal erosion, inappropriate seal materials, or improper seal settings. Installing stainless steel brush seals is one of the few low-risk, high-reward upgrades that can be easily completed during a typical planned maintenance outage. Better yet, the cost of the stainless steel brush seal retrofit will likely be repaid by improved boiler efficiency quicker than the duration of the outage. ■

—Pavan Ravulaparthy ([email protected]) is business development manager for Sealeze. Ravi Krishnan ([email protected]) is managing director of Krishnan & Associates.