Transporting freight for the energy industry that weighs as much as a house and stretches longer than a city block leaves no room for error. Energy freight shipments, which are often referred to as specialized or dimensional freight, are usually oversized, overweight, and frequently irreplaceable loads that are essential to powering industries and communities.

For the energy sector, dimensional freight is one of the lifelines that moves critical components from factories to job sites. From massive transformers and hydroelectric gates to wind turbines and nuclear reactor parts, these shipments keep infrastructure projects on schedule and make renewable energy expansion possible. According to the Association of American Railroads, moving these critical pieces by rail is a smart choice for economical and sustainable reasons. That’s because moving freight by rail instead of truck reduces emissions by 75%, meaning the clean-energy benefits are multiplied.

Last year, Norfolk Southern partnered with global wind energy leader Vestas to deliver one of the most complex dimensional projects in its history: transporting 158 wind turbine components to the Timbermill Wind farm in Chowan County, North Carolina. This 1,933-acre clean energy site is now operational, featuring 45 turbines generating up to 189 MW.

The project created more than 200 construction jobs and relied heavily on local contractors, with more than $25 million spent with North Carolina businesses during construction. It is projected to generate up to $33 million in tax revenue over its lifetime and is expected to be the county’s largest taxpayer during its first year of operations.

While the shipment itself was a success story, key lessons lie in how the power industry can prepare for the future of complex freight logistics (Figure 1).

Collaboration Is Non-Negotiable

Dimensional freight success begins well before the first shipment moves. For the Timbermill Wind project, Norfolk Southern’s planning started with light detection and ranging (LIDAR) technology-based clearance scans across 10 states, identifying potential obstacles over the 2,000-mile route from Denver to the Port of Morehead City, North Carolina. This proactive engineering approach is essential for:

- Avoiding costly last-minute re-routes.

- Meeting strict construction schedules.

- Maintaining safety compliance in multiple jurisdictions.

Energy developers can reduce risk significantly by bringing transportation providers into the conversation early—ideally during project design—rather than waiting until procurement. Early coordination means the transport plan is built into the project timeline, not added as an afterthought.

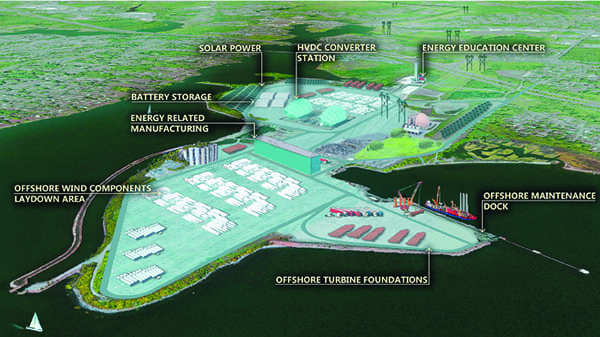

Infrastructure Matters—and Is Changing

In 2024, Norfolk Southern invested $1 billion in infrastructure upgrades, including bridge enhancements and terminal improvements, to strengthen its ability to move freight safely and efficiently. For Timbermill Wind, that investment paid off. It allowed Norfolk Southern to move freight loads as large as entire railcars across varied terrain—something that simply isn’t possible without a robust, well-maintained network. Key infrastructure enablers included:

- Specialized railcars built to accommodate the dimensions and weight of wind turbine components.

- A unique delivery route guided by a coordinated traffic and signage removal plan into the Port of Morehead City, where train cars carrying turbine components traveled directly down tracks that split a four-lane highway in two.

- Partnerships across Norfolk Southern’s network and coordination with Carolina Coastal Railway for last-mile delivery.

Selecting a transportation partner with a strong capital investment strategy ensures that today’s infrastructure can support tomorrow’s freight demands—especially as components for renewable projects grow in size and complexity (Figure 2).

Cross-Functional Teams Ensure Precision

A project of this size calls on nearly every part of an organization. At Norfolk Southern, Timbermill Wind mobilized:

- Clearance and Engineering for route design and hazard mitigation.

- Commercial, Customer Service, Logistics, and Network Operations Center for real-time tracking and seamless coordination.

- Short Line for collaboration with other railroads.

Every step was deliberate, from selecting train crews with high-wide, sensitive freight experience to timing train spacing so that these oversized shipments moved without interfering with other network operations. When timelines are tight and cargo is irreplaceable, a coordinated, cross-functional approach is essential.

Local Benefits for North Carolina Communities

Beyond its logistical complexity, the Timbermill Wind project represents a significant step forward for communities in northeastern North Carolina. The renewable energy site is expected to generate enough electricity to power tens of thousands of homes, providing cleaner, more reliable energy for residents and contribute to the state’s ambitious renewable energy goals.

The project also delivers immediate and long-term economic benefits. During construction, local contractors, trucking companies, and port operations all supported the movement and installation of turbine components, bringing jobs and new revenue to the region. Over the life of the wind farm, ongoing operations and maintenance will provide additional employment while generating tax revenue to support schools, infrastructure, and community services.

Environmental benefits are equally important. Timbermill Wind helps cut emissions, creating healthier communities. Rail played a key role in these outcomes: by moving the majority of components by train instead of trucks alone, the project reduced highway congestion and further lowered the carbon footprint of the supply chain.

A Blueprint for the Future

Moving wind turbines, transformers, and other oversized components isn’t just a logistical challenge—it’s a strategic enabler of the clean energy future. Rail’s ability to carry multiple large loads in one trip reduces highway congestion, lowers emissions, and provides a level of reliability that trucking alone cannot match. On average, rail is three to four times more fuel efficient than highway alternatives, making it both an operational and environmental advantage for clean energy developers.

The Timbermill Wind project was a milestone in Norfolk Southern’s partnership with Vestas. Timbermill Wind is expected to help meet North Carolina’s growing demand for renewable power, and demonstrate how Norfolk Southern’s experience and network strength makes it a trusted partner for future renewable energy projects. At Norfolk Southern, these moves are not seen as just freight shipments, but as milestones in powering America’s future.

—Kathleen Smith is Industrial Products vice president with Norfolk Southern.