Designing, building, and maintaining the network of power transmission lines and associated infrastructure that delivers electricity across the U.S. is a complex task. It involves disparate components, from thermal power plants using different fuel types, to renewable energy such as solar, wind, and geothermal installations.

Substations are another component, and the use of battery energy storage systems, or BESS, is increasing, offering another engineering challenge. Finding ways to make today’s power grid more reliable and resilient—including building new infrastructure and upgrading existing systems—requires cooperation and collaboration among utilities, power generators, and the engineering groups working in the electric power sector.

Engineering Design & Testing Corp. (EDT), a forensic engineering group with dozens of licensed professional engineers (P.E.) across the U.S., works with a range of clients in the power industry. The company offers technical expertise to solve technical and often complex problems associated with power generation and delivery.

A group of professional engineers (P.E.) with EDT provided POWER with insight about reliability enhancements to the nation’s electricity delivery system, looking at how maintenance, repairs, and more can improve the transmission grid and power generation equipment. The group includes Britt C. Hager, Chris S. Spies, and Scott S. Cramer, consulting engineers, along with Gary W. Mullis, M.Eng., P.E., district engineering manager and consulting engineer.

POWER: What enhancements can be made to an electricity transmission and distribution system and/or a power plant (thermal or renewable) to improve its reliability?

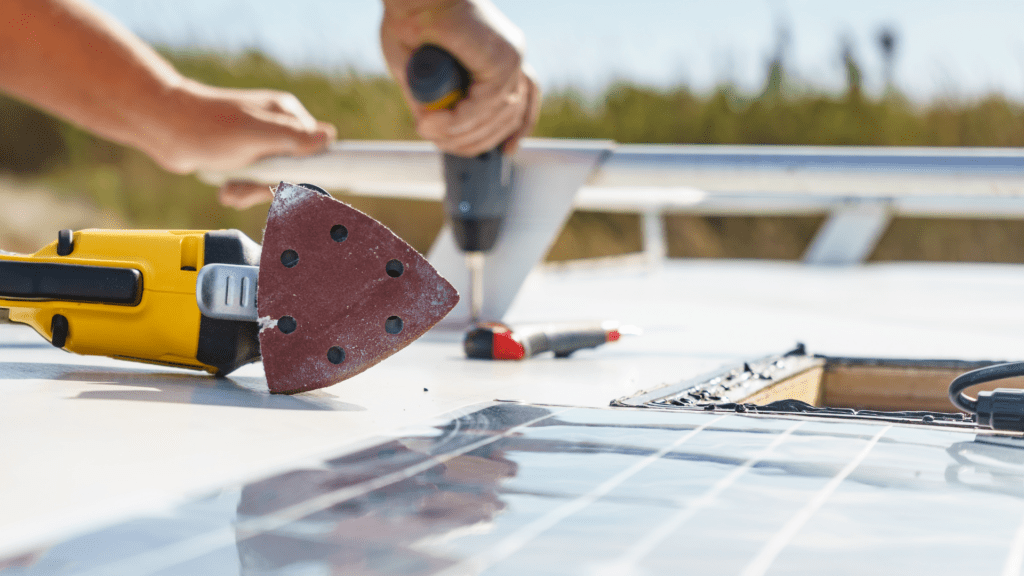

Hager: There are two significant components to the reliability of electrical systems. Design and maintenance. A system designed without regard to operation and maintenance will not be reliable. For example, a rooftop commercial solar design that maximizes output but leaves no room between rows will encourage maintenance technicians to walk on modules, thus shortening the system’s life. And the best-designed systems will not be reliable without regular maintenance (Figure 1). An example would be a central inverter in a solar field filled with dust because it was never taken offline to clean, which will not be reliable.

Tie breakers in Main-Tie-Main type distribution systems are often neglected in maintenance. The circuit breakers used to tie two buses together are energized during normal maintenance, at least on one side, to provide backup power to another bus, preventing cleaning and testing of the tie circuit breaker. The automatic transfer function of the system is also easily missed in testing. It is not uncommon to find a transfer switch bypassed or set to manual unknowingly until a power outage when it does not transfer. Alternate power sources are critical to reliability and should be tested as often as standard sources.

Spies: Many of the key items needed to ensure the reliability of wind turbines are in place, however, when operators fail to take advantage of them, problems often result. Modern CMS (condition monitoring systems) are very effective at providing early identification of anomalies relating to gearbox components. When CMS systems generate alerts, a prompt response by the operators can be the difference between a minor and a major repair. Timely completion of PMs is also necessary (for gearboxes in particular) as the conditions of lubricants can diminish considerably if change intervals are prolonged. In addition to regular changes, analysis of drained lubricants can also provide critical insights into the health of gearbox components.

Cramer: Step-up, MPT, and Substation Transformers across the U.S. are aging and are approaching or have exceeded their expected applicable life age. A proactive plan to replace the aged transformers is critical to avoid long-term outages and/or decreased operating options. Repair and replacement options are increasing in cost and lead time as the demand for replacing failed and aged units continues to increase. Until replacement, one-line monitoring of the critical transformers and conventional oil testing is essential in order to confirm that the transformers are not on the brink of catastrophic failure and are staying as cool and dry as possible. IR scanning of connected equipment, vibration testing, and partial discharge testing should also be considered.

POWER: What are some of the maintenance programs that can be implemented to make a power plant and/or a power grid more reliable? How can this maintenance be automated?

Hager: Regular inverter maintenance is critical in solar arrays (Figure 2) with central-type inverters. Many of these inverters are in hot, dusty, almost desert-like environments. Regular filter cleaning and attention to fan operation are crucial to the longevity of a large inverter.

Transformer maintenance varies by size, but all oil-filled units should have dissolved gas analysis performed at least once per year. High-voltage bushings should be tested for power factor and capacitance. If the transformer connections are in air terminal chambers, it is important to clean, inspect, and keep them sealed from wildlife.

The solar industry will be a prime candidate for automated maintenance. Drones are already used for infrared scanning and can be programmed with automated flight paths. Drones can also be used for solar module cleaning and will become more effective over time. Grass cutting can be automated in large solar arrays spanning thousands of acres. Online monitoring devices such as partial discharge, vibration, flux probes, and others are other primate candidates for automated monitoring and alerting to problems in electrical apparatus such as transformers and generators.

Cramer: Online gas-in-oil analysis would be a form of automation that could predict the health of transformers. Protection schemes for transformers need to be periodically checked for proper response to faults in the system. Too often, the protection scheme fails to open upstream and/or upstream equipment, and smaller failures become catastrophic.

POWER: How necessary is redundancy as part of power plant/power grid operations? How can operations be standardized to improve reliability?

Mullis: The average U.S. customer loses power for 214 minutes per year. That implies the U.S. utility grid (Figure 3) is 99.959% reliable. Surprisingly, that places the U.S. at the bottom of the industrialized nations for power reliability. A 2024 report prepared for the Kleinman Center for Energy Policy concluded that the “primary cause of our unreliable grid is …a failure of grid governance” and that the solution was for Congress to vest more authority in the Federal Energy Regulatory Commission (FERC) to write and enforce reliability standards. On the other hand, a report prepared for the National Renewable Energy Laboratory concludes that “the cause of an outage typically is not related to the bulk power system and takes place within a mile or two of your house, like a tree limb falling on a local power line.” Depending on who you ask, the best person to improve the power grid’s reliability is a Washington (D.C.) lobbyist or a lineman with a chainsaw.

These two perspectives are not mutually exclusive or even competing ideas; they are the reality of the goal of improving the reliability of the electric utility system from 99.959% reliable (outages totaling 214 minutes per year) to the holy grail of reliability “five 9s“or 99.999% reliable (5 minutes and 15 seconds per year). The effort required to meet the five 9s gold standard will involve legislation empowering regulators, executive leadership freeing capital for modernization, front-line engineers improving protection and coordination schemes, and tree-trimming companies keeping the right-of-way clear. There is no one approach to squeeze the last 0.04 % out of the tube.

POWER: What are some of the specific components/equipment that can be used to enhance reliability?

Spies: As noted above, fitment of Condition Monitoring Systems to equipment, analysis of drained lubricants, and timely completion of maintenance can all enhance reliability. One should also not hesitate to invest in high-quality lubricants. High-quality base oils combined with additive packages optimized for a particular application can meaningfully extend the usable life of a piece of equipment.

Hager: In addition, microprocessor-based relays allow much more visibility into power systems. Taking advantage of the remote monitoring capabilities of system parameters can provide early warning signs to system operators of problems. These relays have digital and analog input/output capabilities that can monitor apparatus such as transformers or inverters without needing separate PLCs or SCADA systems.

Cramer: Features within the relays are too often unutilized within unmanned substations. Using more features could be accomplished a minimal cost as a remote “ general alarm” requiring further inquiry to resolve a specific issue.

POWER: How can a program enable proactive replacement/restoration of older equipment (both software and hardware) in power plants and power grid systems?

Hager: Components, such as circuit breakers and relays, can be removed and replaced one at a time. As a circuit breaker is removed, a spare is installed, and the removed breaker is rebuilt. The following maintenance window allows the replacement of the next breaker, and so on. The outage time required is much lower than a wholesale replacement of parts. Costs can also be spread over multiple budget cycles.

Prefabricating relay cabinets and switchgear doors can decrease outage times dramatically. If the field wiring and switchgear structures are sound, mechanical relaying can be upgraded to digital relaying by removing a switchgear or panel door and installing a new door with relays already installed and wired to terminal blocks.

Regardless of the equipment, the highest priority of proactive replacement or restoration in systems must be planning. Engineering hours upfront pay dividends during a limited maintenance window when drawings match the field terminals, transformers match the height of the cable terminations, and temporary power procedures have been established.

—Darrell Proctor is a senior editor for POWER.