Valves in production plants are exposed to incredibly hazardous operating conditions each day, which are further magnified by pressurized and erosive wet steam. Proper valve specification and maintenance are vitally…

Valves in production plants are exposed to incredibly hazardous operating conditions each day, which are further magnified by pressurized and erosive wet steam. Proper valve specification and maintenance are vitally…

Power plants depend on hundreds of valves and many different pumps to carry out operations 24/7. Good maintenance procedures—including routine tasks and predictive maintenance—are critical to keeping these assets online…

When a power plant experiences issues with performance, the obvious indicators are usually a loss in load capacity or an increase in fuel consumption. However, other issues exist that can…

BREA, CA – July 14, 2023 – Curtiss-Wright’s Nuclear division announced today that its Brea, CA facility has received ISO 9001:2015 certification for its quality management system (QMS). This globally-recognized…

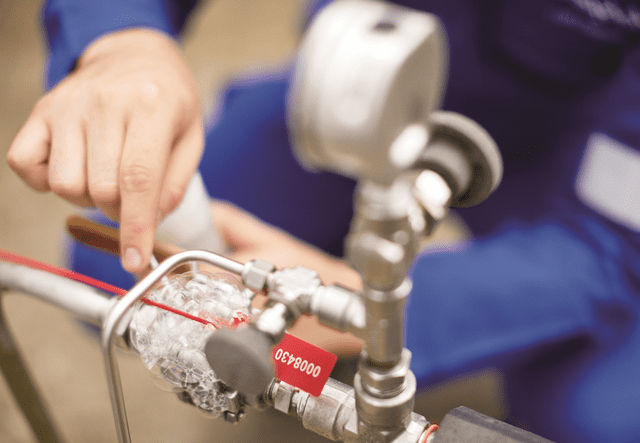

Though discussions of fugitive emissions are not new in power and processing facilities, they remain a focal point of most plants’ operational plans because they can harm profitability if they…

Accelerates Flowserve’s 3D Strategy and provides meaningful aftermarket revenues Velan brings a highly complementary valve portfolio to Flowserve’s FCD segment Transaction expected to be accretive to Flowserve’s Adjusted EPS in…

Since 1958, Check-All Valve® Mfg. Co. has manufactured a complete line of spring-loaded piston-type check valves, also known as silent check valves. We service customers all over the world in…

For use in concentrated solar power plants DALLAS, Oct. 26, 2022 – Flowserve Corporation (NYSE: FLS), a leading provider of flow control products and services for the global infrastructure markets,…

Company Marks Milestone by Growing Workforce on Cleveland’s West Side SOLON, OHIO—Swagelok Company, a leading solutions provider of fluid system products, assemblies, and related services, is marking its 75th year…

CIRCOR International, Inc., a leading manufacturer and marketer of differentiated technology products and sub-systems, highlights its broad range of pumps and valves product technologies for the hydrogen economy. High pressure…