The thermal utilization of sustainable fuels and the recovery of waste heat play a central role in today’s energy generation and the decarbonization of the global industry. Industrial boilers are the backbone of this transition and provide steam for district heating, process applications, and electricity generation.

To unleash their potential, boilers must operate cleanly and remain free from fouling and deposits, which are carried as fly ash by polluted flue gas. Even thin layers of fouling on boiler tubes significantly impair heat transfer, reducing efficiency and overall performance. In many plants, fouling leads to unexpected shutdowns or force operations to run at reduced load—causing avoidable costs, lower output, and planning uncertainties.

Availability and efficiency are the decisive levers that drive higher energy yield, lower operating costs, and reliable planning.

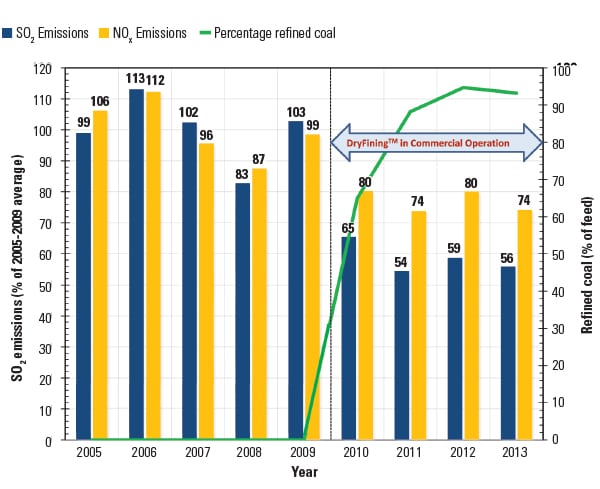

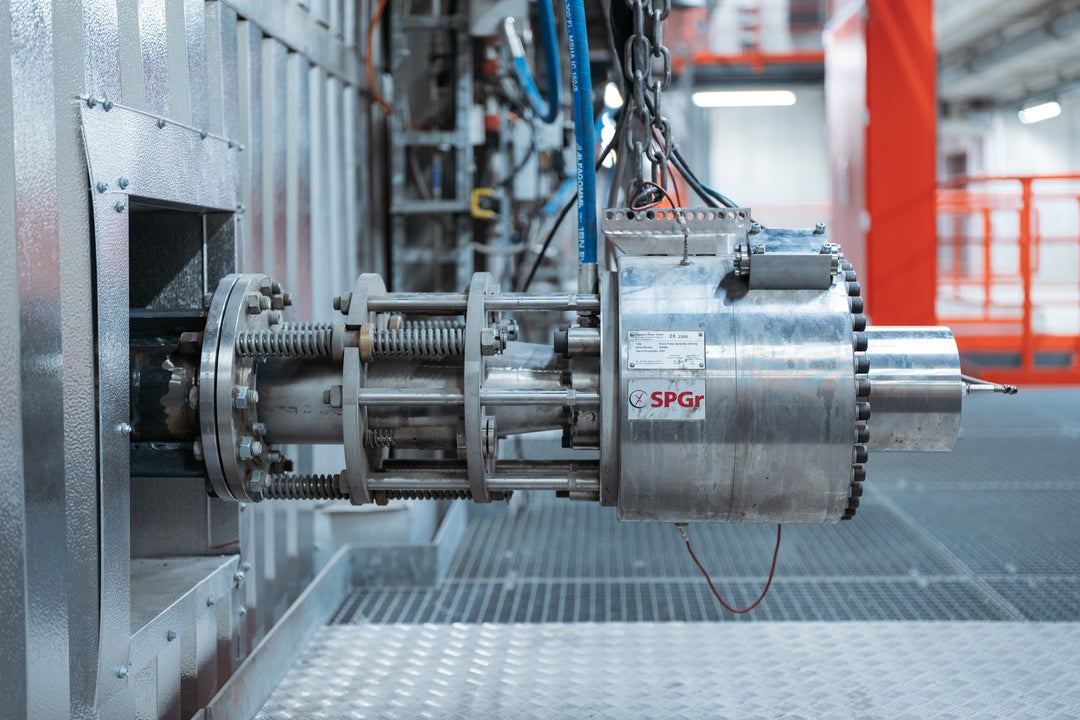

The risks are silent, but costly: unplanned shutdowns with severe downtime expenses, reduced efficiency that means less energy and more emissions, and the burden of expensive manual cleaning and maintenance. This is precisely where shock pulse technology makes the difference. Using targeted shock pulses generated from controlled gas combustion, the system cleans boilers reliably, safely, and efficiently—without interrupting operations (Figure 1).

Watch the video to see how shock pulse technology provides automated, consistent cleaning for optimal boiler performance.

Shock Pulse Generators (SPGs) developed and manufactured by Explosion Power GmbH enable efficient boiler cleaning for various steam boiler applications in the field of waste incineration, biomass power plants, coal-fired power plants, smelting plants, refineries, and many more.

Shock pulse cleaning is intended to keep the tube bundles clean from the start of the operating period rather than being applied only after heavy fouling has built up. This also allows an increase in boiler load and throughput, and improves the overall performance of the plant. SPGs are easy to retrofit to optimize existing boilers, but also increasingly used for new build plants. More than 1,300 units have already been delivered worldwide by Explosion Power GmbH.

Area of Use

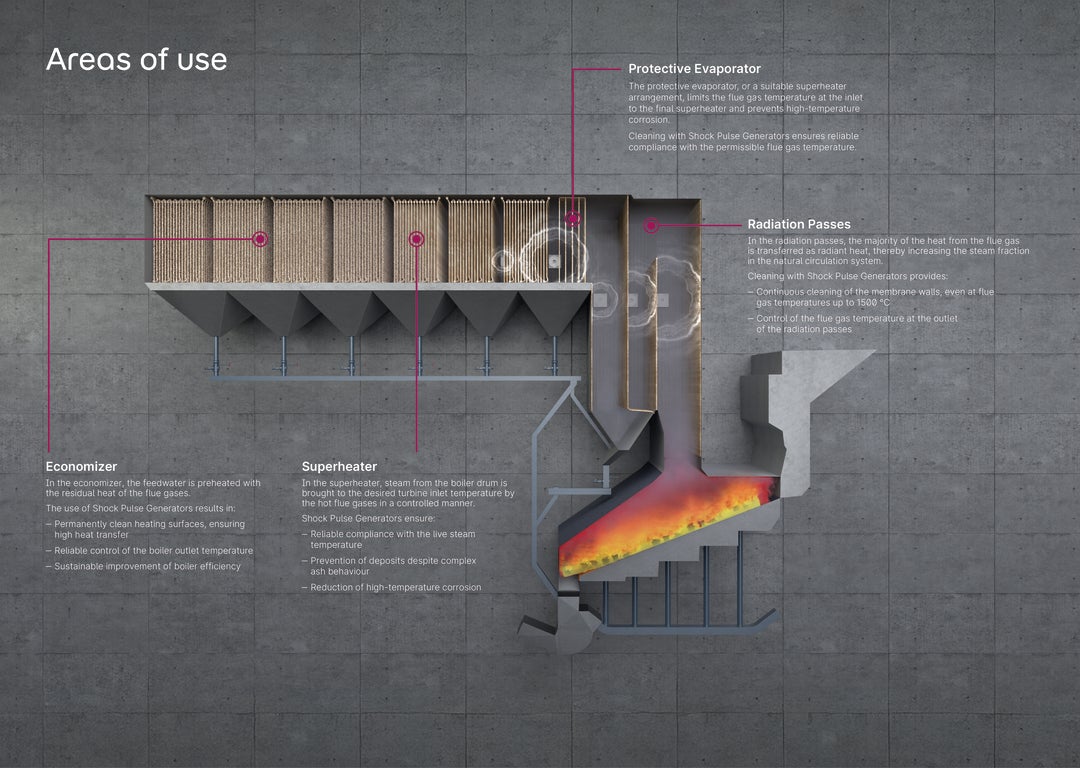

The pressure wave generated by the Shock Pulse Generator, shown in the visualization below (Figure 2), is introduced into the boiler, where it induces a structure-borne wave within the deposits and sets the tube bundles and walls into vibration. This removes fouling and deposits, and ensures efficient heat transfer.

The areas of use for Shock Pulse Generators extend across the entire range of industrial boilers and steam generators. The diagram above shows a schematic representation of the boiler in a waste-to-energy (WtE) plant. The technology is successfully applied in a wide variety of other power plant types and boiler designs.

Compared with conventional steam-based sootblowing systems, the Shock Pulse Generator achieves effective cleaning while consuming significantly less energy. Process steam can thus be used in its entirety for energy generation and does not have to be wasted on cleaning the boiler. Shock pulses are gentle on the tube bundles and do not generate any additional water ingress into the process. This is advantageous in terms of corrosion. Compared with the widely used manual explosive cleaning techniques where detonation is used for cleaning, shock pulse technology offers a significantly higher safety level, as it is fully automated and eliminates all manual activity and the handling of hazardous substances such as explosives.

In addition, the technology is clearly distinct from many other cleaning methods that cause abrasion of tubes, loss of valuable steam, uncontrolled discharge of cleaning media, mechanical damage to striking systems, or large temperature fluctuations combined with increased flue gas moisture and higher risk of clogging and operational failures.

Working Principle

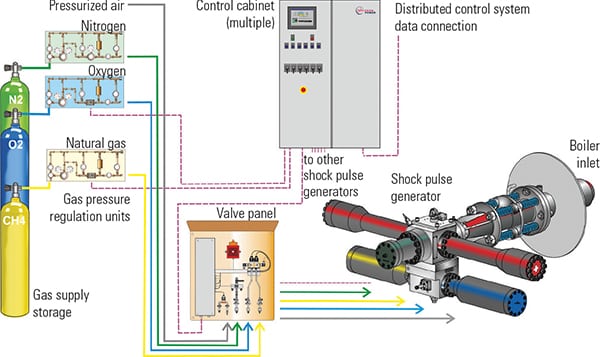

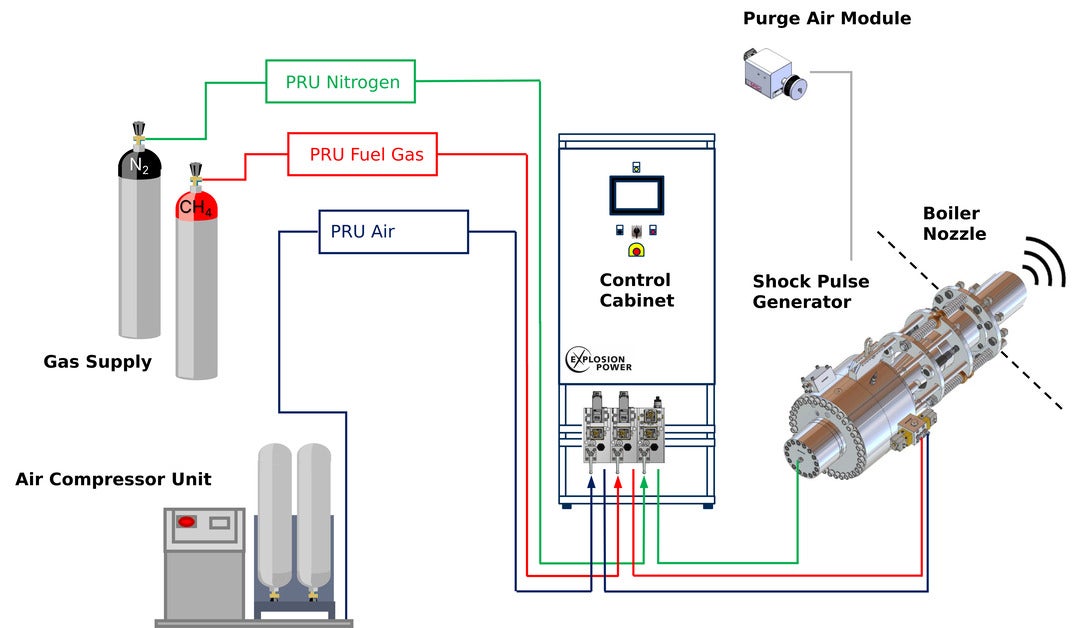

Combustible gas (methane or natural gas) and high-pressure compressed air are supplied through pressure-regulating units and a valve arrangement to ensure proper simultaneous dosing in the combustion chamber and creating the correct gas mixture for ignition by a glow plug. Pressure transmitters perform the necessary switching and monitoring functions.

Once the glow plug initiates combustion, a piston mechanism opens the combustion chamber, and the shock pulse is released through a nozzle into the boiler. This pulse generates a spherical wave, which is introduced into the boiler, setting the flue gas flow and the heating surfaces into brief vibration, while simultaneously inducing a structure-borne oscillation within the deposits. Through these combined mechanisms, fouling is efficiently removed from tube bundles in the boiler.

Nitrogen is used for the closing mechanism and for sealing the combustion chamber. After the shock pulse exits the unit, nitrogen pressure pushes the piston forward again, closing the outlet. A purge air ventilation unit is used to flush the nozzle, protecting it from the harsh conditions inside the boiler.

The cycles are controlled by a programmable logic controller (PLC) located in the control cabinet, which is ready for integration into the operator’s distributed control system (DCS).

The Shock Pulse Generator is mounted externally on the boiler’s membrane wall, with the discharge nozzle guided into the boiler interior through a nozzle connection or a manhole.

Depending on the degree of fouling inside the boiler, the operator can select an appropriate shock-pulse pattern. The intensity of the shock pulse can be varied by adjusting the filling pressure before combustion.

The SPGr series, which operates using compressed air rather than the oxygen employed in previous models, offers several technical advantages. No oxygen is required, as an associated air compressor supplies the amounts of air needed for the stoichiometric combustion of a few grams of natural gas or methane per shock pulse. Less aggressive combustion conditions allow the maintenance interval to be extended. The air supply is provided by an included air compressor unit that is optimally matched for use with the SPGr series (Figure 3).

To ensure the highest safety standards, all Shock Pulse Generators are CE-certified and come with an EU Declaration of Conformity in accordance with the Pressure Equipment Directive (PED) 2014/68/EU.

Optimal cleaning performance is achieved across all types of fouling and deposits throughout the entire application range by precisely matching the system parameters to the boiler design. The selection of the appropriate SPGr type ensures effective cleaning for boiler widths of up to approximately 28 meters in double-sided installations and up to about 14 meters in single-sided configurations. In addition, the correct nozzle size enables optimal flow dynamics and cleaning impact.

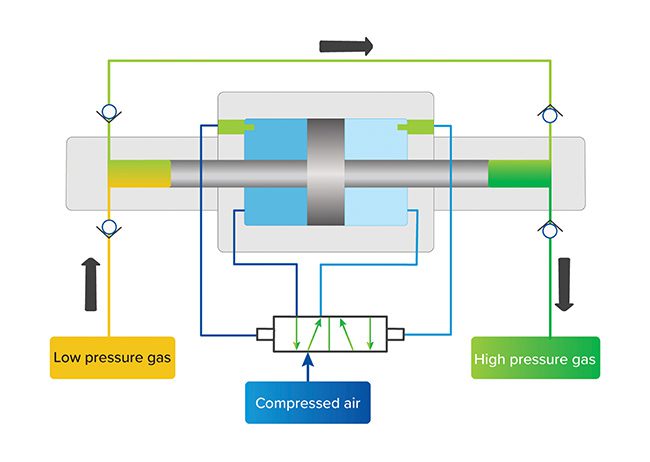

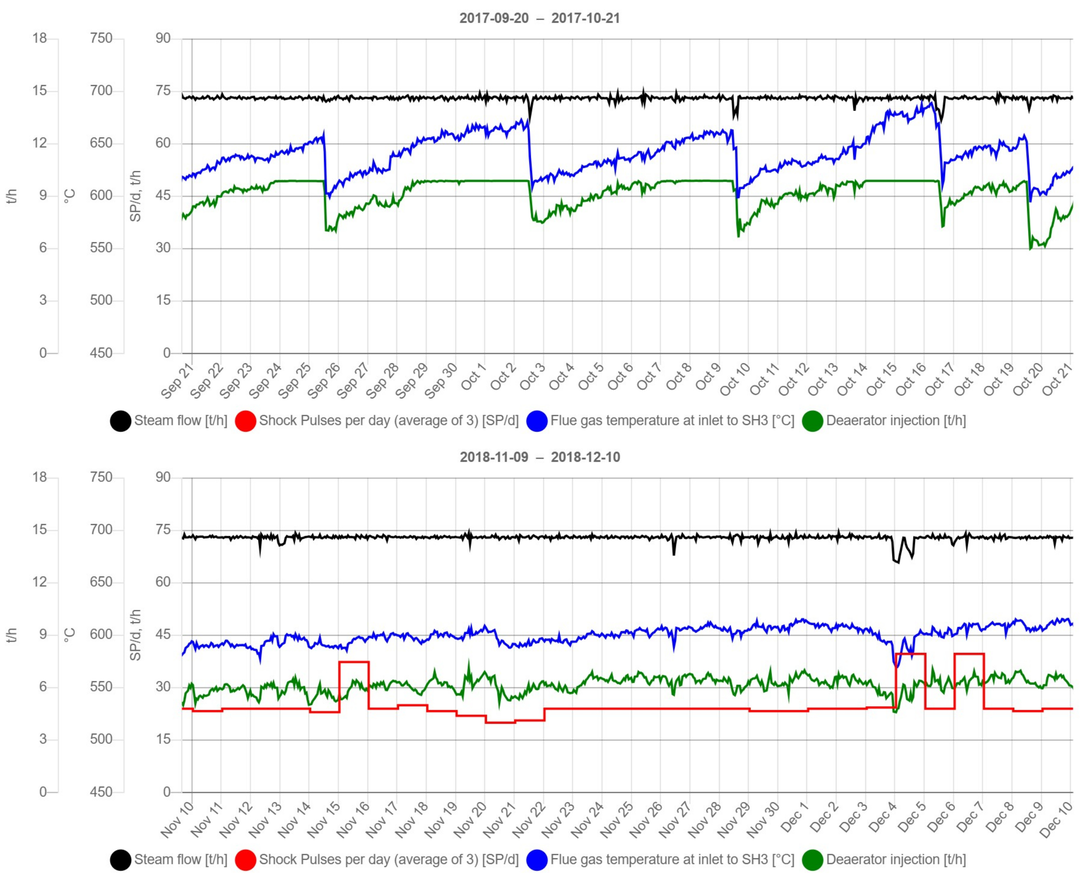

Efficient Heat Transfer and Stable Flue Gas Temperatures

The use of Shock Pulse Generators enhances heat transfer and ensures a low and stable flue gas temperature at the required location in the boiler. The trends below (Figure 4) show a boiler analysis used to determine the necessary cleaning intensity to achieve the desired temperature. Through analysis by Explosion Power and the application of Shock Pulse Generators, a significant reduction in both average and peak flue gas temperatures at the transition to the superheater was achieved. The typical fluctuating sawtooth profile of the flue gas temperature, caused by the use of a traditional shower cleaning system (SCS), was completely eliminated. The installed Shock Pulse Generators clean automatically, consistently, and safely. This allows the plant operator to benefit from more efficient operation, extended operating periods, and, in many cases, an increased capacity.

Using digital boiler models, Explosion Power GmbH can analyze your operating data with precision. Based on this data, they create a digital twin of your plant. This allows engineers to evaluate boiler operation over time and provide targeted recommendations for the optimal use of the Shock Pulse Generators. This enables plant operators to achieve more efficient operation with reduced CO2 emissions, longer operating cycles, and even increased capacity.

Explosion Power GmbH provides innovative solutions for sustainable boiler performance through automated boiler cleaning in thermal waste treatment and power plant applications. Since 2009, Explosion Power GmbH have successfully installed more than 1,300 Shock Pulse Generators worldwide.

—This article was contributed by Explosion Power GmbH (explosionpower.ch).