Focus on O&M

-

O&M

Managing Minimum Load

Reducing the minimum load at which a steam turbine can reliably operate is one way to increase revenue for marginal base-loaded units during periods of low electrical demand. For this reason, it is not unusual to see merchant plants operating at "super minimum" load levels that are well below the typical 25% rated full-load limits. However, such units are operating well outside the original equipment manufacturer (OEM) design basis, and owners may experience undesirable damage to their turbines for a number of reasons. That’s why it is important for owners to understand the trade-offs and risks that come with such operation.

-

O&M

Polymeric Solution for Pump Cavitation

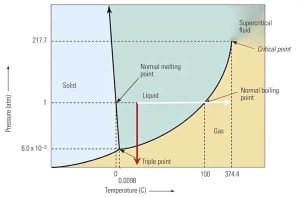

Cavitation is defined as the phenomenon of forming and imploding vapor bubbles in a region where the pressure of the liquid falls below its vapor pressure. Cavitation and the resultant damage can occur in any fluid-handling equipment, especially in pumps. Technological advances in industrial protective coatings and composite repair materials have made it possible to repair pumps operating in a cavitating environment rather than simply replacing them after damage occurs. Cavitation-resistant (CR) elastomers have the ability to retain adhesion under long-term immersion, dissipate energy created under high-intensity cavitation, and provide outstanding resistance to corrosion and other forms of erosion.

-

O&M

Extreme Oil Changes

Performing regular oil changes on remote generators is far from simple or cost-effective. Here’s how one firm harnessed technology to extend oil change intervals from one week to two months.

-

Business

How Company Size Affects NERC Compliance

In the world of North American Electric Reliability Corp. (NERC) Reliability Standards, each company (entity) that must comply with the standards determines for itself the scope and size of its compliance program, based on the scope and size of its operations.

-

O&M

Optimize Gas Turbine Performance Using Acoustic Simulation Software

Increasingly fierce competition driven by deregulation and privatization is putting downward pressure on power plant operations and maintenance (O&M) budgets. Recently, lower natural gas prices have pushed natural gas – fired combined-cycle plants higher up in many utilities’ dispatch order in some regions, a welcome change from the twice-a-day cycling experienced by some plants during the past few years. However, with more operating hours comes more interest in plant operating availability, and that means increased emphasis on reliable gas turbine operation.

-

O&M

Nuclear: Realistic Simulation Assists in Nuclear Power Plant Certification

From the onset of the civilian nuclear era (marked by President Dwight Eisenhower’s "Atoms for Peace" speech to the United Nations in 1953), there has been a strong awareness of the importance of safety within the nuclear energy industry. Western experts have devoted much time and effort to ensuring the integrity of reactor cores and […]

-

O&M

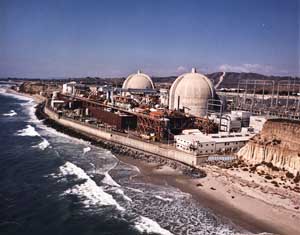

Steam Turbines: San Onofre Nuclear Generating Station Gets Upgraded Generator Rotors

Southern California Edison’s (SCE) 2,250-MWe San Onofre Nuclear Generating Station (SONGS) recently took receipt of a new and upgraded generator rotor for one of its two Alstom steam turbine generator units (Figure 1). Following the successful installation and flawless start-up of this new rotor in the Unit 2 generator, the former Unit 2 rotor was […]

-

Coal

New Federal Rules for Coal Ash Storage on the Horizon

By the end of this year, U.S. power plants with coal ash surface impoundments could face new federal regulations related to the management of coal ash at their facilities. Currently, there are no federal requirements governing coal ash management because in 2000 the U.S. Environmental Protection Agency (EPA) determined it to be a nonhazardous waste under the federal Resource Conservation and Recovery Act.

-

O&M

Making the Most of Thermal Imaging Data

This article discusses planning, operation, and documentation procedures designed to effectively use the thermal imaging camera as a critical element in an effective reliability program.

-

O&M

Reducing Millirem Exposure

Radioactive materials are clinging to the inside walls of reactor system components because of a noble metals injection process error some years ago at Cooper Nuclear Station (CNS). CNS has launched an aggressive, long-term program to remove the materials, but until the work is successfully completed, the station is also taking extensive measures to protect employees and reduce higher source term dose.