Partner Content

-

Partner Content

The Digital Power Plant of the Future: Realizing Operational Excellence

Sponsored by:

Maximized operations. Complete, fully connected and instantaneously accessible operational data. Constant opportunities to leverage descriptive, predictive and prescriptive analytics that drive effective decision-making in everything from evaluating alarms to improving Health, Safety and Environment (HSE) initiatives. Automation that saves time by reducing the repetition of manual processes and human error. A journey based on operational […]

-

Partner Content

Enhancing Grid Resilience and Wildfire Mitigation with TESCO’s Backup Power Transfer Meter (BPTM)

Sponsored by:TESCOEnhancing Grid Resilience and Wildfire Mitigation Discover TESCO’s Breakthrough in Emergency Power Metering Whitepaper: Enhancing Grid Resilience and Wildfire Mitigation with TESCO’s Backup Power Transfer Meter (BPTM)Published: June 9, 2025Fill out the form to access the full whitepaper Gain Confidence in Your Backup Power Strategy As climate-driven outages grow more frequent, utility leaders face mounting […]

-

Partner Content

Predictive Approach to Resin Exhaustion Monitoring in Power Plants

Sponsored by:

Monitoring and controlling highly corrosive contaminants in power water cycle chemistry can significantly impact efficiency, meeting turbine warranty requirements, and more importantly, plant safety. Furthermore, regeneration costs for acid, caustic, rinse water, and labor are considerable. A unique, deionization capacity monitoring algorithm from METTLER TOLEDO monitors the exchange capacity of DI systems and accurately predicts […]

-

Partner Content

Why the Changing World of Power Generation Demands Digitalization

Sponsored by:

The power industry has changed remarkably over the past few decades. A single distributed network has heavily evolved to encompass decarbonization, decentralization and digitalization. Today, power companies are managing not only the traditional baseload systems – such as coal- or gas-fired power stations – but also renewables. The decarbonatization drive is here to stay and […]

-

Partner Content

New employee safety training protects propane and butane businesses

Sponsored by:

In a growing industry, hiring new employees is a routine practice. Those new workers are vital to your company’s future, but they also present a significant safety risk. How significant? According to OSHA, 40 percent of employees injured at work have been on the job for less than one year. In fact, newly hired employees […]

-

Partner Content

How & Why to Prevent Cavitation in Piping Systems

Sponsored by:

Cavitation is a hot topic for engineers, maintenance professionals, and anyone who works with pumping systems—and for good reason. This condition has complicated and difficult-to-identify causes, and its effects can be devastating to equipment, system integrity and overall operations. Preventing cavitation is a full-team effort when it comes to systems operated with centrifugal pumps. It […]

-

Partner Content

Recommissioning Legacy Turbine Control Systems for Enhanced Reliability

Sponsored by:

Increases in renewable energy on the power grid have increased the need for reliable peaking power. In many cases, these assets are available but less reliable than they once were due to the age and neglect of their control systems. In most cases, refurbishment of digital systems from the last 30 years is a viable […]

-

Partner Content

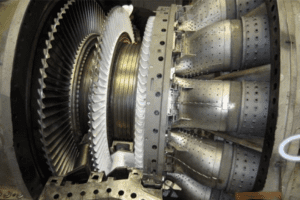

Coordinated 7FA Hot Gas Path and 7FH2 Generator Inspection and Repair

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) completed a carefully coordinated 7FA gas turbine hot gas path inspection, 7FH2 generator inspection and repairs in just 19 days, providing all services, labor, and parts. The customer contracted MD&A to perform the inspection and emergent repairs on a tight schedule. Our industry experts completed the work on time maintaining full customer communication […]

-

Partner Content

POWER Talks with GE Digital

Watch the full interview with Steve Deskevich, VP Product Management at GE Digital

-

Partner Content

EthosEnergy Rolls Out Remote Operations and Monitoring Center

Company’s Performance Center Provides Real-Time Start-Stop Remote Operations Combined with Asset Monitoring and Diagnostics and Remote Engineering Support (Houston) March 14, 2024 – EthosEnergy is taking the next step in its Turning on Tomorrow strategy to improve the customer experience and the future of energy performance. Located in Houston, Texas, the Performance Center gives […]

-

Partner Content

Accurate Carbon Emissions Insights to Support Your Net-Zero Strategy

Sponsored by:GE VernovaEmpower your energy transition with a clear picture of your carbon emissions. Break down siloes between sustainability managers and plant teams and connect monitoring with action. Learn more about CERius™ from GE Vernova, new intuitive emissions management software that helps energy companies measure, manage, and operationalize data insights to track carbon reduction against commitments. With […]

-

Partner Content

Corrosion Prevention with On-line Chloride and Sulfate Monitoring

Sponsored by:

Chloride and sulfate are highly corrosive ions when present in the water/steam cycle of a power plant. They can damage critical components such as turbines, boilers and steam generator tubes, which can lead to unplanned shutdowns and reduced power generation efficiency. METTLER TOLEDO Thorntonʼs 3000CS Chloride/Sulfate Analyzer is an accurate and reliable, online analyzer for […]

-

Partner Content

Bucket Replacement for Non-Native Bucket

MD&A was commissioned by a major U.S. utility to conduct a time-sensitive replacement for a non-native steam turbine bucket. The unit had previously received an OEM-supplied bucket upgrade, which created challenges for the customer. Since this was a modified unit, standard documentation was not sufficient. MD&A was able to leverage our deep experience within the industry to […]

-

Partner Content

TOC Monitoring in Power & Cogeneration Plants

Sponsored by:

Total Organic Carbon (TOC) is one of the most commonly overlooked contaminants in today’s power generation and industrial cogeneration. Controlling organics is important and is especially critical in cogeneration power/steam cycles, where the purified condensate water returning from production processes is subject to organic contamination. Organics present in power plant waters have a number of […]

-

Partner Content

How Nuclear O&M Is Evolving for the Emerging Power Paradigm

In its quest to drive down costs while boosting safety, the nuclear industry has ramped up efforts to streamline operations and maintenance (O&M). New approaches target efficiency and resilience. If there is an underreported trend in nuclear, it has been the global sector’s dramatic reduction in generating costs over the past decade. In 2022, the […]

-

Partner Content

Black & Veatch Congratulates POWER Magazine’s Top Renewable Power Plants

Power generation companies are continually looking for ways to make their operations more cost-effective, in part by seeking out investments that will bolster the bottom line while maintaining their commitment to provide customers with reliable electricity. Many of those utilities want to take advantage of renewable energy resources, making cleaner energy a larger piece of […]

-

Partner Content

Is it Possible to Turnaround a Turnaround?

Sponsored by:

By Paul Muir, CRO, Mobideo Why are Turnarounds So Challenging “A large turnaround can include up to 150,000 individual activities. With this level of complexity, approximately half of all shutdown projects are delayed by more than 20% and 80% go over budget by more than 10%. Frequently, the work scope increases unexpectedly by up to […]

-

Partner Content

Controlling Cost with Control Room Ergonomics

Sponsored by:

Ergonomics The unseen team member of your control room. For organizations, it’s a matter of health and safety. It is also an issue of efficiency and overall productivity. Regardless of how companies measure the importance of comfort and function in their space, many organizations struggle to balance the need for highly ergonomic control rooms with […]

-

Partner Content

Xcel Energy pioneering bridge between nuclear and the hydrogen economy

Sponsored by:

A new frontier for nuclear energy in the United States is under exploration, and Xcel Energy is at the forefront with a project to produce hydrogen, most likely at its Prairie Island plant near Red Wing, Minnesota. “Our carbon-free nuclear fleet has been key to our energy system for decades,” said Pat Burke, vice president […]

-

Partner Content

Aligning with the Right Fabrication Partner at the Right Time is Critical

Sponsored by:

The process for aligning not only with the right fabrication partner, but considering the variables and hurdles at the outset of your project, are critical steps in ensuring your projects success. When these variables are not considered early on, they can result in significant delays in project completion, and can be costly. Design Stage Engagement […]

-

Partner Content

When Disaster Strikes, Utility Solar Asset Owners Turn to Recovery Experts

Sponsored by:

Minimize losses with DEPCOM Power’s unique blend of restoration expertise and EPC/O&M strengths By Jessica Super, VP—Business Development, DEPCOM Power From storm surges to tornadoes and wildfires, natural disasters can wreak havoc on solar power infrastructure — taking out inverters, knocking entire plants offline, and sending owners into a spiral of downtime, repair costs, and […]

-

Partner Content

Protecting the Grid: Securing Meter Data and Systems in the Age of Cyber Threats

Sponsored by:

Executive Summary Electric utilities face unprecedented cybersecurity challenges as attacks grow more frequent, complex, and targeted. Once considered an IT issue, cybersecurity is now central to maintaining grid reliability, customer trust, and regulatory compliance. This white paper examines the critical vulnerabilities within meter data management systems and the operational, financial, and reputational risks utilities face […]

-

Partner Content

Avoiding Potential Productivity Losses with GE Digital Software

Sponsored by:

Responsible energy production across a range of renewable and thermal power generating methods requires a commitment to constant innovation and transformation. Using GE Digital’s Asset Performance Management solutions, Aboitiz Power Corporation, Aboitiz Power Corporation, a vertically integrated leader in power generation, power distribution, and retail electricity services, has improved visibility on critical assets, providing early […]

-

Partner Content

Planning for the Unexpected: Mitigating Business Security Risks Related to Water Treatment Failure

Sponsored by:

By Damon Good, Business Development Manager – Mobile Water Services ANZ, Veolia Water Technologies Water is a critical component of many manufacturing processes and the demand for it is increasing alongside population and industry growth. So, what can manufacturers do if critical water treatment systems fail? Imagine this scenario: It’s Sunday morning and the water […]

-

Partner Content

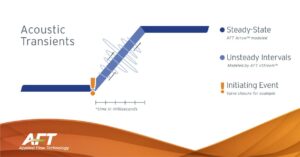

Stop the Guessing Games – Modeling Transient Gases

Sponsored by:

Engineering gas and steam piping systems within power generation facilities is a tough job. Balancing cost, effectiveness, and safety while anticipating changes to design requirements takes a lot of work. Analyzing the gas dynamics of a piping system often occurs exclusively at steady-state, but transient deviations from steady-state should face similar scrutiny in the design […]

-

Partner Content

Portable In-Situ Air Flow Test Stand – Oct. 2021

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) announces Portable In-Situ Air Flow Test stand capabilities that allow for immediate and conclusive data on gas turbine nozzle performance. This flow test apparatus provides efficient gas turbine air/gas flow analysis and is offered by MD&A Fuel Nozzle Services Division/ Integrated Combustion Solutions (ICS). The typical call to action is a control room combustion […]

-

Partner Content

Combined Cycle Overhaul with our One-Stop Shop – Sept. 2021

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) recently completed an overhaul at a combined cycle plant consisting of gas and steam turbine majors, a steam turbine generator minor inspection, and a gas turbine generator major inspection. The customer combined scope was the largest single project implemented at the site since the combined cycle plant was commissioned. MD&A sent all 3 rotors from […]

-

Partner Content

Co-Gen Turbine Controls Retrofit – Nov. 2021

Sponsored by:

Mechanical Dynamics & Analysis’ Control Systems Division (MD&A Control Systems) replaced an industrial co-gen turbine’s original mechanical-hydraulic (MHC) controls with an electronic governor, electro-hydraulic trip system and self-contained control valve actuator. The primary drivers for the project were the operator’s desire to increase the long-term maintainability and reliability by replacing the MHC components that had […]

-

Partner Content

Benefits of Rubber Check Valves for Processing Harsh Fluids

Sponsored by:

Learn how this material choice can help municipalities prepare for extreme weather and other challenging conditions. According to the Center for Climate and Energy Solutions (C2ES), tropical storms have become more common in North America since around 2000. Frequency and intensity vary from basin to basin. In the North Atlantic Basin, the long-term (1966-2009) average […]

-

Partner Content

Global Multiyear Major Outages

Sponsored by:

Mechanical Dynamics & Analysis (MD&A) recently performed multiyear outages for a customer on several different units in Colombia. First unit: This was a major outage and generator test & inspection. In addition, this unit was retrofitted with a new rotor, bearings, and steam path components that required machining, including installing and fitting new nozzles. MD&A […]