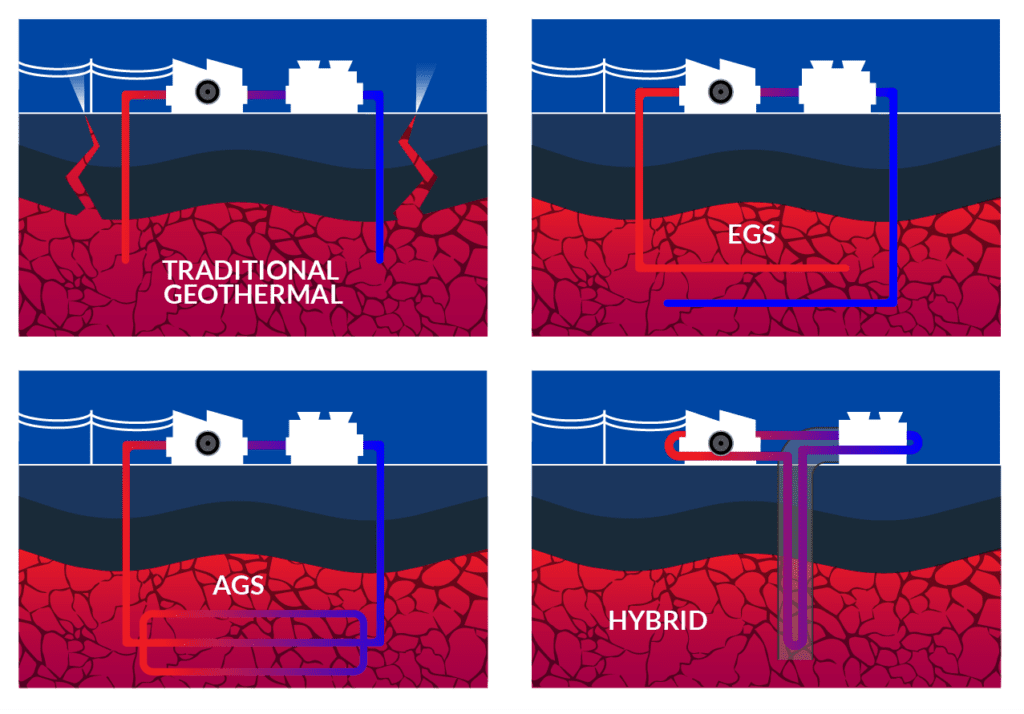

Geothermal energy now stands out as a reliable, low-carbon solution in the transition to a balanced energy mix. While conventional geothermal systems rely on specific geological conditions, such as hot rock, abundant water, and permeability, these conditions only exist in specific regions. As a result, traditional geothermal development faces geographic limits and high capital costs.

Closed-loop geothermal systems extract heat conductively, through the casing, removing the complexity/challenges of fluid exchange with the reservoir, and offer another method of harvesting geothermal energy. They operate in sealed subsurface loops, which allows operators to deploy them in regions that lack traditional hydrothermal reservoirs. With its expertise in drilling and completions, along with advanced drilling and ranging technologies, the oil and gas industry is uniquely positioned to build closed-loop geothermal systems.

How closed-loop systems expand geothermal viability

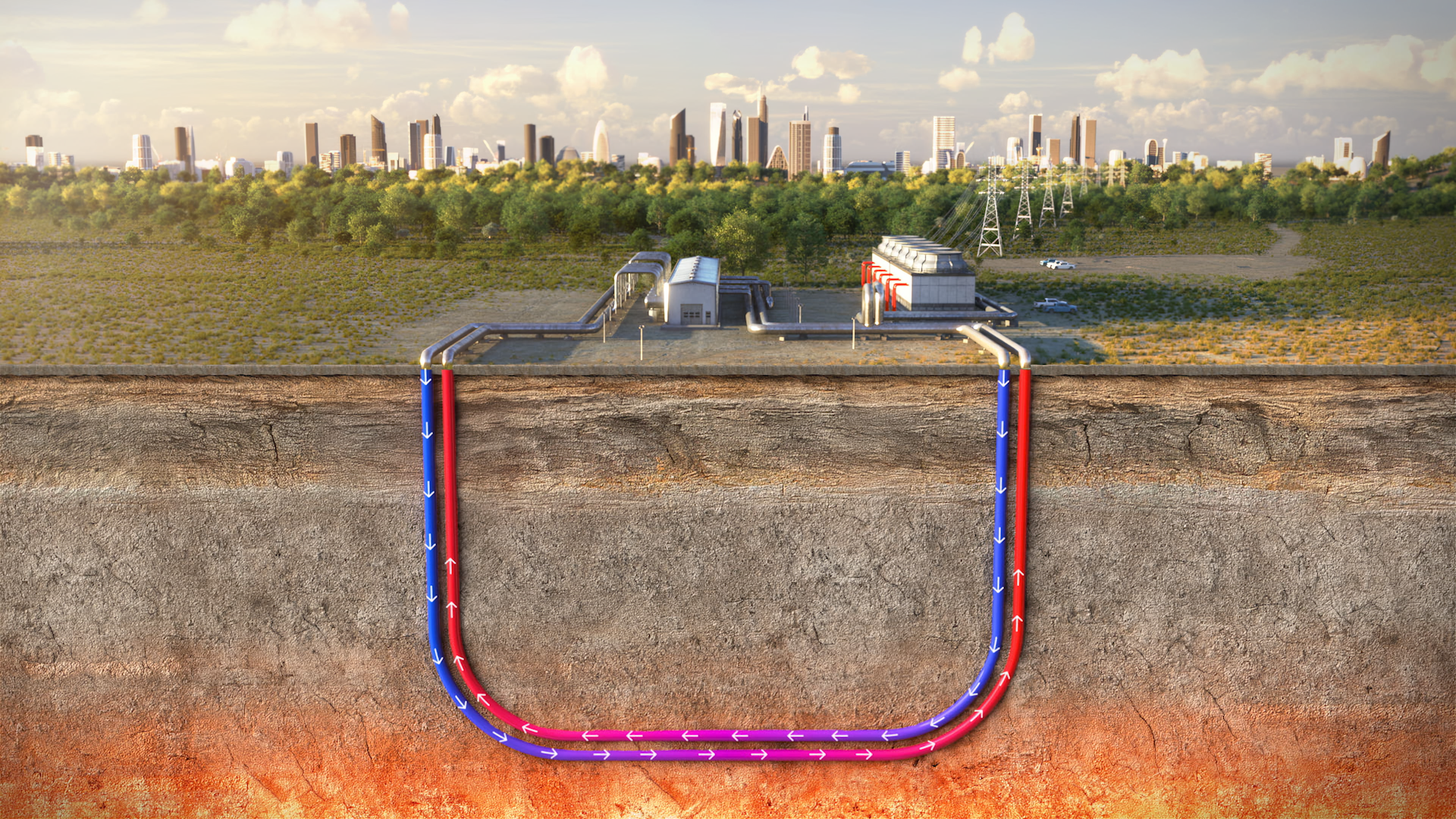

Closed-loop systems circulate fluid through a sealed network of subsurface pipes. The fluid absorbs heat from the rock and carries it to the surface, where it powers turbines or provides direct heating. This approach eliminates the requirement for natural hydrothermal reservoirs and helps operators avoid environmental risks associated with fluid reinjection.

This design simplifies permitting and expands geographic flexibility. Operators can construct systems in sedimentary basins, depleted oil fields, and other locations once considered unsuitable for geothermal development. This flexibility opens new markets and reduces reliance on rare geological conditions.

Several startups have begun the commercialization of closed-loop systems. One example includes a startup that deploys a novel configuration that uses directional drilling and subsurface magnetic ranging to create efficient heat exchange pathways. Another startup has developed a proprietary thermally conductive cement that improves thermal transfer and bolsters system durability. These innovations will help revolutionize closed-loop geothermal production.

Precision drilling makes closed-loop geothermal possible

Closed-loop systems require precise well placement regardless of the configuration. Operators must drill accurate well paths with minimal deviation to land in the target window and/or thread the needle to intersect wellbores. Both configurations demand advanced directional drilling technologies.

High-temperature rotary steerable systems and positive displacement motors support this precision. These tools operate at temperatures up to 392°F (200°C) and use metal-to-metal power sections that resist degradation. Real-time inclination and azimuth data, combined with azimuthal gamma ray sensors, facilitate accurate geosteering and borehole quality control. Halliburton has drilled thousands of parallel wellbores for applications such as steam-assisted gravity drainage relief wells and complex plug-and-abandonment operations that require magnetic ranging technology with products from the RangeStar™ portfolio, including Rotary Magnet Ranging System™,Magnetic Guidance Tool™, and WellSpot® active magnetic ranging system. These projects demonstrate the ability to maintain trajectory control and spacing accuracy in complex subsurface environments.

No-access ranging eliminates dual rig requirements

Traditional geothermal ranging methods often require two rigs to operate at the same time. This approach can double the complexity and cost during non-productive time events. A closed-loop developer can incur incremental costs of $80,000 to $120,000 per day to run dual rigs. This is especially pronounced during legacy ranging operations, which depend on wireline and can introduce flat time into the drilling operations.

Halliburton introduced magnetic ranging in the mid-1980s and refined the technology through extensive field experience. The company’s systems supported critical operations such as relief wells and well avoidance scenarios. Internal ranging protocols emphasize safety and non-intrusive methods, which align well with the environmental goals of geothermal development.

Halliburton commercialized a new ranging technology tailored to the geothermal market, with notable improvements to the current portfolio. The technology places the ranging transmitter and receiver into the drilling assembly, which eliminates the requirement for wireline access in a dual rig scenario. The change reduces flat time during ranging operations to help allow a more efficient drilling operation and reduce overall project costs.

Closed-loop systems provide advantages

Closed-loop geothermal systems offer several economic and operational benefits. The elimination of the dual rig requirement reduces capital expenditure and simplifies logistics. Precision drilling and no-access ranging shorten development timelines and lower exploration risk. Operators can also repurpose current oil and gas assets for geothermal use. Wells that no longer produce hydrocarbons may still offer sufficient thermal energy for closed-loop systems. This reuse strategy extends asset life and supports decarbonization goals.

Closed-loop geothermal systems provide a scalable, efficient path toward geothermal energy, and oil and gas professionals possess the tools and experience to help lead this evolution. Through the application of proven subsurface capabilities to geothermal development, operators can unlock new revenue streams, extend the value of current assets, and position themselves competitively in new energy markets. Closed-loop geothermal supports more than decarbonization goals; it creates profitable opportunities in an emergent energy landscape.

Learn more at Halliburton.com/Geothermal