In This Issue

-

Nuclear

Too Dumb to Meter, Part 8

As the book title Too Dumb to Meter: Follies, Fiascoes, Dead Ends, and Duds on the U.S. Road to Atomic Energy implies, nuclear power has traveled a rough road. In this POWER exclusive, we present the 14th and 15th chapters, “A Man, a Plan, a Canal” and “The End of the Exploding Game,” the final two chapters of “Eddie Teller’s Exploding Ambitions” section.

-

News

Porous Components in a Variety of Refractory Metals

Mott Corp. announced the availability of porous metal components and filters in a variety of refractory metal alloys including zirconium, titanium, tungsten, molybdenum, and niobium. Known for outstanding chemical resistance, high strength, and thermal stability, refractory metals can meet the most demanding operating conditions. Mott can design porous components or entire filter assemblies using refractory […]

-

News

Where’s the Warming?

In case you neglected to mark it on your calendar, the Kyoto Protocol to the U.N. Framework Convention on Climate Change (UNFCC) expired at midnight on New Year’s Eve. The 15-year-old treaty was by every account a failure. Global carbon dioxide emissions are up over 50%, yet global temperatures decreased over the same period. Relying […]

-

News

Powerful Tank-Cleaning Head

The new Torrent 50 tank-cleaning head from NLB Corp. delivers 3-D water jet action with the force of 600 horsepower water, and it fits through a tank or reactor opening as small as 6 inches. The Torrent 50, rated for pressures up to 20,000 psi and flows to 50 gpm, has two high-velocity water jets […]

-

Nuclear

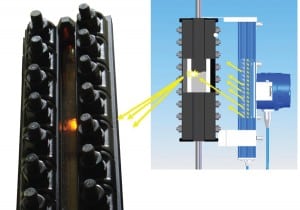

THE BIG PICTURE: Nuclear I&C

Progress in electronics and information technology has created incentives to replace traditional analog instrumentation and control (I&C) systems in nuclear power plants with digital I&C systems, or systems based on computers and microprocessors. About 40% of the world’s operating reactors have been modernized to include at least some digital I&C systems, according to the International […]

-

News

Swing Arm–Mounted, Explosion-Proof Light

Larson Electronics’ Magnalight.com has introduced the HBLP-1MLED-SWAM stainless steel swing arm–mounted, explosion-proof light for wastewater treatment plant applications. Built with 316 stainless steel and equipped with a Class 1 and Class 2 Division 1 10,000-lumen LED light, this adjustable hazardous area light is designed for corrosive environments. The HBLP-1MLED-SWAM is used to position the explosion-proof […]

-

Coal

First U.S. Ultrasupercritical Power Plant in Operation

The U.S. saw the historic start of operations at its first ultrasupercritical coal-fired power plant last December as Southwestern Electric Power Co.’s (SWEPCO’s) 600-MW John W. Turk, Jr. Power Plant switched on in Arkansas.

-

News

Vacuum Cups to Lift Heavy Loads

Large vacuum cups from Vi-Cas Manufacturing are available in sizes up to 15 inches in diameter to lift and manipulate large, bulky, or cumbersome materials, including fabricated assemblies. Round, rectangular, or oval cups are available from stock for a variety of lift manufacturers. Sizes and types are available to fit virtually any type of vacuum […]

-

Nuclear

With Fresh Election, Japan Veers Away from Nuclear Phase-Out

A landslide victory handed by Japanese voters to the Liberal Democratic Party (LDP) in mid-December saw power in the country’s Lower House shift back to the nationalist-conservative party that had governed Japan almost continuously since 1955. The LDP had been ousted in a historic defeat only three years earlier. In his first televised interview since taking office, newly elected Prime Minister Shinzo Abe (who previously served as prime minister from September 2006 to September 2007) called for review of plans to phase out nuclear power in Japan by 2030, endorsing instead the construction of new, safer nuclear power plants.

-

Commentary

The Shale Gas Revolution Continues

The electricity industry is being transformed by the so-called “shale gas revolution” in the United States. Production of natural gas from shale rock using hydraulic fracturing (“fracking”) has boosted supply and reduced prices, making gas-fired power competitive with coal-fired power on price. Historically, coal-fired electricity generation has dwarfed generation from gas-fired plants in the U.S. […]

-

Instrumentation & Controls

Drum Level Instrumentation Update

Accurate knowledge of the water level in any boiler drum application is an absolute necessity. While operating a boiler with low water level is one of the leading causes of boiler failure, operating with a high water level may produce less-than-optimal steam, as well as damage to the steam turbine by moisture carryover.

-

Legal & Regulatory

Is FERC Cracking Down on Market Manipulators?

Last October, the Federal Energy Regulatory Commission (FERC) announced that it was seeking a record $470 million penalty against Barclays Bank for manipulating California energy markets for several years in the late 2000s. The amount includes a $435 million fine as well as disgorgement of $35 million in profits Barclays gained from allegedly illegal trading. In addition, FERC levied hefty fines against several individual Barclays traders.

-

O&M

Layup Practices for Fossil Plants

Improper layup practices are a major contributor to boiler tube failures and to steam turbine pitting and cracking in U.S. fossil plants. EPRI’s research into identifying damage mechanisms, utility best practices, and innovative new methods to protect plant equipment during outages will aid plant operators in achieving a successful layup.

-

Instrumentation & Controls

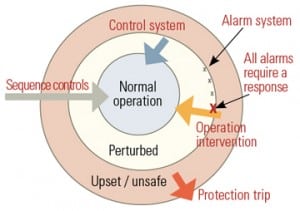

Plant Automation Advancements: The Australian Experience

Many recent utility greenfield and rehabilitation power projects have incorporated plant automation, with the goal of reducing the number of operators needed. The essential design principle is to specify control systems and field devices that will achieve the desired operational regime. Here’s how it’s done “Down Under.”

-

Instrumentation & Controls

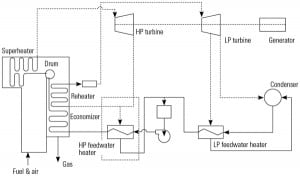

Coordinated Feedwater Heater Energy Control

The increased use of intermittent renewable energy sources and the shift to gas-fired combustion turbines places new burdens on the dispatch of many coal-fired units. Steam units must now operate at very low minimum load while maintaining the ability to ramp up and down quickly. High-pressure feedwater heater energy control can improve the system response of such coal-fired units.

-

Instrumentation & Controls

Thermocouple Response Time Study for Steam Temperature Control, Part II

Mismatched or poorly maintained temperature sensors and thermowells can cause an often-unrecognized error in steam temperature measurement. The problem is often recognized only when sluggish steam temperature response times are noticed. Recent tests suggest some simple ways to resolve the problem.

-

Environmental

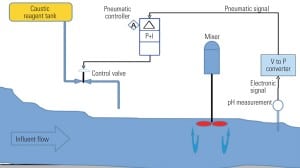

Sediment Pond Effluent pH Control

Many power plants have sediment retention ponds that require control of pH for the effluent. The following guidelines for fossil plant sediment pond pH control will help you design a robust system while staying within budget.

-

Business

Getting Distributed Energy Resources Right

Rick Tempchin, executive director, Retail Energy Services for the Edison Electric Institute, talks about the impact of distributed energy resources on utilities and their customers.

-

Water

A Moderating Tone from the EPA on 316(b)?

Final water intake structure rules from the EPA expected this June suggest the agency may be listening to industry and even moderating its tone. Stretch goals as part of the Section 316(b) rule are likely, but overall the rule may prove more reasonable than many expected.

-

News

Multiprocess Power Source

ESAB Welding & Cutting Products introduced Warrior, a new multiprocess power source and feeder designed for processes including energy generation construction, pipe welding, general fabrication, and repair and maintenance. Designed for GMAW (MIG), FCAW (flux-cored), SMAW (stick), and GTAW (TIG) welding as well as ACAG (arc gouging), Warrior delivers up to 500 amps at 60% […]

-

News

Recovery System for Granular Activated Carbon

The VAC-U-MAX self-contained granular activated carbon (GAC) delivery system is mounted on a self-contained skid. This system is a complete prepackaged dilute phase pneumatic conveyor system to deliver or remove GAC from scrubber towers and holding tanks. Tubular probing wands, convey hose, filter receiver, vacuum pump, and control panel are included. (http://www.vac-u-max.com)