For many years, air pollution control (APC) rules and regulations have governed the design and economics of the world’s power generation fleet. These rules have had a tremendous impact, improving…

Technical articles on all aspects of power plant operation, preventive and predictive maintenance, planned and unplanned outages

For many years, air pollution control (APC) rules and regulations have governed the design and economics of the world’s power generation fleet. These rules have had a tremendous impact, improving…

Safety should always be a priority for any business, no matter the industry. This is particularly true for power generation facilities, which feature multiple pieces of complex machinery that can…

Supports modern plants with the digital transformation of OT and IT environments Combines Voith’s in-depth knowledge of the OT and IIoT domain with Kudelski’s expertise in hardware- and software-based cybersecurity…

Twelve students from across the globe have spent the last six months, five days a week for eight hours a day in Kalamazoo, Michigan at the nation's leading training program…

Applied Flow Technology Releases New Version of Their Waterhammer and Surge Analysis Software Bordeaux, France - November 14, 2018 – Applied Flow Technology President, Trey Walters, P.E., announced the release of AFT…

![Power Plant Control Loop Tuning and Optimization [PODCAST]](https://www.powermag.com/wp-content/uploads/2018/10/power-podcast-art-final.jpeg)

Optimizing power plant control systems can be challenging, but new tools are available to simplify and improve the process. On this episode of The POWER Podcast, Executive Editor Aaron Larson…

Analysis based on testing mostly conducted by energy companies shows that water near all but two coal plants in Illinois is contaminated with toxic waste. The Chicago Tribune on November…

November 2018 – West Chester, PA – Metabo Corporation, a leading international manufacturer of professional grade cordless and corded hand-held power tools and accessories, announces two new tools; 18V Impact…

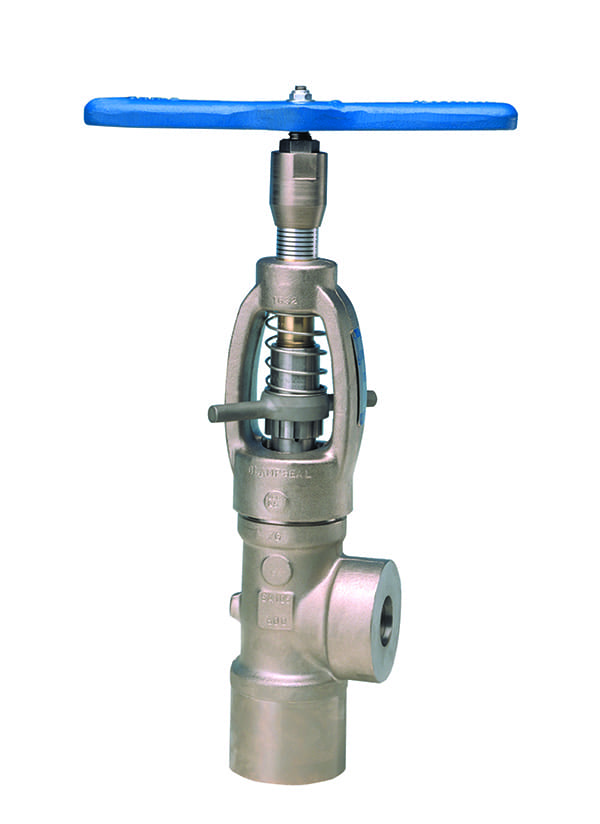

Proper valves, pipes, and fittings are important for successful operation of power generation facilities. This equipment includes products with versatile designs to establish effective joining and sealing methods, and better…

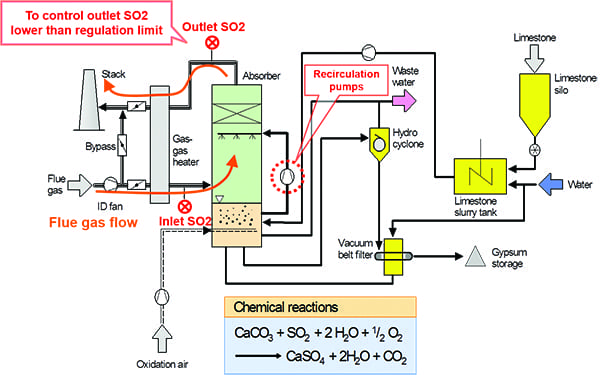

Coal-fired power plants can significantly improve wet limestone scrubbing with advanced process control. One optimization system implemented at a Japanese facility utilized enhanced regulatory control, model-based prediction, and process value…