O&M

-

O&M

Using Radar to Improve Security and Counter Drone Threats

Security is taken very seriously at most power plants. Fences and other barriers are usually installed before construction of a plant even begins to keep curious busy-bodies, thieves, protestors, and—at the far end of the spectrum—saboteurs and terrorists out of sensitive locations. Some plants have dedicated security staff patrolling areas both inside and outside of […]

-

Legal & Regulatory

Is an Automated Compliance Tracking Solution Right for You?

Like so many other power plant functions these days, regulatory and standards compliance can be automated. Know what you want an automated system to do before you make a vendor decision. As North American Electric Reliability Corp. (NERC) Critical Infrastructure Protection (CIP) enforcement deadlines and audit dates loom—notably, CIP-003-6 in April 2017, which addresses the […]

-

O&M

High-Speed Turbine Rotor Balancing Lowers Costs and Improves Operation

High-speed turbine rotor balancing was once rare because of the costs and logistical challenges involved in doing it during an outage. That’s begun to change as economic options emerge, and experience is showing that high-speed balancing can pay big dividends in reliability and maintenance costs. To a maintenance engineer or fleet manager, unwanted vibration in […]

-

O&M

A Primer on Gas Turbine Failure Modes

When a gas turbine goes down, recovery can be an expensive, time-consuming process. Knowing what can go wrong and how to anticipate turbine failures can help you avoid a difficult unplanned outage. Gas-fired power is hot and getting hotter. The Energy Information Administration estimates that 2016 will be the first year ever that the U.S. […]

-

O&M

Efficient Use of Power Plant Process Data Improves Asset Management

Asset data is crucial in the power generation industry. Without it, utilities are forced to speculate about how long their assets will last, when they will need repair, and which strategies will maximize plant efficiency. With it, plant owners have the tools to drive down operational and maintenance costs while ensuring highly reliable power delivery. […]

-

O&M

HRSG Condition Assessments Identify CAPEX, Maintenance Priorities

As combined cycle gas turbine plants are called upon to play a larger and more flexible role in the generation mix, it’s important to schedule a comprehensive assessment of major components at key intervals to ensure reliable operation. Just like humans, power plants can benefit from regularly scheduled condition assessments, which are sometimes called “health […]

-

Partner Content

Sulzer expands facility capability with new lathe

Industrial gas turbines are increasing in size. As a result of this, repair facilities that overhaul and repair these machines must keep pace. One of the key tools is a large lathe. As one of the leading industrial gas turbine and rotor repair providers in the world, Sulzer has recently upgraded its service center in

-

O&M

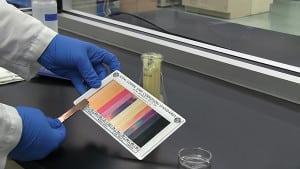

All About Lubricant Additives

Lubricant additive technology is a complicated business because it involves several different chemistries. Often, one additive can adversely interact with another additive as they both compete for the same area on substrate surfaces. This kind of interaction can lead to the canceling of the additives’ desired properties. Conversely, the use of different additive chemistries can, […]

-

Partner Content

Sulzer Service Solutions

Sulzer is the leading worldwide, independent service provider for the repair and maintenance of large rotating machines including turbomachinery, pumps and electro-mechanical equipment. With a global network of technically advanced remanufacturing and test facilities, Sulzer offers a collaborative advantage that delivers high-quality, cost-effective, customized and turnkey solutions, providing its customers with the peace-of-mind to focus

-

Partner Content

Red and green to grey — Why switch my HMI?

Many operators are perfectly happy with their trusty red and green HMIs and can’t imagine why they should give them up for a dull greyscale display. When they take a closer look, they usually find out that grey is beautiful.

-

O&M

Emissions Catalyst Issues for Fast-Start Combined Cycle Power Plants

When gas-fired plants are required to cycle more than they were designed for, added stress on plant components isn’t the only consequence. You also need to pay closer attention to turbine catalyst systems. Traditionally, many combined cycle gas turbine (CCGT) power plant units were designed and permitted for a baseload or similar operating profile. Startups […]

-

O&M

Boiler Tube Failure Thermohydraulic Analysis

Eskom operates 23 power stations in South Africa with a total capacity of more than 42 GW. It supplies about 95% of all the electricity used in the country. One of its coal-fired power stations was experiencing frequent boiler tube fatigue failures in the hopper section—the bottom part of the boiler—of all six units. The […]

-

Legal & Regulatory

How the FAA’s First-Ever Commercial Drone Rules Could Affect Power Companies

The first operational rules finalized by the Federal Aviation Administration (FAA) for routine commercial use of drones could have major implications for utilities and power companies, which are increasingly using them for operations and maintenance. The new rules (Part 107 of the Federal Aviation Regulations) that apply to unmanned aircraft systems (UAS)—or drones—weighing less than […]

-

Partner Content

The Importance of RTO Maintenance

The importance of RTO maintenance

RTOs or Regenerative Thermal Oxidizers control emissions without producing harmful byproducts or hazardous waste. They help destroy volatile organic compounds (VOCs), hazardous air pollutants (HAPs) and other odorous emissions created during normal manufacturing and industrial processes by combusting them into carbon dioxide and water. RTOs pass hot exhaust gas and cooler -

O&M

TVA Backs “In-Place” Coal Ash Impoundment Closure Method Over Removal

The Tennessee Valley Authority (TVA) listed costs and time among several reasons for its preferred method to close its coal ash impoundments in place, rather than by removal, but the move has come under fire by environmental groups. The federally owned corporation earlier this month released a final environmental impact statement (EIS) to support its […]

-

O&M

Managing Multiple Generations Across a Smooth-Running Fleet

Power generators have always had to make afetyome changes as each new generation enters the sector, but today’s new workers are bringing with them attitudes and skills that challenge traditional plant management, for good and ill. Here’s what some companies and plants are doing to make the best use of younger workers while getting them […]

-

O&M

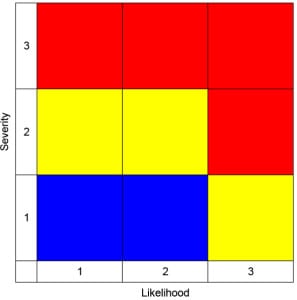

Use Near-Miss Incidents as a Preventive Tool

Broadly put, today’s power plant operations are a mix of automated operations and manual or procedural steps. A plant may have hundreds of control loops, interlocks, permissives, and safety systems. In

-

O&M

Ultrasonic Diagnostic Tool Detects Leaks, Bearing Wear, and Corona Discharge

Air leaks cost money. According to the U.S. Department of Energy (DOE), over $5 billion per year is spent on energy to power compressed air systems. The DOE estimates that optimizing these systems could

-

History

New Thinking on Old Safety Issues

Human workers are imperfect, which is why there’s no magic bullet that will give you a safe workplace. But new research on human behavior and how that translates into safety attitudes is helping some in the power industry get beyond the traditional platitudes. Safety first. Safety is no accident. Be aware—Take care. Those and others […]

-

O&M

Training the Next Generation of Electric Utility Workers

New worker training has traditionally meant classroom instruction and wading through a big pile of printed materials. But videos can offer deeper and more rapid understanding of critical issues, especially for younger generations. The Electric Power Research Institute has developed a series of videos to help power plants train new workers more effectively. Inexperienced new […]

-

O&M

NRC Approves Measurement-Related Uprate at Duke Energy’s Catawba Reactor

Duke Energy’s request to increase the generating capacity of Unit 1 at its Catawba Nuclear Station by 1.7% by more precisely measuring feedwater flow has been approved by federal regulators. Staff at the Nuclear Regulatory Commission (NRC) found on May 4 that Duke Energy could safely increase the reactor’s output “primarily through more accurate means […]

-

O&M

Core Shroud Head Bolt Retainer Tool Saves BWRs Time and Money

A new tool that can be used to help ensure the proper positioning of core shroud head bolt assemblies in boiling water reactors (BWRs) was recently invented by Jason Cocke, engineering, tooling, and logistics

-

O&M

Battery-Monitoring System Improves Safety, Reliability, and Efficiency

When management decided to purchase and install a new, vented lead-acid battery system at the Dogwood power plant, decision-makers also investigated the benefits of adding a continuous battery-monitoring

-

O&M

The Importance of Including Balance-of-Plant Systems in Condenser Maintenance

Keeping a power plant’s surface condenser in proper working order requires paying attention to balance-of-plant systems as well. Failure to monitor and maintain cooling towers and vacuum pumps in particular can lead to performance penalties or worse. The surface condenser at a power plant has a significant effect on power generation—specifically, the efficiency with which […]

-

O&M

Resilience and Change in a Digital Future

Two senior power sector executives opened the 2016 ELECTRIC POWER Conference and Exhibition in New Orleans April 19 with a message that generators need to “think big” and embrace possibilities of disruptive technologies—or risk being run over on the road to the future. Leo Denault, chairman and CEO of Entergy Corp., delivered the opening keynote […]

-

O&M

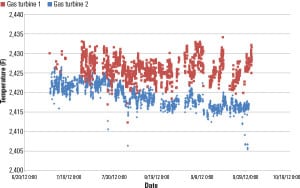

Rigorous Turbine Validation Process Produces Sustained Reliability Exceeding 99%

Why would one want to validate a turbine design? The answer is that actual operation of new and more advanced gas turbines can reveal issues that are very difficult to predict on the drawing board. As a

-

O&M

Covered Piping Systems O&M Programs for CCGT Plants

A great level of risk is present when operating pressurized systems. Over the years, industry safety concerns have increased with the occurence of catastrophic events. To help prevent further loss and damages

-

O&M

New Quality Assurance Program Launched for Wind Turbine Blades

Blades are probably the most delicate part of a wind turbine and the most susceptible to accidental damage. Some estimates suggest that greater than 90% of wind turbine blades are damaged to some degree while

-

O&M

Leveraging Drones and Robots for O&M Savings

If you’re still thinking of drones and robots as more toy than tool, think again. The drones now working in the power sector have gone far beyond remote-control hobbies and now resemble something closer to

-

O&M

Solar PV O&M Best Practices in a Rapidly Changing Market

In 2000, the world had installed just 1 GW of solar photovoltaic (PV) capacity (in DC terms—see the sidebar, “AC or DC?”), a number that had surged to 39 GW by 2010 and 176 GW in 2014. Fueled by