O&M

-

O&M

New Tools for Diagnosing and Troubleshooting Power Plant Equipment Faults

The Electric Power Research Institute has developed a pair of diagnostic tools that combine and integrate features from multiple sources of plant information. The Diagnostic Advisor and the Asset Fault Signature Database will improve diagnostics for and troubleshooting of equipment faults by providing a holistic view of the condition of plant equipment.

-

O&M

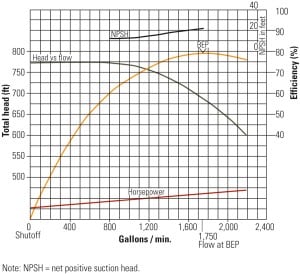

Deferred Maintenance Increases Pump Failures

If your facility has recently seen an upsurge in bearing failures on boiler feedwater (BFW) pumps, you are not the only plant experiencing these unnecessary and costly failures. The failure causes are often elusive, which is why plants have so many unresolved repeat failures.

-

O&M

Power 101: Improving the Performance of Boiler Auxiliaries, Part II

Efficient boiler operation requires boiler auxiliary equipment to operate in harmony. The air preheater, for example, though it has few moving parts, is vital to maintaining efficient boiler performance. In this second installment of our Power 101 series, we examine performance degradation caused by corrosion and fouling of the air preheater that results from the combustion of coal plus the effects of ammonia and sodium bisulfite injection for SO3 mitigation.

-

O&M

Designing Large Package Boilers

Designing large package boilers rated at over 400,000 lb/h steam production is a challenge because of shipping limitations within the U.S. and Canada.

-

O&M

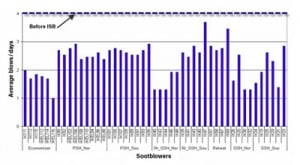

Clinker Minimization at San Miguel Electric Co-Op

San Miguel Electric Cooperative selected and installed an automatic sootblowing system for its Unit 1 to minimize clinkers in the boiler that caused semi-annual unscheduled outages. New boiler surface-cleaning equipment and intelligent cleaning software eliminated these expensive outages.

-

O&M

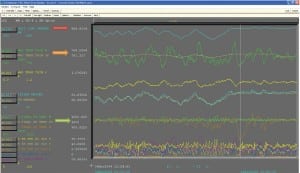

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

O&M

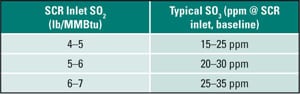

Continuous SO3 Monitoring Can Reduce Sorbent Consumption

An unintended consequence of employing selective catalytic reduction and wet flue gas desulfurization to reduce nitrogen oxide and sulfur dioxide levels at coal-fired power plants has been unwanted sulfur trioxide (SO3) emissions. Picking the right sorbent in the right amount can eliminate that problem.

-

O&M

Exelon Enjoys Benefits of Online Transformer Monitoring

In all of these cases, frequent oil analysis monitoring and preestablished action plans were able to allow for transformer replacement before the occurrence of a catastrophic failure. Exelon’s experience, as well as that of other power utilities across the grid, has spawned a report by the Institute of Nuclear Power Operations (INPO) of Atlanta, Georgia, that recommends that performance monitoring and trending be applied to all large transformers in order to establish a baseline for transformer maintenance strategies.

-

O&M

Selecting a Specialty Accumulator

Sudden bumps and shocks are great fun when you are off-roading or are riding on a rollercoaster. But when you are operating a piece of equipment, you want it to be running as smoothly as a Cadillac rolling down the interstate. Sudden changes in pressure produce vibration, cavitation, and water hammer and generally lower the lifespan and reliability of fluid systems.

-

O&M

EPRI Identifies Four Breakthrough Technologies for 2011

The Electric Power Research Institute (EPRI) has identified four breakthrough technologies and funded them through its Strategic Research and Development Portfolio. EPRI expects to accelerate development of these innovations because they are likely to have significant effects on how electricity is generated and delivered.