The discussion about nuclear fusion has long involved its potential to create limitless amounts of energy. Several companies are working to turn that potential into reality.

POWER’s “Groundbreakers” Special Report, published February 9, includes information from groups at the forefront of fusion research and development. Among those is Thea Energy, a Kearny, New Jersey-based company building what it calls a more economical and scalable version of a stellarator system architecture. Thea Energy officials told POWER it has applied a phased array control system to fusion, which allows for simpler and less-expensive hardware, “and the ability to dynamically tune system performance in the software stack over an asset’s lifetime.”

Thea spun out of the Princeton Plasma Physics Laboratory and Princeton University, where the stellarator was originally invented. The company raised a $20-million Series A in 2024, and was selected as one of eight inaugural awardees of the U.S. Department of Energy’s (DOE’s) Milestone-Based Fusion Development Program.

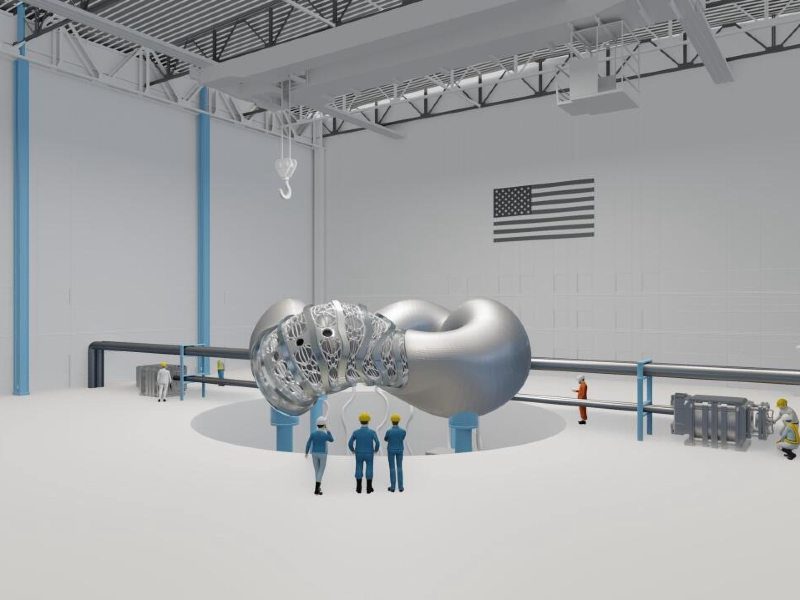

The group’s latest milestone is operation of the world’s first superconducting planar coil magnet array, demonstrating that small and simple electromagnets can practically, precisely, and dynamically create and control stellarator magnetic fields. The company is currently designing and considering siting locations for its first integrated fusion system, Eos, that will produce fusion neutrons at scale and in steady state. The operation of Eos will catalyze the subsequent deployment of fusion energy on the grid via the company’s Helios power plant.

Brian Berzin, co-founder and CEO of Thea Energy, provided POWER with his take on the current landscape for fusion. Berzin talked about his company’s technology its vision for fusion energy.

POWER: Your background includes electrical engineering as well as financial and investment experience. What made you want to become involved with fusion energy?

Berzin: Working in fusion is one of the most consequential and exciting things that one could do with their life and career. I first joined the commercialization-focused side of fusion in 2017, when there were only a few fusion companies, compared to the industry today where there are more than 50.

Since then, the need for clean and abundant fusion energy has reached a tipping point, and enabling technologies such as high-temperature superconductors (HTS) and high-performance computing have further accelerated the commercialization of fusion technology. In the years leading up to joining the field, I had the opportunity to both invest in and operate companies at early and late stages. That foundational experience earlier in my career across other tech sectors allowed us to quickly and efficiently scale our organization and technology to where we are today as a world-leading fusion company.

Thea Energy has developed a fusion architecture that can uniquely scale to deploy energy across the world in a more manufacturable and cost-effective manner. We now have more than 75 people that have joined team Thea in this mission, and that’s only the start.

POWER: What prompted the idea to create the Eos integrated stellarator?

Berzin: The stellarator is a scientifically mature form of fusion technology that was invented at the Princeton Plasma Physics Laboratory, where Thea Energy actually spun out of in 2022. The stellarator system architecture has inherent benefits for commercial fusion power, including highly efficient, steady-state operation, and no risk of damaging disruptions. However, the stellarator’s Achilles’ heel has always been the required complexity and precision of the hardware. The 3-dimensional magnets had to be manufactured and assembled within a millimeter of spec.

We founded Thea Energy to create a more practical stellarator system architecture, engineered for the real world. Our approach uses an array of simpler, programmable magnets. These magnet coils can be mass-manufactured via scalable and economical means. They are wound-in-tension on a machine that looks like an extra-large VCR, leveraging basic manufacturing processes. We then utilize a software-based control system to individually tune these magnets to create the precise magnetic field shaping required for the stellarator geometry. This proprietary architecture is what is being leveraged in our first integrated stellarator “Eos”, and then in the “Helios” fusion power plant.

POWER: How does Eos fit into the strategy to build Helios, a commercial fusion power plant?

Berzin: Eos will create power plant relevant, steady-state fusion using our planar coil architecture. It is an important step toward our first commercial fusion power plant (Helios) as it also de-risks the programmatic and exceptional aspects of building a power plant on time and on budget.

Following Eos, we will be able to quickly deliver multiple power plants to end customers. Eos will also serve as an important facility for the entire fusion industry. During its second operational phase, Eos will be utilized as a neutron source for the development of fusion power plant blanket and fuel cycle technologies, in alignment with the DOE’s Fusion Science and Technology Roadmap.

Via a deuterium-deuterium (D-D) fusion, in this second phase, Eos can also be utilized to breed tritium and important medical radioisotopes.

POWER: You’ve said Thea Energy’s work is more than just a science project, specifically touting a faster path to commercial fusion energy. Why is that important?

Berzin: If fusion is going to be deployed at scale, power plants need to be easier, quicker, and cheaper to build and operate compared to prior scientific systems. The physics basis of the stellarator is well understood thanks to large-scale experiments such as W7-X. We are focused on building off this established physics basis with an architecture that can be manufactured, assembled, and operated more like existing energy infrastructure for combined-cycle natural gas.

Our stellarator architecture utilizes simpler and scalable manufacturing for major components. The software controls that we’ve developed, and already leveraged in our existing magnet systems, further allows for more traditional construction and assembly: if there are hardware or assembly variations, we can just tune them out on the back end at the click of a button. All other stellarator approaches must have perfect manufacturing and assembly for the devices to work, and then those systems must remain in flawless condition over their operational life to function.

That’s just not how things work. Real-world variability and wear and tear is inevitable when you have a system running for 40+ years, especially when it’s creating the harsh multi-mullion-degree conditions for fusion. We now have a way to continually tune system performance over a power plant’s lifetime, enabling high uptime and low maintenance costs. This is the first time that a magnetic confinement fusion system can move beyond the traditional limitations of fixed, complex hardware.

It is important to think about more than just a first-of-a-kind system. We are looking ahead through how we can go down the cost curve using mass-manufacturable components and sector-based sub-assemblies. This approach layered in with dynamic software controls means that we can manufacture components in high throughput facilities, have assembly lines for major subsystems, and then ship those to power plant sites across the world for final integration with a fairly traditinal balance of plant, using local supply chains and constructors.

POWER: Thea Energy has noted “no engineering miracles required” for its technology. How is what your company is doing different from other groups involved in fusion research?

Berzin: A lot of great engineering and execution is involved in building Eos and Helios, but no miracles are required for our magnets, as they are designed within the current limits of HTS technology. Similarly, we are not pushing the boundaries of the other subsystems required within our architecture beyond what has already been achieved across the fusion industry.

Even for what is usually seen as the harder parts of any fusion power plant architecture, like the first wall, we can utilize known alloys and still have a long system lifetime before requiring replacement of certain parts—which is an unsolved challenge for many architectures. We also have a sector-based maintenance scheme that allows easier access to components for scheduled power plant maintenance, and magnets that last the lifetime of the entire plant without requiring replacement.

POWER: What are some of the milestones Thea Energy already has achieved in the fusion energy space?

Berzin: To break it into two major categories, the company has achieved significant progress across core magnet technology performance and manufacturing, as well as its power plant design. In 2025, we designed and operated the world’s first array of superconducBng magnets.

This milestone was fully executed in-house and reflected a tremendous effort from our whole team to prove that stellarators can be built using simpler and more practical hardware. From there, we scaled to manufacture the final Eos-spec superconducting magnets and validated that our manufacturing infrastructure can scale to meet the rate requirements to deliver Eos, and the subsequent deployment of Thea Energy fusion power plants.

At the end of 2025, we unveiled our Helios power plant design. Helios demonstrates a uniquely practical commercial fusion architecture, enabling scalable manufacturing and construction, efficient maintenance, a high capacity factor, and competive economics. This power plant design includes several breakthroughs for commercial fusion energy: a system that combines software-controlled magnet coils that are adaptable to real-world conditions, the world’s first stellarator “divertor” exhaust system capable of fusion power operations, and a sector-based maintenance scheme.

We completed this design review as part of the DOE’s Milestone-Based Fusion Development Program, and we are the first company to receive certification of a fusion power plant preconceptual design. Following this third-party validation from the DOE, we are now making great progress to formalize our engagements with hyperscalers, power offtakers, and commercialization partners for our first Helios power plant.

POWER: What is your company’s timeline to commercialize fusion energy?

Berzin: Thea Energy is on track to operate Eos by 2030. Following that, the company plans to deploy Helios by 2035 using the same planar coil stellarator system architecture. As energy demands rise, fusion is uniquely positioned to provide abundant, on-demand power. We are now working to build the important partnerships across the energy industry to accelerate the scaling of mass-manufacturable and cost-competive fusion power plants around the world.

—Darrell Proctor is a senior editor for POWER.